A kind of preparation method of polyester modified material and film product thereof

A polyester modification and polyester technology, applied in the field of fully biodegradable film products, can solve the problems of poor mechanical properties and barrier properties, difficult to control the degradation rate, and difficult large-scale production, etc., to increase surface smoothness, Solve the problem of interface compatibility and improve the effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

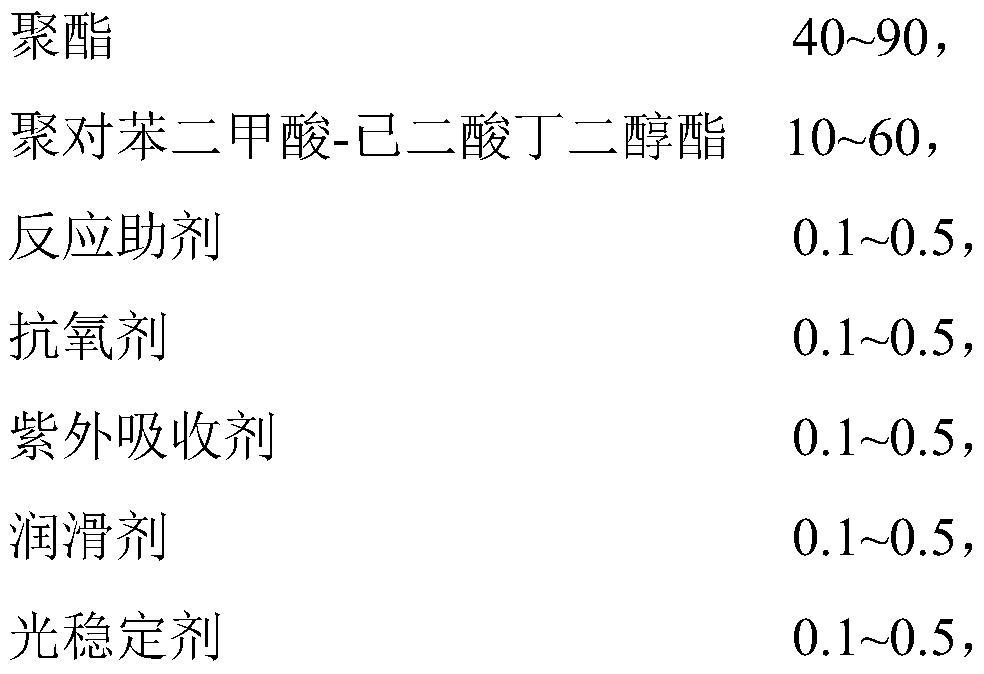

[0034] A polyester modified material, by weight, 87.5 parts of PGA (intrinsic viscosity is 1.2dl / g), 10 parts of PBAT (intrinsic viscosity is 1.0dl / g) are dried with 0.5 parts of reaction aid peroxide peroxide Dibenzoyl, 0.5 part of antioxidant 1076, 0.5 part of lubricant oleic acid amide, 0.5 part of ultraviolet absorber UV531, and 0.5 part of light stabilizer 622 were added to the high mixer and stirred for 30 minutes, and then the mixture was passed through The twin-screw extruder is melt-blended at a screw length-diameter ratio of 40:1, a rotational speed of 35 r / min, a plasticizing section temperature of 200 °C, a homogenization section temperature of 225 °C, an extrusion section temperature of 230 °C, and a die temperature of 225 °C. After reaction extrusion modification, the modified material was naturally cooled to room temperature, and the intrinsic viscosity was 1.1dl / g by sampling.

[0035] The PGA modified material with an intrinsic viscosity of 1.1dl / g was blown w...

Embodiment 2

[0037]A polyester modified material, by weight, 40 parts of PGA (intrinsic viscosity is 3.0dl / g), 59.5 parts of PBAT (intrinsic viscosity is 2.9dl / g) are dried with 0.1 part of the reaction assistant peroxide peroxide Cumene, 0.1 part of antioxidant BHT, 0.1 part of lubricant zinc stearate, 0.1 part of ultraviolet absorber UV320, 0.1 part of light stabilizer 770 were added to the high mixer, stirred and mixed for 30min, and then the mixture was passed through The twin-screw extruder is melt-blended at a screw length-diameter ratio of 18:1, a rotational speed of 17 r / min, a plasticizing section temperature of 165 °C, a homogenization section temperature of 180 °C, an extrusion section temperature of 185 °C, and a die temperature of 180 °C. After reaction extrusion modification, the modified material was naturally cooled to normal temperature, and the intrinsic viscosity was 3.0dl / g by sampling.

[0038] The PGA modified material with an intrinsic viscosity of 3.0dl / g was blown ...

Embodiment 3

[0040] A polyester modified material, by weight, 65 parts of PGA (intrinsic viscosity is 2.3dl / g), 33.5 parts of PBAT (intrinsic viscosity is 2.1dl / g) are dried with 0.3 parts of reaction aid peroxyacetic acid Tert-amyl ester, 0.3 part of antioxidant 168, 0.3 part of lubricant calcium stearate, 0.1 part of ultraviolet absorber UV326, 0.2 part of ultraviolet absorber UV-P, 0.3 part of light stabilizer 783 were added to high-mix The machine was stirred and mixed for 30 minutes, and then the mixture was passed through a twin-screw extruder at a screw length-diameter ratio of 30:1, a rotational speed of 25 r / min, a temperature of 190 °C in the plasticizing section, 210 °C in the homogenization section, and 220 °C in the extrusion section. , The temperature of the die head is 210 ℃, the temperature of the die head is 210 ℃, and the extrusion modification is melted and blended. After the modified material is naturally cooled to room temperature, the intrinsic viscosity is 2.2 dl / g by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com