Machine tool for processing horseshoe-shaped slots of drill bit

A horseshoe-shaped and drill bit technology, which is applied in the field of machine tools for processing drill bit horseshoe-shaped grooves, can solve the problems of drilled holes not straight, drill bit axis bending, deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

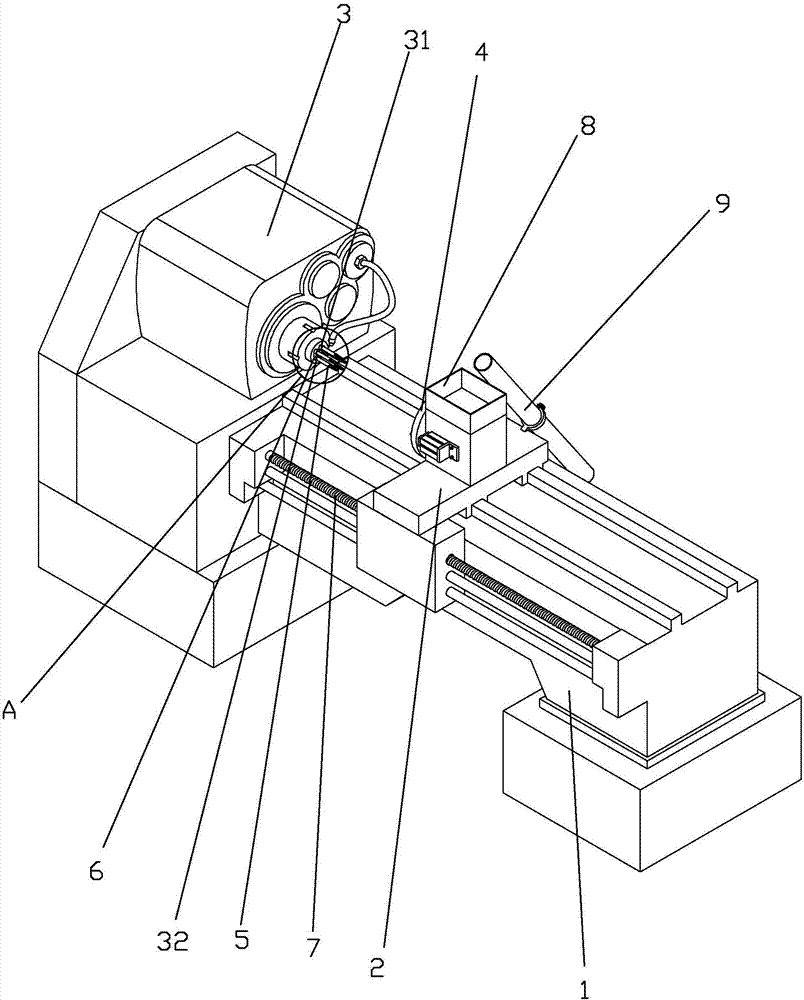

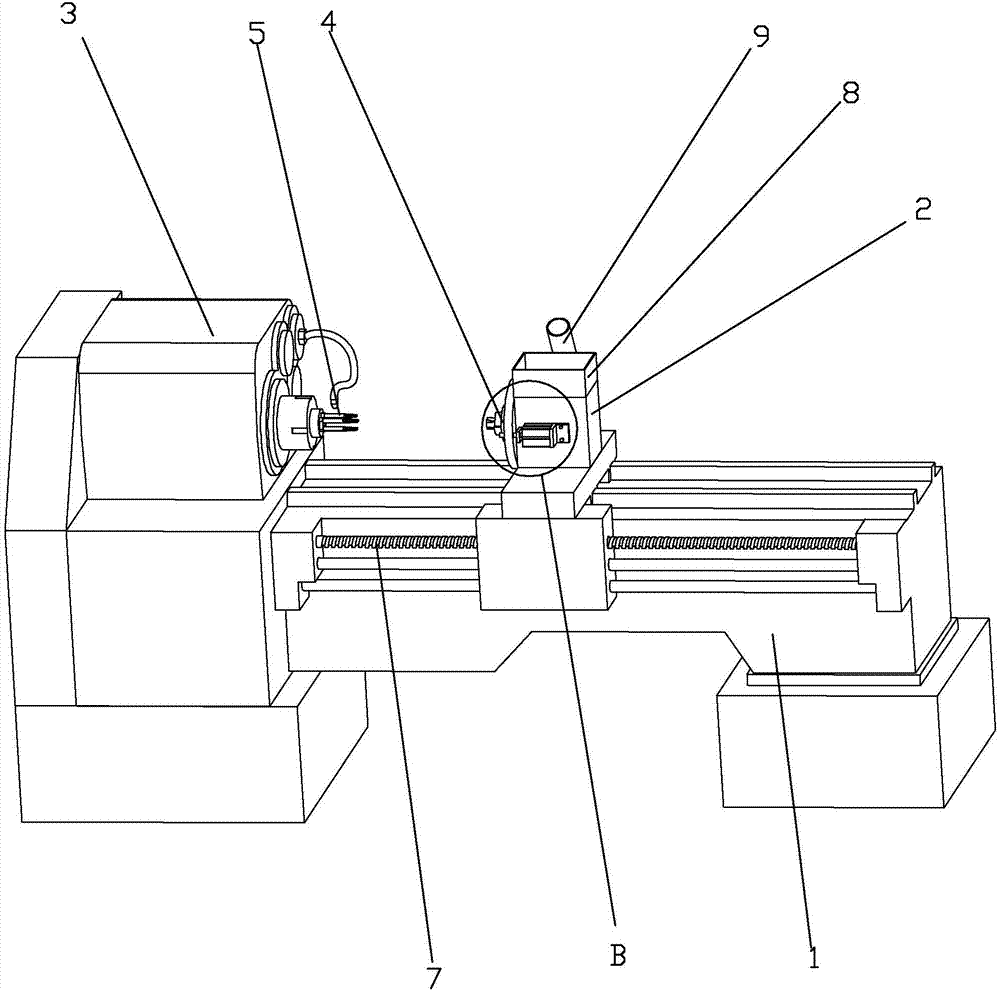

[0037] Embodiment 1: as figure 1 , figure 2 with image 3 As shown, a machine tool for processing drill bit horseshoe-shaped grooves, including a frame 1, a power head 3 is provided at one end of the frame 1, and a first power output portion 32 is provided on the side of the power head 3 facing the middle of the frame 1, The power head 3 is provided with a power source, and the power source is generally a motor, and the first power output part 32 and the motor are shifted through gears. The conical milling cutter 5 that is used for milling is fixed on the power output part 31, is also provided with 4 power output parts 31 on the same side of the first power output part 32 outer power head 3, is all fixed with conical milling cutter 5 on the power output part 31. The milling cutter 5 has the same taper as the angle of inclination of the horseshoe-shaped groove 16. All the power output parts 31 are evenly distributed along the circumference and correspond to the positions of...

Embodiment 2

[0042] Embodiment 2: as Figure 7 , Figure 8 with Figure 9 As shown, the difference between embodiment 2 and embodiment 1 is that the fixing base 2 is fixed in the middle of the frame 1, and the power heads 3 are arranged on both sides of the fixing base 2. Both sides of the fixed base 2 facing the power head 3 are provided with pneumatic chucks 4 for clamping the drill bit 15; at the same time, the two power heads 3 are provided with four power output parts 31, which can have four horseshoe-shaped grooves. The drill bit 15 of 16 is processed. Starting from the first power output portion 32 , the other power output portions 31 are named as the second power output portion 31 , the third power output portion 31 and the fourth power output portion 31 in the counterclockwise direction. The first power output part 32 and the third power output part 31 interfere with the inner ring of the belt 6, and the second power output part 31 and the fourth power output part 31 interfere ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com