Electrolyte used for lithium-sulfur battery and preparation method of electrolyte

A lithium-sulfur battery and electrolyte technology, applied in the field of electrochemistry, can solve the problems of the influence of cycle efficiency battery cycle life, limited lithium-sulfur battery cycle life, low lithium cycle efficiency, etc., to achieve excellent electrochemical performance, no self-discharge, Superior magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

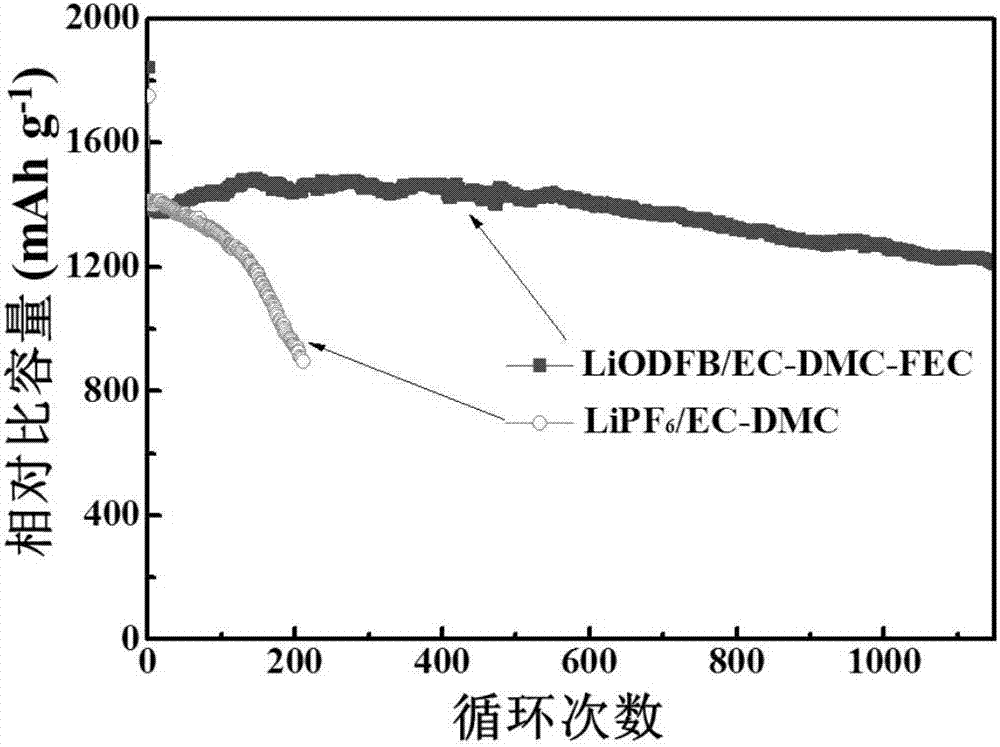

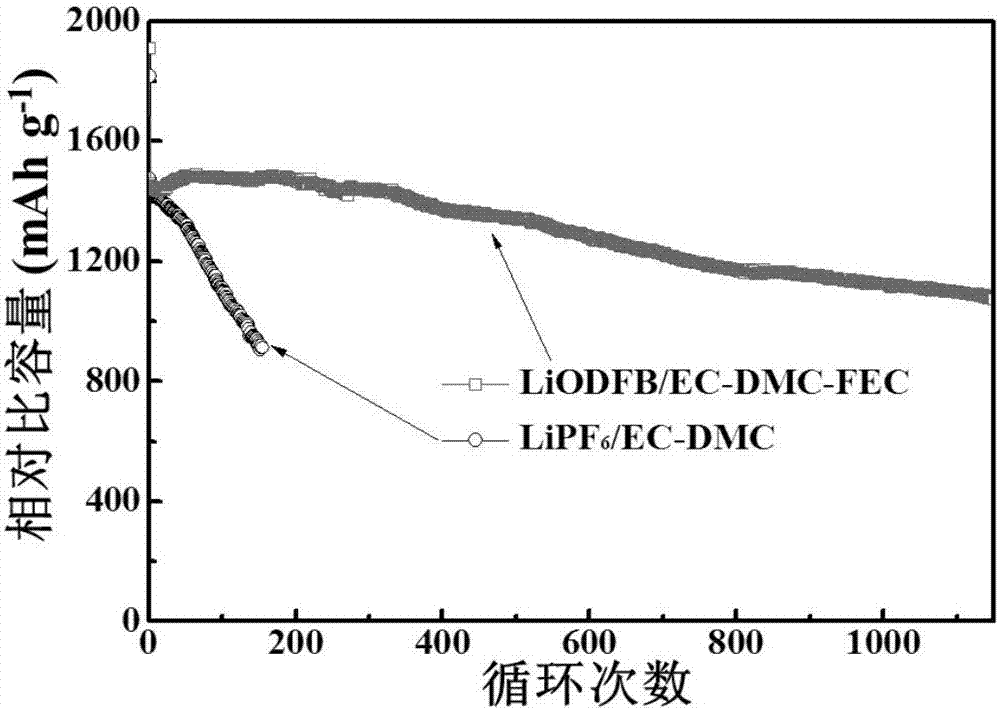

Embodiment 1

[0024] Mix EC, DMC, and FEC evenly in a glove box at a volume ratio of 4.5:4.5:1, and stir for 30 minutes. Add LiODFB to the mixed solvent, stir to dissolve completely, and continue stirring for 12 hours to make a 1.0mol / L electrolyte. The room temperature ionic conductivity of the electrolyte obtained in the present embodiment is 7.2mS / cm; the cyclic voltammogram of the electrolyte obtained in the present embodiment is as follows figure 1 As shown, a platinum disk electrode with a diameter of 2mm was used as the working electrode, and a lithium metal sheet was used as the counter electrode and reference electrode. The scanning speed was 5mV / s, and its electrochemical window was greater than 5.5V.

Embodiment 2

[0026] In the same way as in Example 1, 1mol / L LiODFB / EC-DMC-FEC (v:v:v=4:4:2) was prepared, and the room temperature ionic conductivity of the electrolyte prepared in this example was 7.1mS / cm; The electrochemical window of the electrolyte obtained in this embodiment is greater than 5.5V.

Embodiment 3

[0028] In the same way as described in Example 1, 1mol / L LiODFB / EC-DEC-FEC (v:v:v=4.5:4.5:1) was prepared, and the room temperature ionic conductivity of the electrolyte prepared in this example was 7.18mS / cm; The electrochemical window of the electrolyte obtained in this embodiment is greater than 5.5V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com