Method and system for representing numerical value of stress-strain constitutive relation of material

A technology of constitutive relationship and numerical characterization, applied in the direction of analyzing materials, using stable tension/pressure to test the strength of materials, measuring devices, etc., can solve problems such as large performance deviations and inability to meet design refinement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to the method of the present invention, materials with different properties are specifically measured, a numerical model is used to simulate them, the parameters in the model are calculated, and the mechanical properties of the measured material are obtained.

[0040] According to the classification of metal materials into materials with obvious yield stages and materials without obvious yield stages, the corresponding numerical model is selected. When the material is a material with obvious yield stages, the stress-strain numerical model corresponds to for,

[0041] Where T s It represents the lowest temperature at which the tensile curve yield platform disappears, and a and b are the parameters in the stress-strain numerical model. By calculating the parameters a and b, the mechanical properties of the material with an obvious yield stage can be characterized.

[0042] When the material has no obvious yield strength, the corresponding stress-strain numerical model...

Embodiment 2

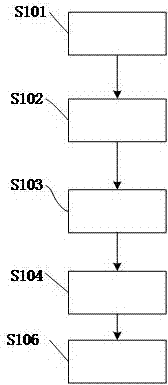

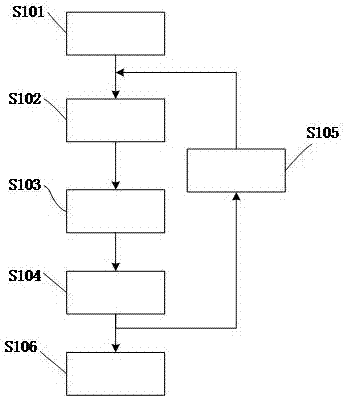

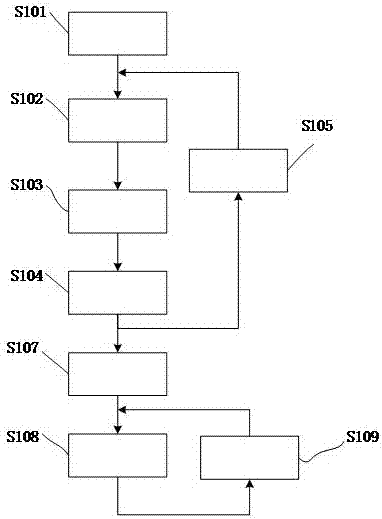

[0076] Such as figure 1 As shown, the numerical characterization method of the material stress-strain constitutive relationship in this embodiment of the present invention includes S101 setting test parameters, and the test parameters include sample temperature.

[0077] In S102, a tensile test is performed on the material according to the test parameters to obtain tensile test data of the material, where the tensile test data includes stress data and strain data.

[0078] S103 establishes a stress-strain curve according to the stress data and the strain data.

[0079] In S104, a corresponding stress-strain numerical model is selected according to the properties of the material, the stress-strain curve of the material is fitted, and the parameters in the stress-strain numerical model are obtained. The numerical characterization method in the embodiment of the present invention is close to reality. The stress and strain data of the tensile test are used as the fitting basis, and the n...

Embodiment 3

[0094] Such as Figure 5 As shown, an embodiment of the numerical characterization method of the material stress-strain constitutive relationship of the present invention adopts a tensile test to obtain the test data of the material, which specifically includes, S201 formulates the test method according to the material, and sets the sample of the material sample Require, set the strain rate, set the frequency of data resources, set the strain range, set the stretching rate, and set the temperature of the test. The sample used in this embodiment of the present invention is such as Image 6 As shown, the sample with a diameter of 10mm is selected, and the stretching is divided into room temperature stretching and high temperature stretching. The stretching rate is set in two cases. When stretching at room temperature, it is stretched at room temperature. The stretching temperature is 10℃~35℃, the stretching temperature can also be set to 23℃±5℃, and it can also be set at 20℃ for st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com