Strong-swirling mixing and backflow stable-burning incinerator for processing organic pollutant waste gas

A technology of organic pollutants and incinerators, applied in the field of incinerators, can solve the problems of low combustion intensity of incinerators, poor pyrolysis and combustion effects, and environmental pollution, etc., to overcome low combustion intensity, intensification of combustion and heat transfer processes and Optimization, good self-stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

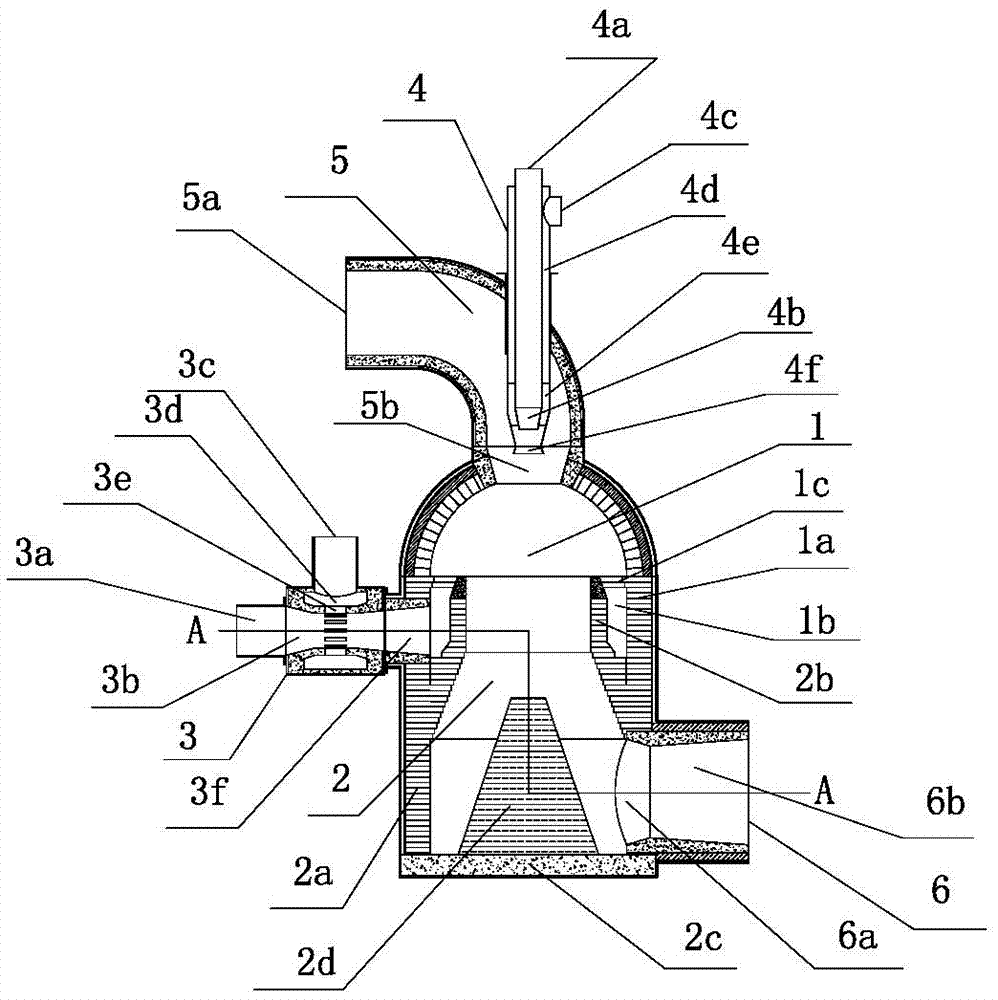

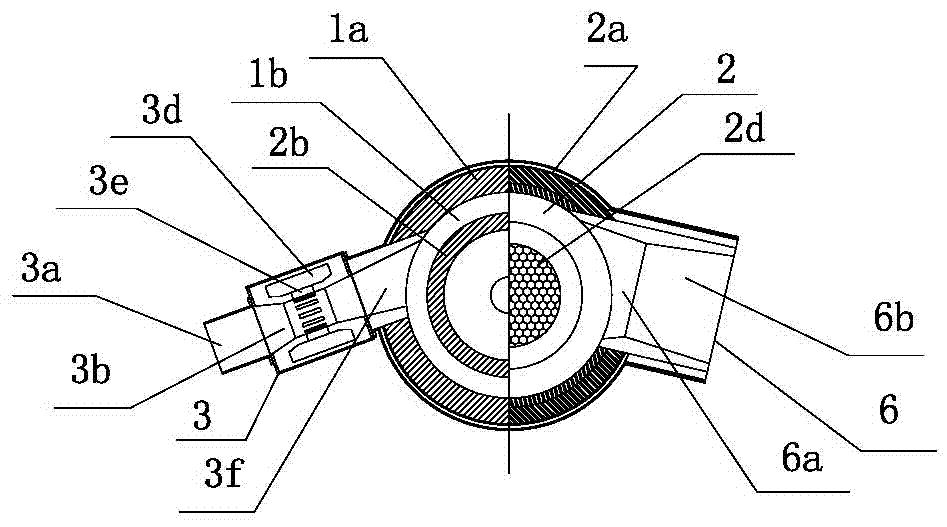

[0009] Depend on Figure 1-Figure 2 Given, the structure of the present invention is that the furnace body is a chamber structure composed of a refractory wall built in a metal furnace shell. The chamber in the furnace body is composed of a combustion mixing chamber 1 and a flue gas mixing chamber 2 connected up and down. The top of the mixing chamber 1 is connected to the exhaust gas introduction pipe 5, and there is an auxiliary burner 4 in the center of the exhaust gas introduction pipe. There is a mixed flue gas exhaust pipe 6 extending horizontally and obliquely out of the furnace body. The combustion mixing chamber 1 is a bell-shaped chamber with a lower opening formed by connecting the upper hemispherical vault and the lower cylinder body up and down. The wall of the combustion mixing chamber is the wall 1a of the combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com