TiO2 immobilized enzyme reactor and application thereof

A technology for immobilizing enzymes and reactors, applied in enzyme production/bioreactors, immobilizing on or in inorganic carriers, etc., can solve the problems of dye toxicity, difficult to degrade, expensive equipment and materials, secondary pollution, etc. The effect of low cost, simple preparation process, and efficient catalytic degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Put 80mg TiO 2 and 9.5 mg of dopamine hydrochloride were added to 50 mL of ultrapure water, and 102 mg of hexamethylenetetramine was added, stirred in a vortex for 30 seconds, incubated at 90°C for 3 hours, centrifuged at 10,000 rpm for 2 minutes to remove the supernatant, and the remaining After the solid was washed with water and ethanol, the dopamine-modified TiO 2 .

[0020] 2. Add 50mg of dopamine-modified TiO 2 Add it into 18mL of Tris-HCl buffer solution with pH=7.0, ultrasonically disperse for 15 minutes, then add 2mL of glutaraldehyde aqueous solution with a volume fraction of 50%, stir at room temperature for 2 hours, and centrifuge to separate the obtained solid product into 1.6mL containing 0.2 In the PBS buffer solution of mmol / L chloroperoxidase pH=4.5, stir at 4°C for 12 hours, centrifuge, discard the supernatant, and dry the remaining solid at 30°C to obtain TiO 2 Immobilized Chloroperoxidase Reactor.

Embodiment 2

[0022] 1. Put 80mg TiO 2 and 9.5 mg of dopamine hydrochloride were added to 50 mL of ultrapure water, and 102 mg of hexamethylenetetramine was added, stirred in a vortex for 30 seconds, incubated at 90°C for 3 hours, centrifuged at 10,000 rpm for 2 minutes to remove the supernatant, and the remaining After the solid was washed with water and ethanol, the dopamine-modified TiO 2 .

[0023] 2. Add 50mg of dopamine-modified TiO 2 Add it into 18mL of Tris-HCl buffer solution with pH=7.0, ultrasonically disperse for 15 minutes, then add 2mL of glutaraldehyde aqueous solution with a volume fraction of 50%, stir at room temperature for 2 hours, and centrifuge to separate the obtained solid product into 1.6mL containing 0.5 mg / mL horseradish peroxidase in PBS buffer at pH = 7.0, stirred at 4°C for 12 hours, centrifuged, discarded the supernatant, and dried the remaining solid at 30°C to obtain TiO 2 Immobilized horseradish peroxidase reactor.

Embodiment 3

[0025] The TiO that embodiment 1 prepares 2 The application of immobilized chloroperoxidase reactor in catalytic degradation of crystal violet, the specific use method is:

[0026] Weigh 10mg TiO 2 Add the immobilized chloroperoxidase reactor to 1.5mL of PBS buffer solution containing 0.5mmol / L crystal violet at pH=2.75, then add 30μL of 0.1mol / L hydrogen peroxide, react at room temperature, and centrifuge after the reaction , take the supernatant to measure its absorbance value. Calculate the degradation rate of the dye according to the following formula:

[0027] η=(A 0 -A t ) / A 0 ×100%

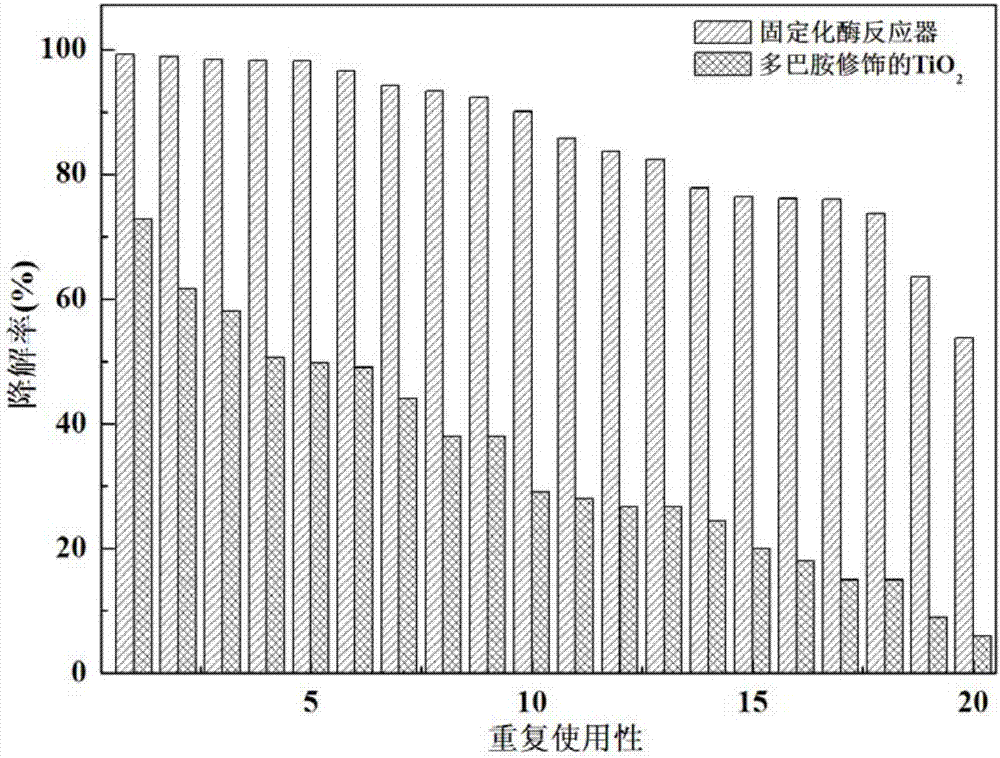

[0028] In the formula, η is the degradation rate, A 0 is the initial absorbance value of the dye, A t is the absorbance value of the dye at time t. The test results show that it only takes 1-2 minutes to degrade more than 90% of the crystal violet in the first 10 degrading processes. like figure 1 Shown, reacted at room temperature for 10min, the enzyme reactor relative to the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Column length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com