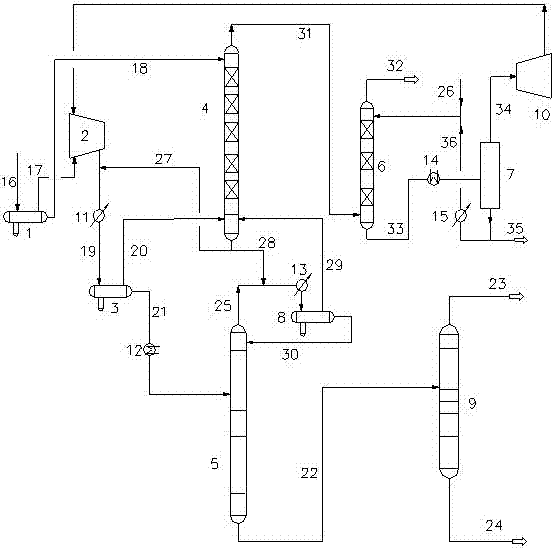

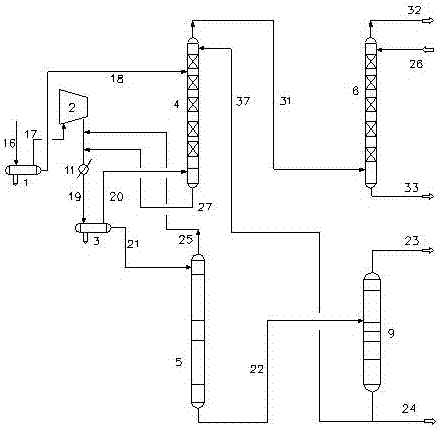

Absorption-stabilization technology and system

An absorption stabilization system and process technology, applied in the petroleum industry, gas mixture processing, hydrocarbon oil treatment, etc., can solve the problems of increasing the internal circulation of gasoline, not too much absorption of diesel oil, economic losses, etc., to reduce the amount of gas phase , flexible control of circulation volume, and the effect of reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Taking the absorption stabilization system of a domestic 1 million tons / year FCC catalytic cracking unit as an example, the ASPEN PLUS process simulation software is used to simulate the process of the present invention, and catalytic diesel is used as the absorbent. The key process parameters are as follows: the outlet of the rich gas compressor The pressure is 1.4 MPa, the operating temperature of the desorption gas balance tank is 40°C, the absorption tower bottom liquid entering the desorption gas balance tank accounts for 40wt% of the total absorption tower bottom liquid phase output, the operating temperature of the rich gas balance tank is 40°C, and the rich gas Equilibrium tank liquid phase heat exchange to 80 ℃ into the desorption tower, the absorption tower is equipped with an intercooler return tower temperature 35 ℃, the ethane content in the deethanized gasoline at the bottom of the desorption tower is 0.1wt%, and the amount of fresh catalytic diesel added is...

Embodiment 2

[0043] Same as Example 1, the difference is that a mixture of 1-butyl-3-methylimidazolium hexafluoroborate and sodium acetate (wherein sodium acetate is 5wt%) is used as the absorbent, and the process parameters are as follows: rich gas compression The outlet pressure of the machine is 1.4 MPa, the operating temperature of the desorption gas balance tank is 40°C, the absorption tower bottom liquid entering the desorption gas balance tank accounts for 40wt% of the total absorption tower bottom liquid phase discharge, and the operating temperature of the rich gas balance tank is 40°C. The liquid-phase heat exchange in the rich gas balance tank reaches 80°C and enters the desorption tower. The absorption tower is equipped with an intercooler to return to the tower. t / h, the vacuum degree of the regeneration tank is 15 KPa, the output of dry gas is 5t / h, the output of liquefied gas is 29t / h, and the output of stable gasoline is 57t / h. The energy consumption of the equipment is show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com