Low dielectric constant glass fiber and preparation method thereof

A low dielectric constant, glass fiber technology, applied in the field of glass fiber, can solve the problems of large fluctuation of glass fiber composition, reduced water resistance of glass fiber, strict furnace temperature requirements, etc., which is beneficial to wire drawing operation and good adhesion. , Improve the effect of large fluctuation of components

Inactive Publication Date: 2017-10-27

CHONGQING UNIV OF TECH

View PDF9 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although it can meet the requirements of use in terms of dielectric properties, the high B 2 o 3 The content of boron seriously volatilizes, and the glass fiber composition fluctuates greatly, which makes the drawing operation difficult. At the same time, the temperature of the kiln is strict, which will reduce the life of the tank kiln. Therefore, the production cost is high and it is difficult to produce on a large scale.

In addition, high B 2 o 3 The content also causes the water resistance of the glass fiber to decrease

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

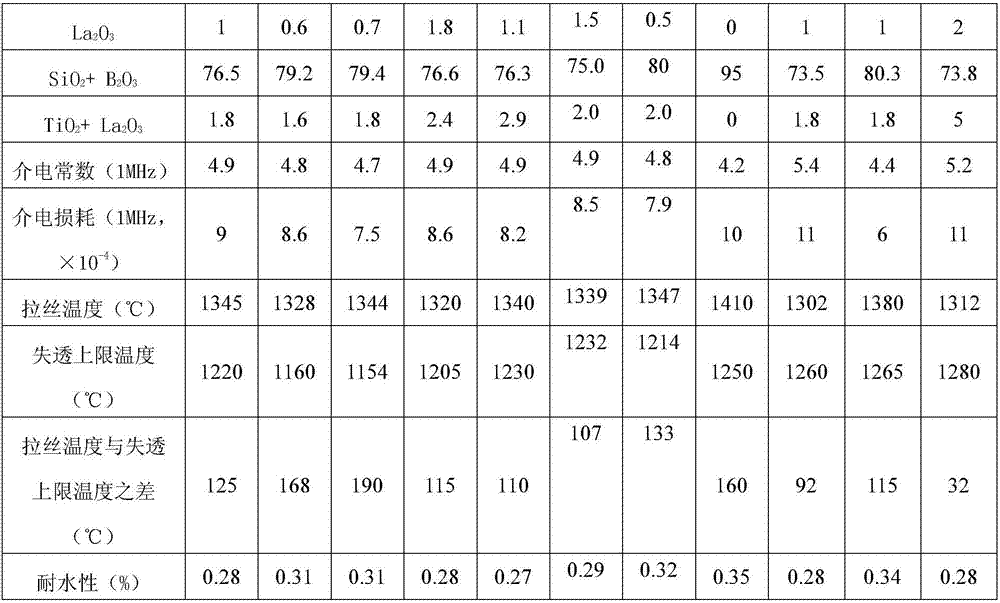

[0023] Embodiment 1-11 is prepared respectively according to the prescription in table 1, and preparation method is:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a low dielectric constant glass fiber and a preparation method thereof. The low dielectric constant glass fiber is prepared from the following components in parts by weight: 62-65% of SiO2, 11-13% of Al2O3, 13-15% of B2O3, 5-8% of CaO, 0.5-2% of TiO2, 0.5-2% of Li2O and 0.5-2% of La2O3, wherein the weight sum of TiO2 and La2O3 is not greater than 3%. The glass fiber which adopts the proportion has excellent processing property and dielectric property, and the fiber-forming temperature of the glass fiber is lower than 1350 DEG C; at room temperature, when frequency is 1MHz, a dielectric constant is 4.7-4.9, and dielectric loss is 7-9*10<-4>. The low dielectric constant glass fiber is suitable for serving as the enhancement material of a printed circuit board.

Description

technical field [0001] The invention relates to a glass fiber with low dielectric constant, which is used as a reinforcing material for printed circuit boards, and also relates to a preparation method of the glass fiber. Background technique [0002] In the past ten years, due to the rapid development of the electronic information industry, printed circuit boards have developed in the direction of high density, multi-layer, and super-multi-layer. It acts as a built-in passive component function in a multilayer board, etc. This requires materials with low dielectric constant and dielectric loss. This is because the smaller the dielectric constant of the material, the faster the signal propagation speed; at a certain propagation frequency, the smaller the dielectric loss of the material, the smaller the propagation loss. Printed circuit boards are usually composed of resin and fiberglass. The dielectric properties of resins conventionally used for printed circuit boards are...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03C13/02C08K7/14

CPCC03C13/00C08K7/14

Inventor 田中青黄伟九

Owner CHONGQING UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com