Ni-Mn-Ga alloy fiber capable of being used for textiles and preparation method of Ni-Mn-Ga alloy fiber

An alloy fiber and alloy technology, which is applied in the field of textile fibers, can solve the problems of high stiffness and softness that cannot meet the comfort of clothes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

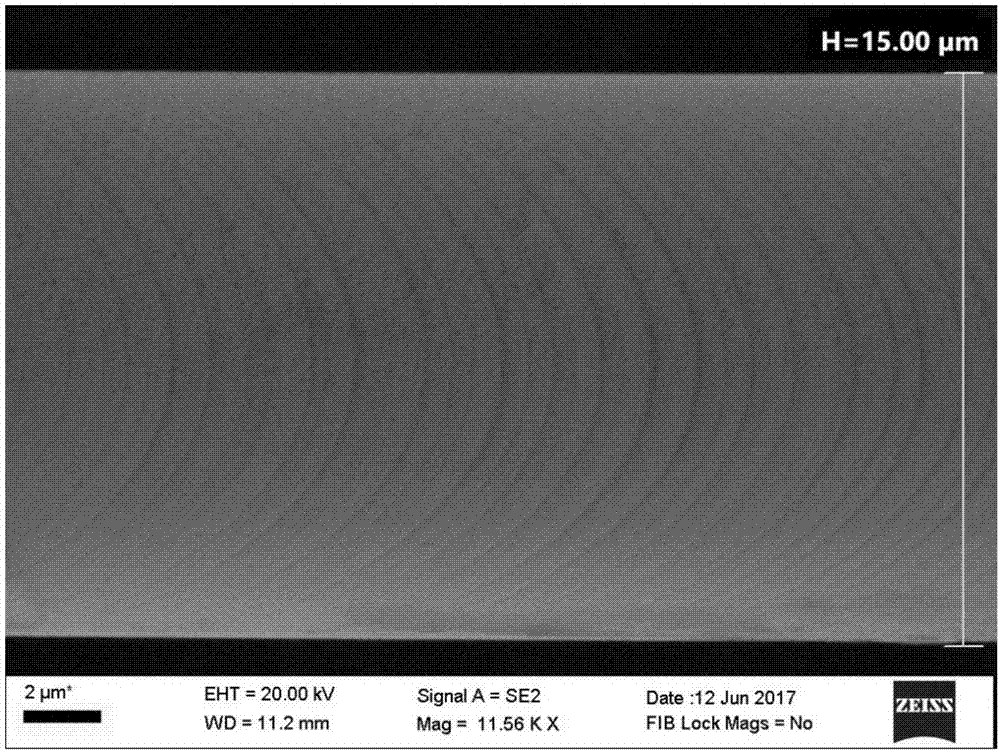

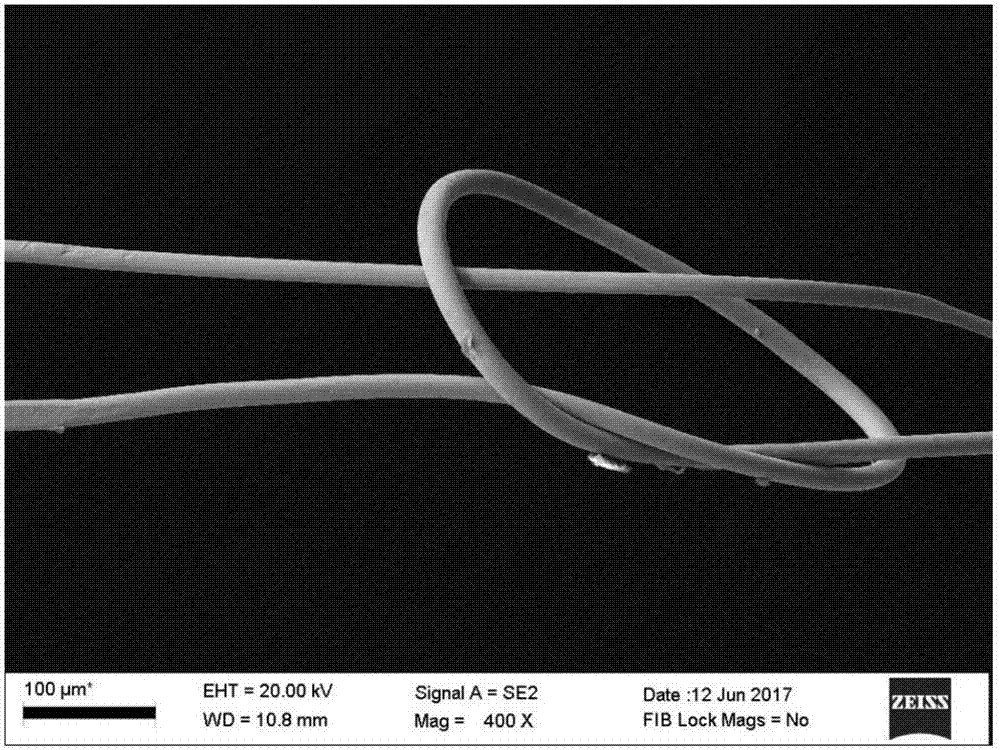

[0029] Example 1: A Ni-Mn-Ga alloy fiber that can be used for textiles, the composition is Ni 52 mn 25 Ga 23 , corresponding to the molecular formula Ni 50+x mn 23+y Ga 27-x-y (x=2, y=2).

[0030] The Ni-Mn-Ga alloy fiber preparation method that can be used for weaving in the present embodiment is as follows:

[0031] (1) Melting

[0032] According to the nominal composition Ni 52 mn 25 Ga 23 The atomic ratio is weighed, and the purity of the elemental Ni, Mn, and Ga used is above 99.98%. After the above simple substances are cleaned by cutting, ultrasonic vibration and other steps, they are put into an electric arc melting furnace and pumped to a high vacuum (~x10 -4 Pa) state, filled with argon to 0.05MPa and then smelted. During the smelting process, the end of the electrode is kept 2-3cm above the sample, the sample is evenly heated, turned over 4 times, and the components are homogenized by electromagnetic stirring to reduce the degree of segregation, and the a...

example 2

[0039] A kind of Ni-Mn-Ga alloy fiber silk that can be used for weaving of example 2, composition is Ni 53 mn 26 Ga 21 , corresponding to the molecular formula Ni 50+x mn 23+y Ga 27-x-y (x=3, y=3).

[0040] The Ni-Mn-Ga alloy fiber silk preparation method that can be used for weaving in the present embodiment is as follows:

[0041] (1) Melting

[0042] According to the nominal composition Ni 53 mn 26 Ga 21 The atomic ratio is weighed, and the purity of the elemental Ni, Mn, and Ga used is above 99.98%. After the above simple substances are cleaned by cutting, ultrasonic vibration and other steps, they are put into an electric arc melting furnace and pumped to a high vacuum (~x10 -4 Pa) state, filled with argon to 0.05MPa and then smelted. During the melting process, the end of the electrode is kept 2-3cm above the sample to heat the sample evenly. The sample was turned over 4 times, and the components were homogenized by electromagnetic stirring to reduce the degr...

example 3

[0050] A kind of Ni-Mn-Ga alloy fiber filament that can be used for weaving, composition is Ni 54 mn 27 Ga 19 , corresponding to the molecular formula Ni 50+ x mn 23+y Ga 27-x-y (x=4, y=4).

[0051] The Ni-Mn-Ga alloy fiber silk preparation method that can be used for weaving in the present embodiment is as follows:

[0052] (1) Melting

[0053] According to the nominal composition Ni 54 mn 27 Ga 19 The atomic ratio is weighed, and the purity of the elemental Ni, Mn, and Ga used is above 99.98%. After the above simple substances are cleaned by cutting, ultrasonic vibration and other steps, they are put into an electric arc melting furnace and pumped to a high vacuum (~x10 -4 Pa) state, filled with argon to 0.05Mpa and then smelted. During the melting process, the end of the electrode is kept 2-3cm above the sample to heat the sample evenly. The sample was turned over 4 times, and the components were homogenized by electromagnetic stirring to reduce the degree of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com