Adhesive-free packaged photovoltaic module

A photovoltaic module, glue-free packaging technology, applied in the field of solar power generation systems, can solve problems such as affecting installation efficiency, increasing power generation costs, packaging and sealing failure, saving materials and labor costs, improving power generation efficiency and avoiding sealing failure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

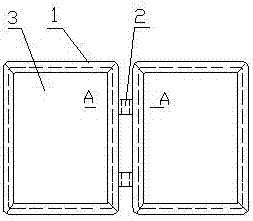

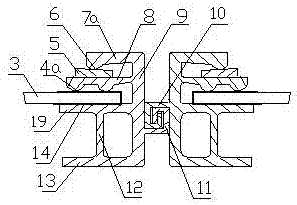

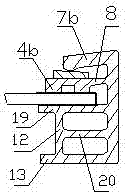

[0015] exist figure 1 , figure 2 , image 3 and Figure 4 Among them, the glue-free packaged photovoltaic module is a monomer, and the monomers are connected to each other and installed on the frame at a certain angle, which includes a laminate 3 and a frame 1, and the laminate includes battery sheets 17 and a glass plate 16 and a back plate 18 connected by EVA film 15 on both sides of the battery sheet to form a whole, the frame body is made of aluminum alloy profile, and the edge and side of the laminate are provided with a hydrophobic film layer 14, the The hydrophobic film layer is formed on the surface of the fiber mesh with a mixed solution of tetraethyl orthosilicate and methyltrioxysilane (the mixing weight ratio is determined according to the process requirements). The coating adopts the solution gel method (extraction coating), Existing technologies such as powder thermal spraying (thermal coating) or vacuum magnetron cathode sputtering (vacuum coating); figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com