Numerical control intelligent shell peeling machine

A technology of intelligent shelling machine and frame, which is applied in the fields of cleaning, CNC intelligent shelling machine, and automatic shelling of boiled poultry eggs during processing, which can solve the problems affecting cost and sales, high scrap rate, and more egg white damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

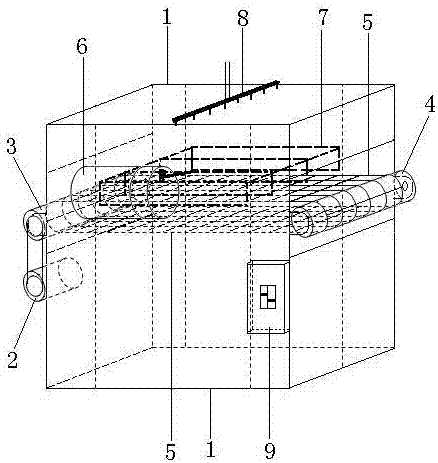

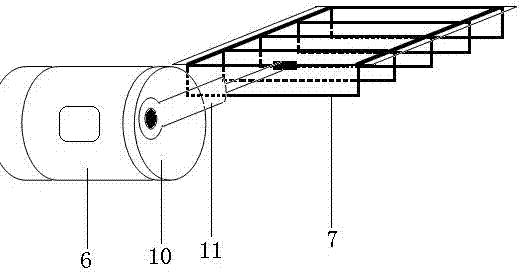

[0011] The purpose of the present invention is further described now in conjunction with accompanying drawing:

[0012] CNC intelligent peeling machine: including frame 1, speed regulating motor 2, driving roller 3, expansion roller 4, mesh conveyor belt 5, crushing push plate motor 6, crushing push plate 7, porous nozzle 8, control box 9, crank 10. The connecting rod 11, the speed regulating motor, the driving roller, the tensioning roller, the crushing push plate motor, the crushing push plate 7, the porous nozzle and the control box are installed on the frame, and the speed regulating motor is connected with the driving roller through the transmission belt. The driving roller is connected to the tensioning roller through a mesh conveyor belt, the motor of the crushing push plate is connected to the crank through its own central axis, the crushing push plate is connected to the connecting rod, the connecting rod is connected to the crank, the porous nozzle is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com