Novel ablation heat-resistant coating and preparation method thereof

A technology of heat-resistant coatings and raw materials, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of insufficient thermal protection of high-performance tactical missiles, and achieve the effects of excellent comprehensive performance, low thermal conductivity and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

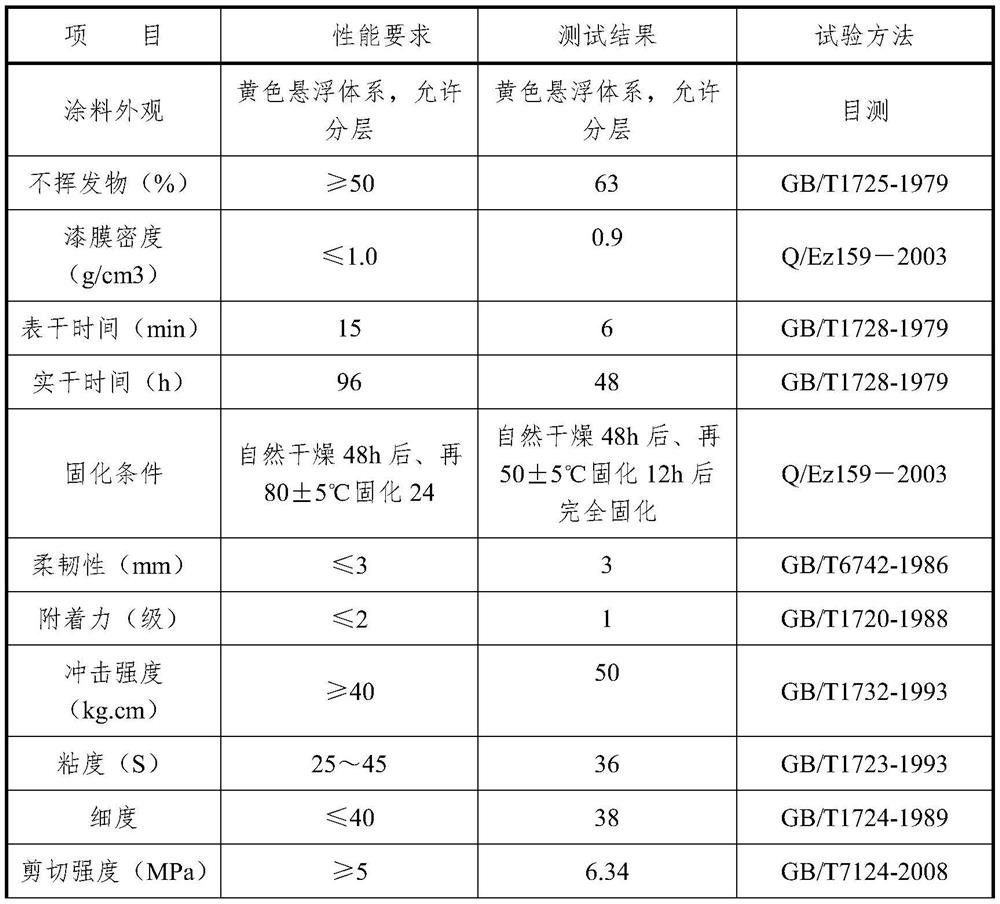

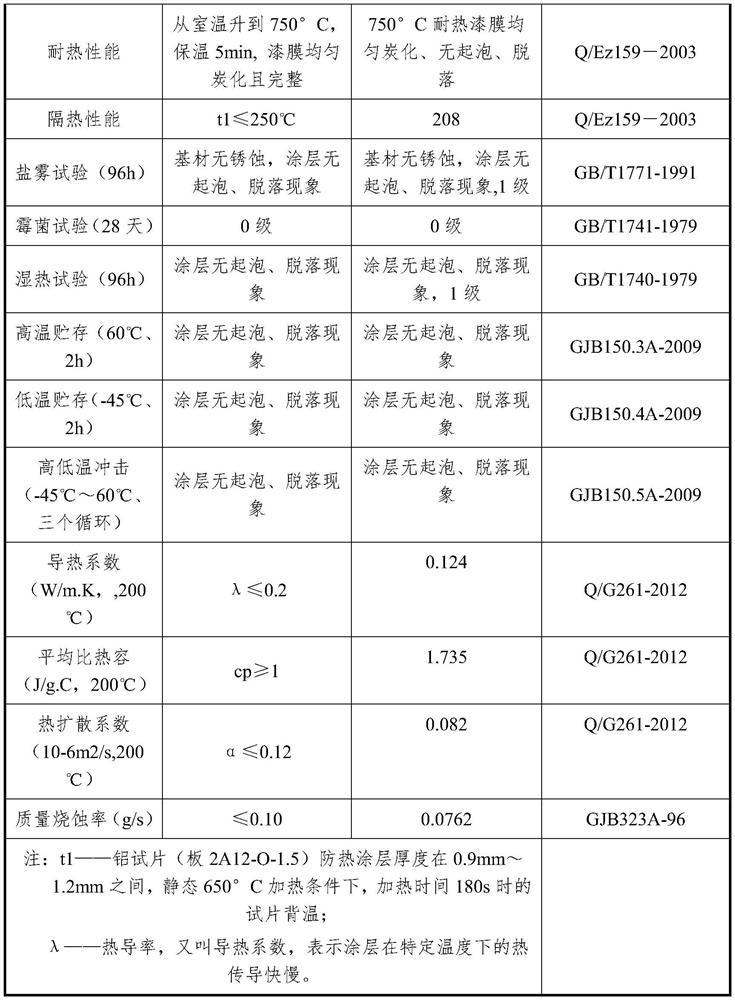

Examples

Embodiment 1

[0029] Formula: Component A: 16kg of silicone resin, 8kg of phenolic epoxy resin, 8kg of fumed nano-silica, 20kg of low-density and low-conductivity filler, 25kg of additives; Component B: the mass of imidazole is 2% of that of Component A.

[0030] Preparation method: (1) Premixing: Measure silicone resin, phenolic epoxy resin, fumed nano-silica, low-density and low-conductivity filler and additives according to the formula, and stir evenly with a nylon rod to obtain a mixture;

[0031] (2) Dispersion: Add the pre-mixed mixture into the disperser, disperse at a speed of 800r / min for 50min, and then disperse at a speed of 1000r / min for 100min at a high speed to obtain a dispersion;

[0032] (3) Sand milling: Put the dispersed material into the sand mill, and use glass beads or zirconia beads of φ1.5~φ3 as the sanding medium. During the sanding process, the viscosity of the material is controlled to be 25s, and the particle size is ≤40μm. can;

[0033] (4) Filtration: Filter t...

Embodiment 2

[0042] Formula: A component: silicone resin 32kg, phenolic epoxy resin 16kg, fumed nano silica 12kg, low density and low conductivity filler 30kg, imidazole curing agent 3kg, auxiliary agent 30kg; B component: 2-methylimidazole The mass is 3% of A component.

[0043] Preparation method: (1) Premixing: Measure silicone resin, phenolic epoxy resin, fumed nano-silica, low-density and low-conductivity filler and additives according to the formula, and stir evenly with a nylon rod to obtain a mixture;

[0044] (2) Dispersion: Add the pre-mixed mixture into the disperser, disperse at a speed of 1000r / min for 60min, and then disperse at a high speed of 1200r / min for 120min to obtain a dispersion;

[0045] (3) Sand milling: Put the dispersed material into the sand mill, and use glass beads or zirconia beads of φ1.5~φ3 as the sanding medium. During the sanding process, the viscosity of the material is controlled to be 45s, and the particle size is ≤40μm. can;

[0046] (4) Filtration:...

Embodiment 3

[0055] Formula: Component A: 22kg of silicone resin, 10kg of phenolic epoxy resin, 9kg of fumed nano-silica, 23kg of low-density and low-conductivity filler, 2kg of imidazole curing agent, 27kg of additives; Component B: 2-ethylimidazole The mass of A component is 2.5%.

[0056] Preparation method: (1) Premixing: Measure silicone resin, phenolic epoxy resin, fumed nano-silica, low-density and low-conductivity filler and additives according to the formula, and stir evenly with a nylon rod to obtain a mixture;

[0057] (2) Dispersion: Add the pre-mixed mixture into the disperser, disperse at a speed of 800r / min for 60min, and then disperse at a speed of 1000r / min for 120min at a high speed to obtain a dispersion;

[0058] (3) Sand milling: Put the dispersed material into the sand mill, and use glass beads or zirconia beads of φ1.5~φ3 as the sanding medium. During the sanding process, the viscosity of the material is controlled to be 35s, and the particle size is ≤40μm. can;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com