Mining energy-saving emulsion pump station and control method thereof

An emulsion pumping station and emulsion pump technology, which is applied to the mining energy-saving emulsion pumping station and its control field, can solve the problems of low load of the hydraulic conveying system, low efficiency of the power supply system, increased mechanical loss, etc., and reduce the maintenance amount. , Save parts investment, reduce the effect of friction and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

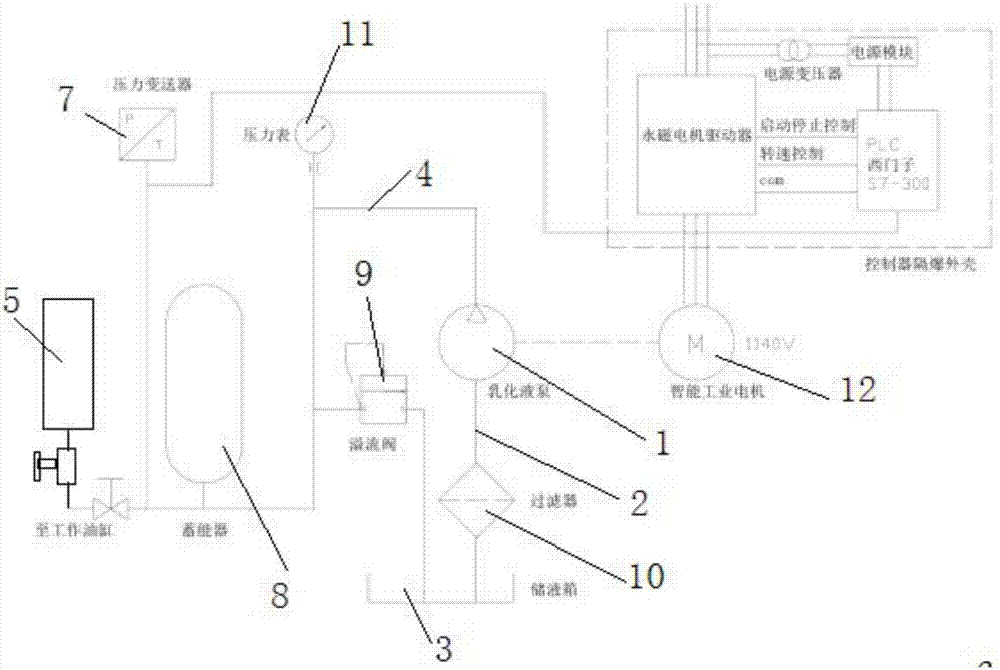

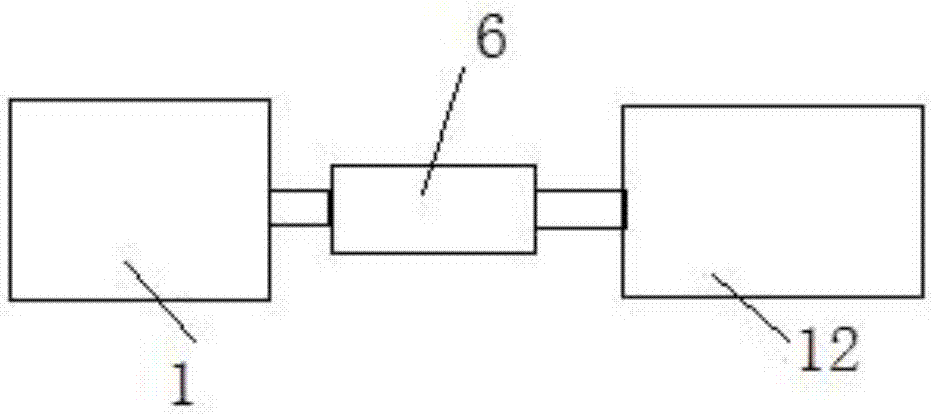

[0034] Embodiment 1: as Figure 1-Figure 3 As shown, a mining energy-saving emulsion pump station includes an emulsion pump 1, the inlet pipe 2 of the emulsion pump 1 is connected to the liquid storage tank 3, and its outlet pipe 4 is connected to the driving cylinder 5 of the multi-row hydraulic support , the driving end of the emulsion pump 1 is connected to the variable frequency intelligent industrial motor 12 through the coupling 6, and the hydraulic sensor 7 is connected to the liquid outlet pipe 4. The intelligent industrial motor adopts Jiaxuan JXSB series intelligent industrial motor, and the JXSB series intelligent industrial motor adopts The most advanced is the rare earth permanent magnet technology, which has the characteristics of small size, high efficiency, high power factor, large starting torque, good force index, and low temperature rise. Keep the pressure constant so that the hydraulic pump can run in the best energy-saving state. At the same time, the powe...

Embodiment 2

[0045] Embodiment 2: a kind of control method of mining energy-saving emulsion pump station, the method steps are as follows:

[0046] (1) Multiple hydraulic supports are installed on the well entry face;

[0047] (2) Connect each driving cylinder of the hydraulic support to the liquid outlet of the emulsion pump station, and the liquid outlet is equipped with an electro-hydraulic master switch;

[0048] (3) Start the intelligent industrial motor, set the operating frequency at 55kHz, the emulsion pump starts to operate, and the accumulator stores energy. When the pressure detected by the hydraulic sensor reaches 30MPa, turn on the main electro-hydraulic switch, and use the respective hydraulic brackets to store energy. The electro-hydraulic switch driving the oil cylinder controls the six hydraulic supports to realize the support of the hydraulic supports;

[0049] (4) When the hydraulic sensor detects that the pressure is lower than 22MPa, the controller controls the intell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com