Drum-type mulch puncture and under-mulch precision seeder

A drum-type, seeder technology, applied in the direction of sowing, sowing seeders, seeder parts, etc., can solve the problem of seeds falling outside the hole or even throwing on the film, the timing of opening the mouth, the size is not uniform, and the influence of height difference is relatively large. Large and other problems, to achieve the effect of increased seeding speed, stable mulch, and small puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

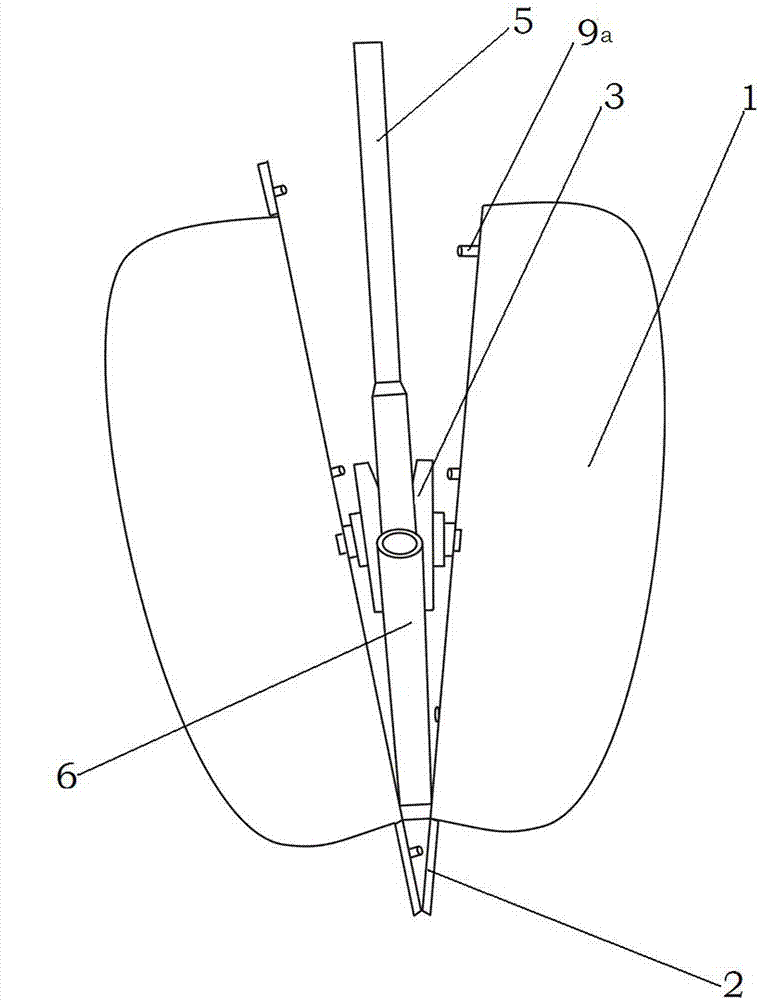

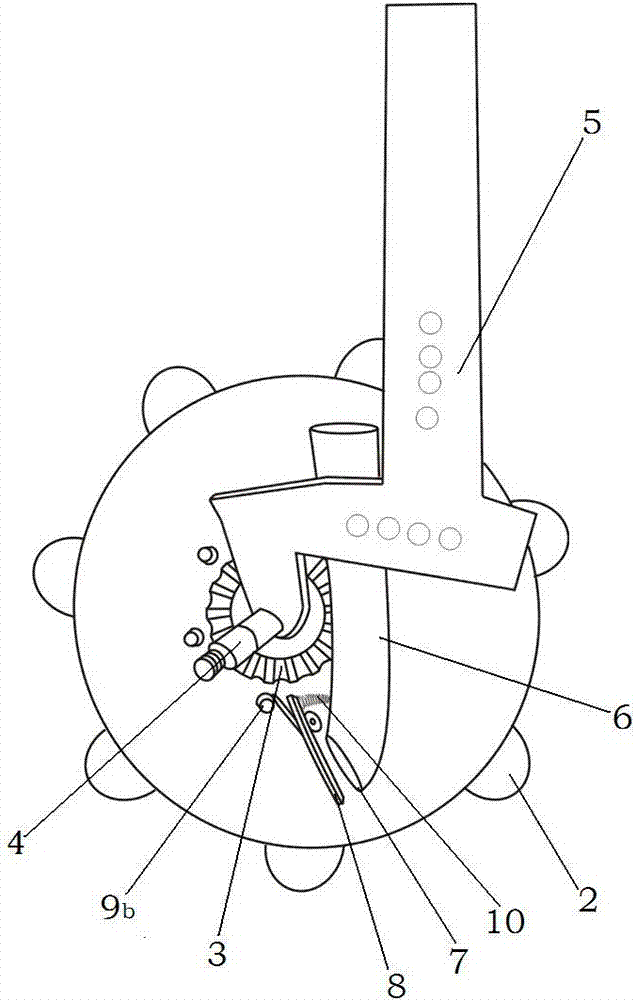

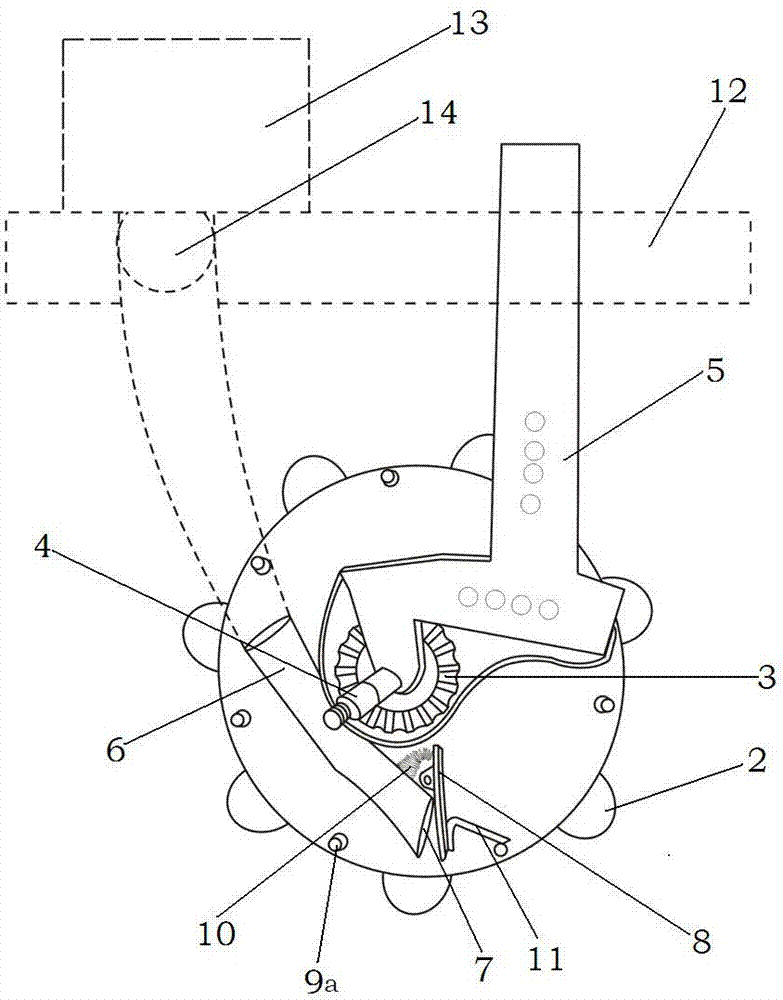

[0014] refer to figure 1 , figure 2 , the seeder of the present invention comprises: two cylinders 1 that the left and right opposite ends are arranged symmetrically in a V shape, the thorn membranes distributed on the circumference of each cylinder at the opposite ends of the two cylinders and the teeth 2 that squeeze and dig the seed holes are respectively fixed on two A pair of bevel gears 3 at opposite ends of the rollers, constraining the synchronous rotation of the two rollers, respectively supporting the two roller shafts 4 of the two rollers, fixing the roller shafts and connecting the sower drawbar of the tractor (or tractor-drawn seeder frame) 5. The seed introduction pipe 6 of the intermittent seed metering device fixed on the drawbar and connected to the frame, the seed introduction pipe extends to the slightly inclined lateral seed drop opening 7 on the ground directly below the drum, and is hinged on the seed guide Control the opening and closing of the seeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com