Tailing liquification floating collecting device

A technology of collection device and liquefaction device, applied in safety devices, mining equipment, earth-moving drilling, etc., can solve the problems of submersible pump motor burnout, uneven concentration of tailings slurry, insufficient material supply, etc., so as to eliminate the large fluctuation of tailings concentration. , High tailings liquefaction efficiency and the effect of reducing construction water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

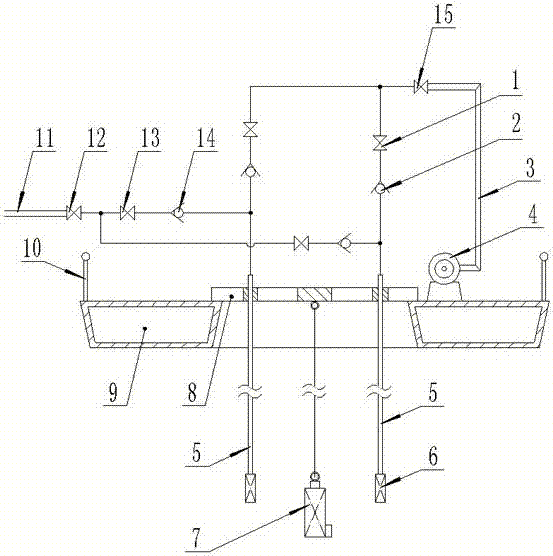

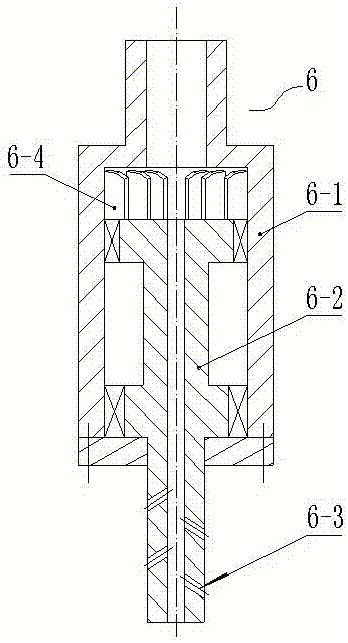

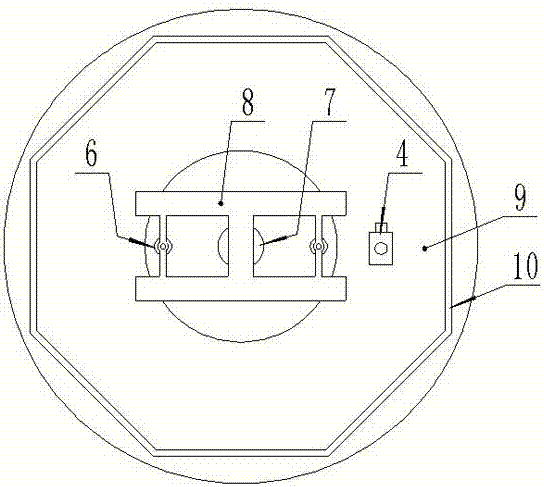

[0015] Such as figure 1 , image 3 Shown: the installation frame 8 is fixed on the circular floating platform 9, and the submersible pump 7 is hoisted below the floating platform by a steel rope (not shown in the figure) fixed on the installation frame 8; around the submersible pump 7 There are two sets of sand stirring and liquefaction devices distributed. The sand-stirring liquefaction device is composed of a spray pipe 5 fixed on a mounting frame 8 and a liquefaction agitation nozzle 6 fixed at the lower port of the spray pipe. Each injection pipe 5 passes through the water supply branch pipe (not shown in the figure) with the water supply check valve 14 and the air supply branch pipe (not shown in the figure) with the air supply check valve 2 respectively, corresponding to the water supply main pipe 11, The air supply main pipe 3 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com