Three-dimensional porous structure silicon/graphene composite negative electrode material and preparation method thereof

A graphene composite, three-dimensional porous technology, applied in structural parts, battery electrodes, electrical components, etc., can solve the problem of insufficient cycle life of silicon-carbon composite anode materials, and achieve excellent charge-discharge cycle performance and rate performance, good flexible structure. , the effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

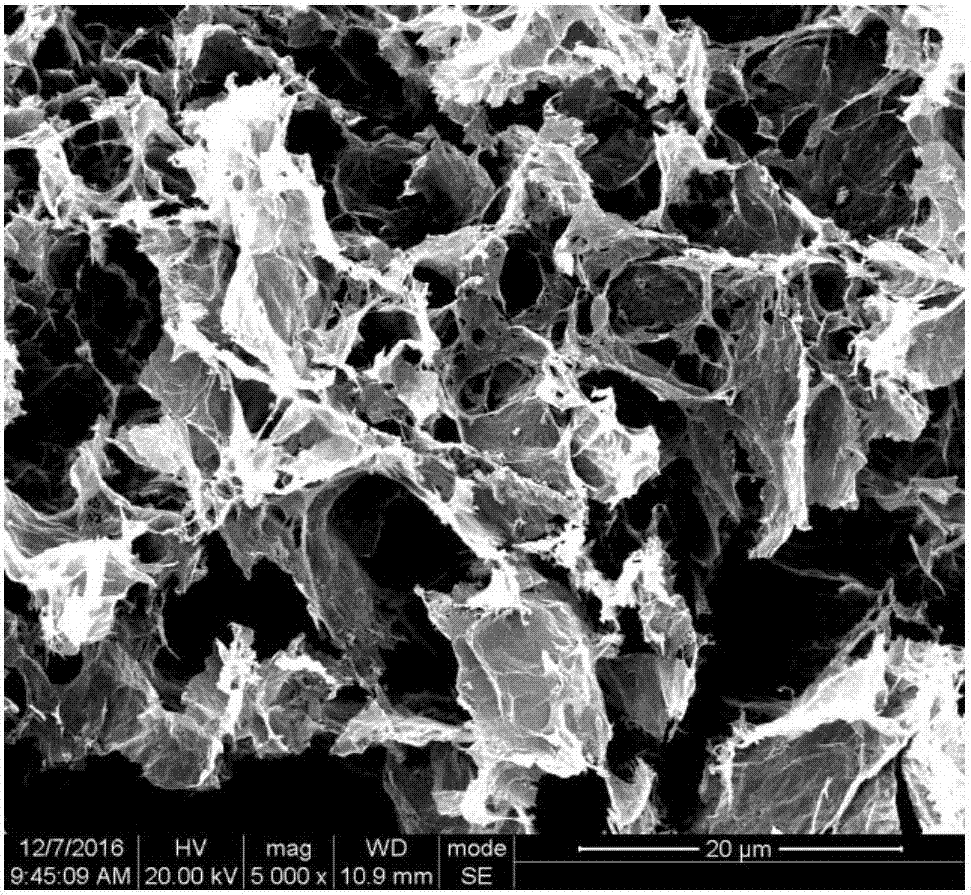

Image

Examples

preparation example Construction

[0035] A method for preparing a three-dimensional porous structure silicon / graphene composite negative electrode material described in the application comprises the following steps:

[0036] (1) Under the condition of 20-30°C, uniformly disperse the nano-silicon in the mixed solution of ethanol and water by electromagnetic stirring to obtain solution A; wherein, the time of the electromagnetic stirring is 10-60min, and the nano-silicon The particle size is 1-150nm, and the volume ratio of ethanol and water is 1: (1-100);

[0037](2) Add carboxymethyl cellulose and organic carbon source to the solution A described in step (1), mix well to obtain solution B, adjust the pH value to the solution B is alkaline; wherein, carboxymethyl cellulose The mass ratio of nano-silicon in solution A is (0.01-1): 1, and the organic carbon source is selected from at least one of phenolic resin, polypyrrole, polyvinyl alcohol, glucose, and sucrose;

[0038] (3) Mix alkaline solution B and graphe...

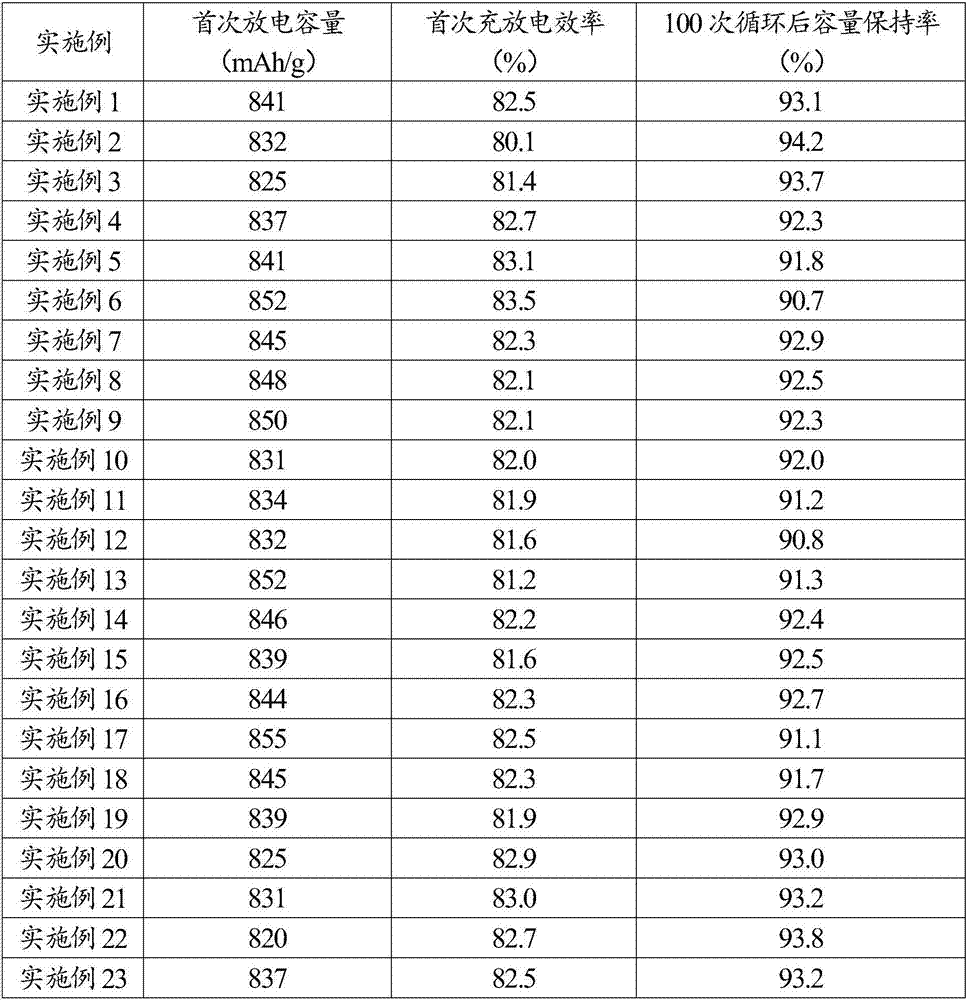

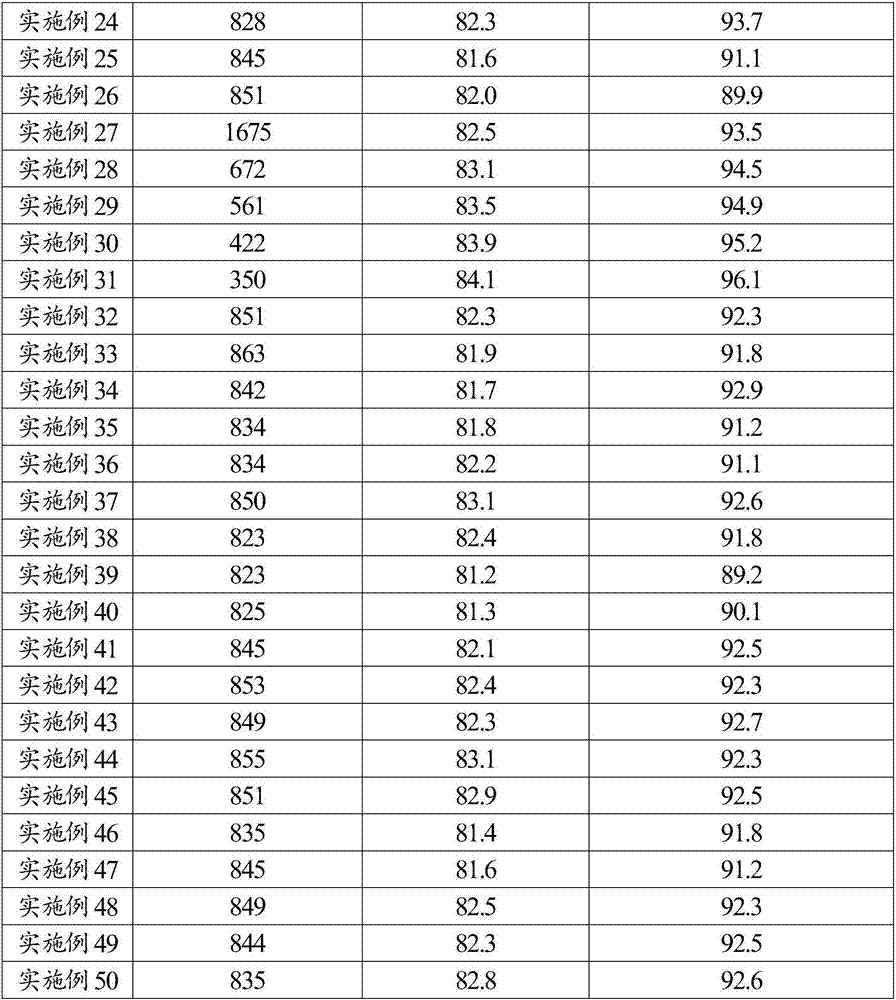

Embodiment 1

[0043] The preparation method of a kind of three-dimensional porous structure silicon / graphene composite negative electrode material described in this embodiment comprises the following steps:

[0044] (1) At room temperature, 200 mg of nano-silicon with a particle size of 20 nm was dispersed in a mixed solution of 30 mL of ethanol and water, wherein the volume ratio of ethanol: water was 1:1.5, and after electromagnetic stirring for 20 min, solution A was obtained;

[0045] (2) 35mg carboxymethylcellulose and 40mg polyvinyl alcohol were added to solution A at the same time, and the pH value was adjusted to 7.5 to obtain solution B;

[0046] (3) Add 100 mg of graphene oxide solution with a concentration of 4 mg / mL to solution B, ultrasonically disperse for 1 h, and then electromagnetically stir at 30° C. for 24 h to obtain solution C;

[0047] (4) Place solution C in liquid nitrogen and freeze for 30 minutes, then put it into a freeze dryer for freeze-drying treatment for 60 h...

Embodiment 2~ Embodiment 6

[0051] A method for preparing a three-dimensional porous structure silicon / graphene composite negative electrode material described in Examples 2 to 6 differs from Example 1 in that the particle diameters of step (1) nano-silicon are 1nm, 15nm, and 30nm , 50nm, 100nm, 150nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com