Horizontal joint tooth-groove dry-type connection structure of assembly type cavity shear wall

A technology for connecting structures and shear walls, applied in the direction of walls, building components, building structures, etc., can solve the problems of complex construction, unfavorable energy saving and environmental protection, and heavy workload of on-site wet work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings:

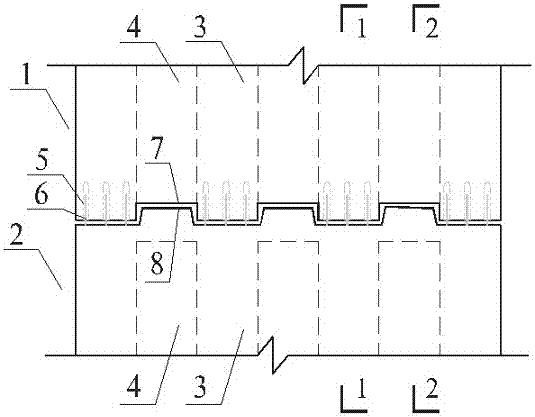

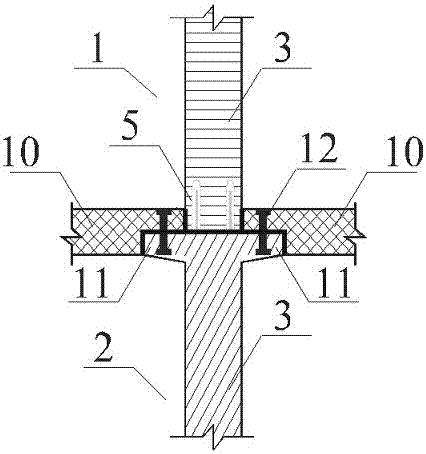

[0022] As shown in the accompanying drawings, the present invention mainly includes an upper-layer prefabricated cavity shear wall sheet (1), a lower-layer prefabricated cavity shear wall sheet (2), a prefabricated floor slab (10), a grouting sleeve (5) and bolts (12). ).

[0023] For the upper-layer prefabricated cavity shear wall sheet (1) and the lower-layer prefabricated cavity shear wall sheet (2) according to the present invention, vertical cavities (4) are reserved in ordinary prefabricated shear walls at intervals. The cavity (4) divides the shear wall into a plurality of wall columns (3), and the two sides in the thickness direction of the vertical cavity (4) are cavity walls (9). The reinforcement of wall column (3) is similar to that of ordinary column, mainly including longitudinal reinforcement (6) and stirrup. The thickness of the cavity wall (9) is rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com