Method applicable to simultaneous and rapid determination of organic phosphate fire retardants (OPFRs) in different food sample matrixes

A detection method and food technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problem of no OPFRs application research report, etc., and achieve the effects of high selectivity and sensitivity, shortened analysis time, and fast analysis speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

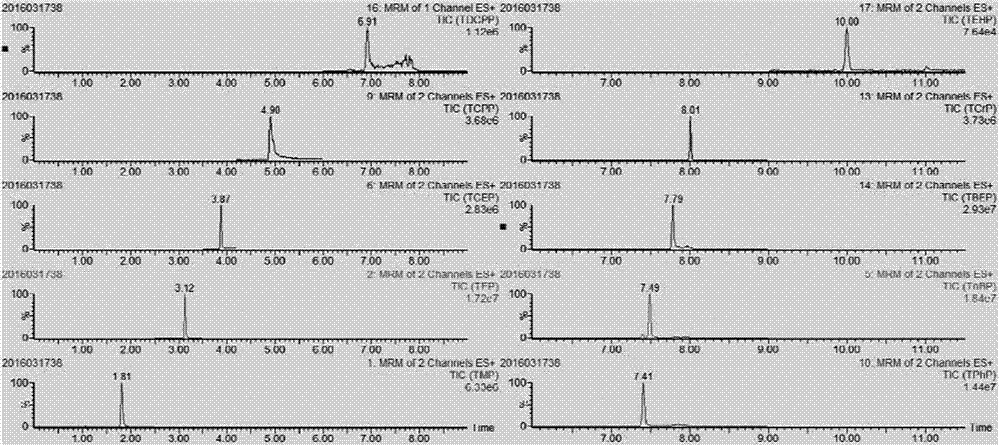

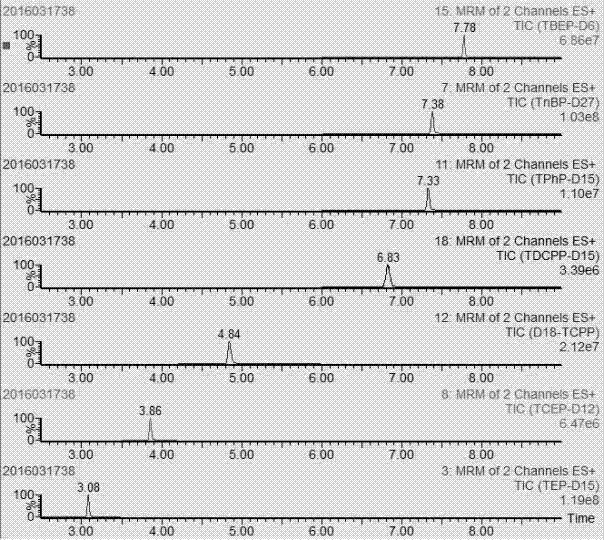

Image

Examples

Embodiment 1

[0067] This embodiment focuses on the matrix effect of the analytical method, the recovery rate of standard addition and the production of a standard working curve.

[0068] Step (1): Mixed sample processing

[0069] Take the same amount of fish, chicken, pork, vegetables, and milk, each 10 g, mix and homogenize fully;

[0070] Step (2): Extract

[0071] Accurately weigh 1.0 g of the homogenate into 10 ml stoppered glass centrifuge tubes, numbered A1-A7, B1-B7 respectively, and add 50 μL of different concentrations (1, 5, 10, 50, 100, 500, 1000 ng ml -1 ) standard substance mixed solution and 20 μL internal standard mixed solution (1000 ng·ml -1 ), A1-A7 and B1-B7 were added with 4 ml 0.5% formic acid-acetonitrile, vortexed for 1 min, and ultrasonically extracted for 10-15 min. Take another 10 ml centrifuge tube, numbered C1-C7, add 4 ml of acetonitrile containing 0.5% formic acid, vortex mix for 1 min, and ultrasonically extract for 10-15 min.

[0072] Step (3): Purifica...

Embodiment 2

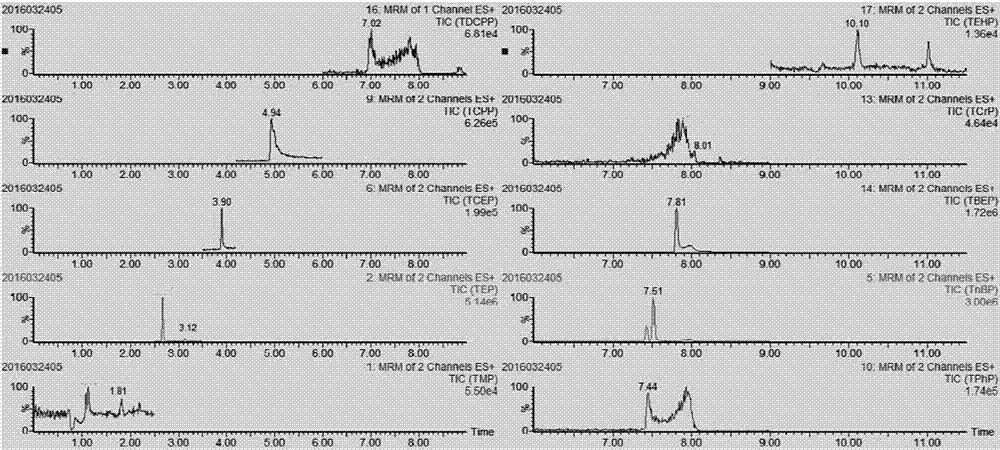

[0092] This example is the application of the present invention to the detection of OPFRs in chicken meat.

[0093] Step (1): Chicken sample processing

[0094] Take 5 g of washed chicken breast, and fully homogenize;

[0095] Step (2): Extract

[0096] Accurately weigh 1.0 g of chicken homogenate in 3 parts, respectively, into 10 ml stoppered glass centrifuge tubes, and add 20 μL of internal standard mixed solution (1000 ng·ml -1 ), add 4 ml of 0.5% formic acid-acetonitrile, vortex mix for 1 min, and ultrasonically extract for 10-15 min.

[0097] Step (3): Purification

[0098] Add 300mg anhydrous NaCl and 300mg anhydrous MgSO to parallel samples 4 , vortexed for 1 min. at 3000 rpm -1 Centrifuge for 5 min, and transfer the supernatant to a corresponding new centrifuge tube. After rinsing the original centrifuge tube with 2 ml of 0.5% formic acid-acetonitrile, centrifuge again to get the supernatant, and combine the two supernatants. Add 40 mg PSA, 40 mg C18, 200 mg an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com