Heat insulation skeleton, heat insulation framework, heat insulation wall and construction method

A technology for thermal insulation of walls and skeletons, applied to walls, building materials, building components, etc., can solve problems such as fire prevention, poor durability, lack of heat storage function, and low service life, and achieve short construction periods, water saving and Artificial, monolithic light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be described below according to the embodiments shown in the accompanying drawings. It can be thought that embodiment disclosed this time is an illustration in every point, and is not restrictive. The scope of the present invention is not limited by the description of the following embodiments but only by the scope of the claims, and includes the same meaning as the scope of the claims and all modifications within the scope of the claims.

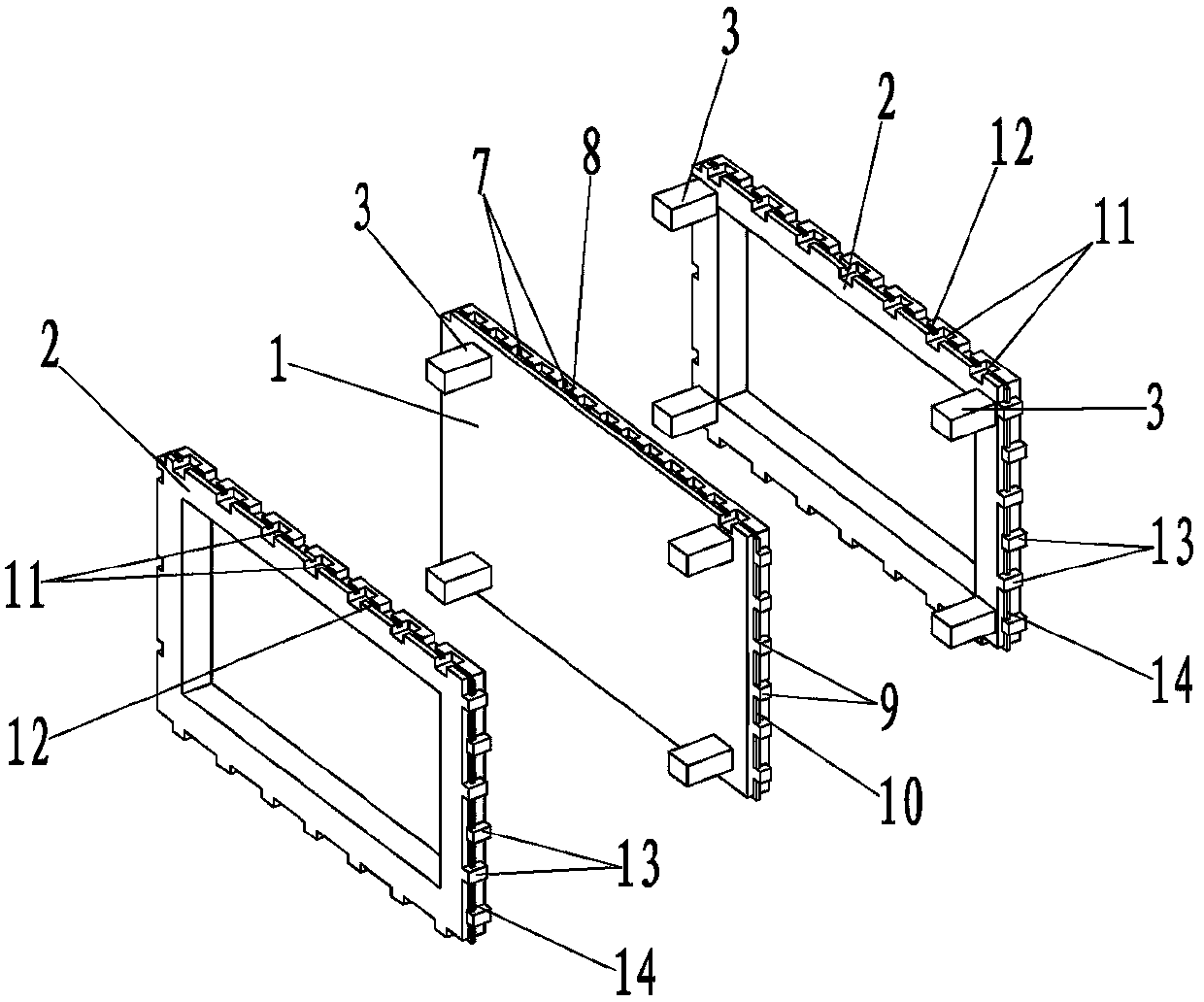

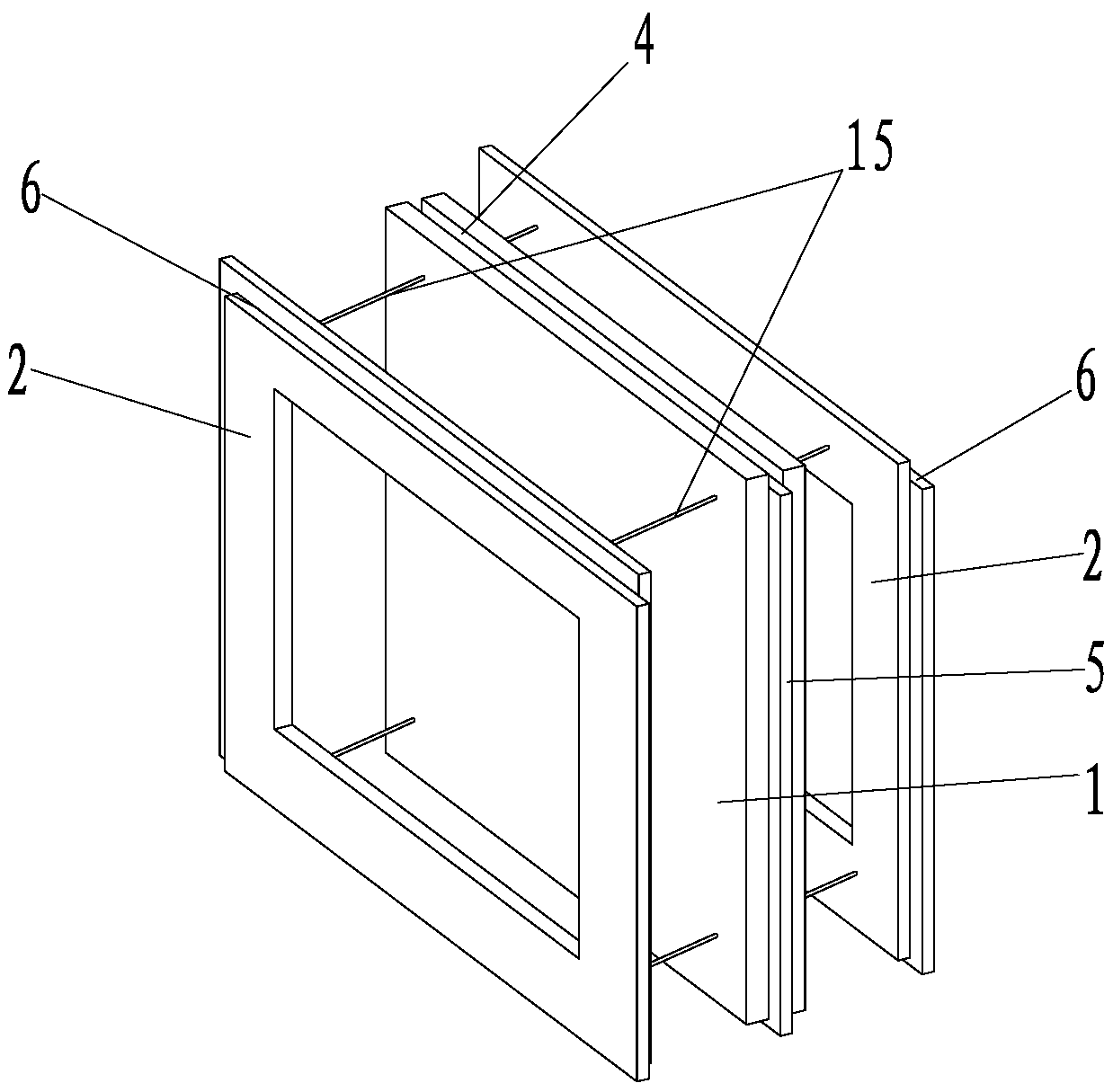

[0079] The following describes the thermal insulation framework and the thermal insulation wall involved in the present invention in detail in conjunction with the accompanying drawings.

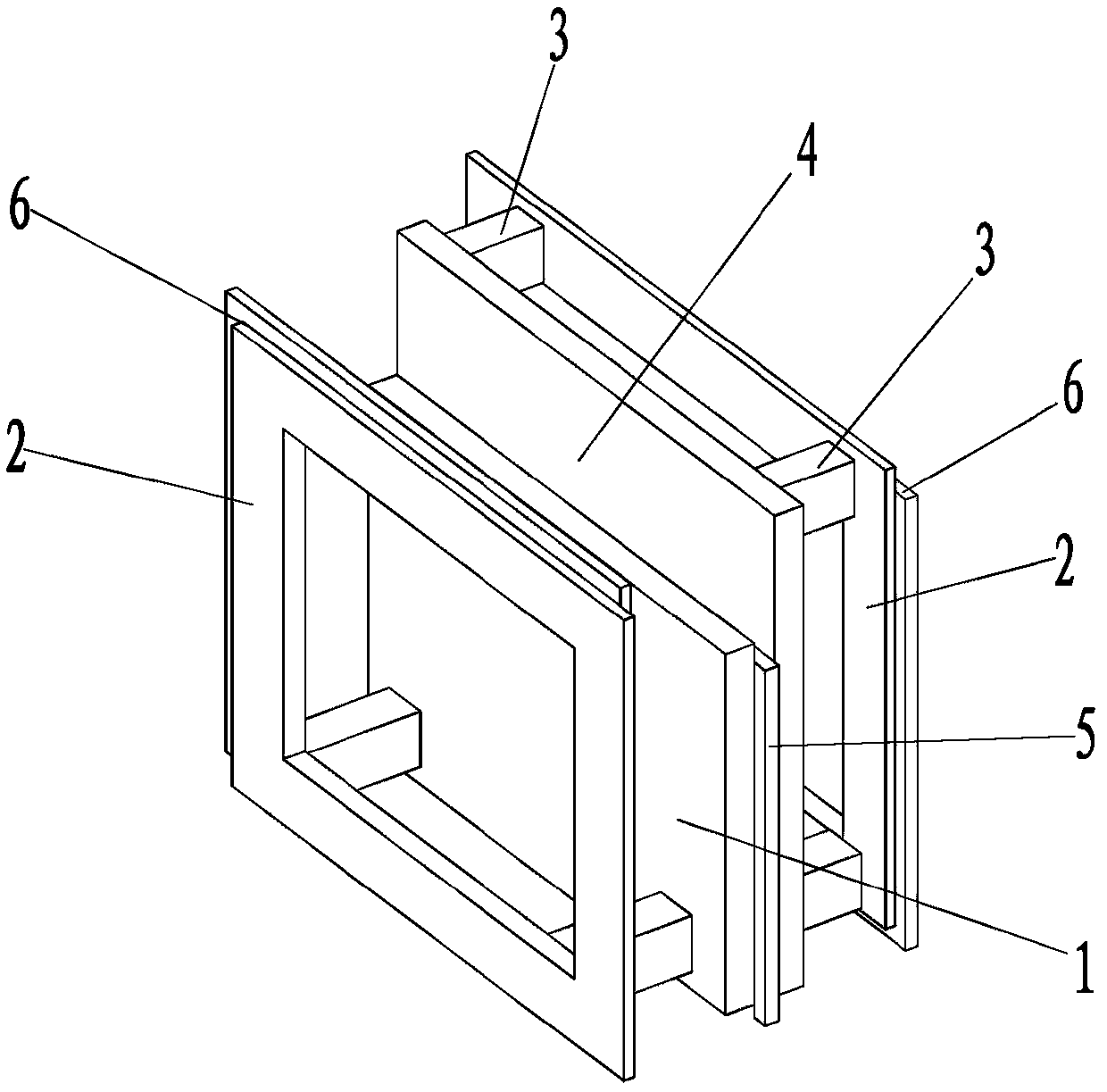

[0080] Such as figure 1 The structure diagram of Embodiment 1 of the thermal insulation framework of the present invention is shown, including a thermal insulation board 1 made of thermal insulation material, and one or both sides of the thermal insulation board 1 pass through at least one connecting block or at least on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com