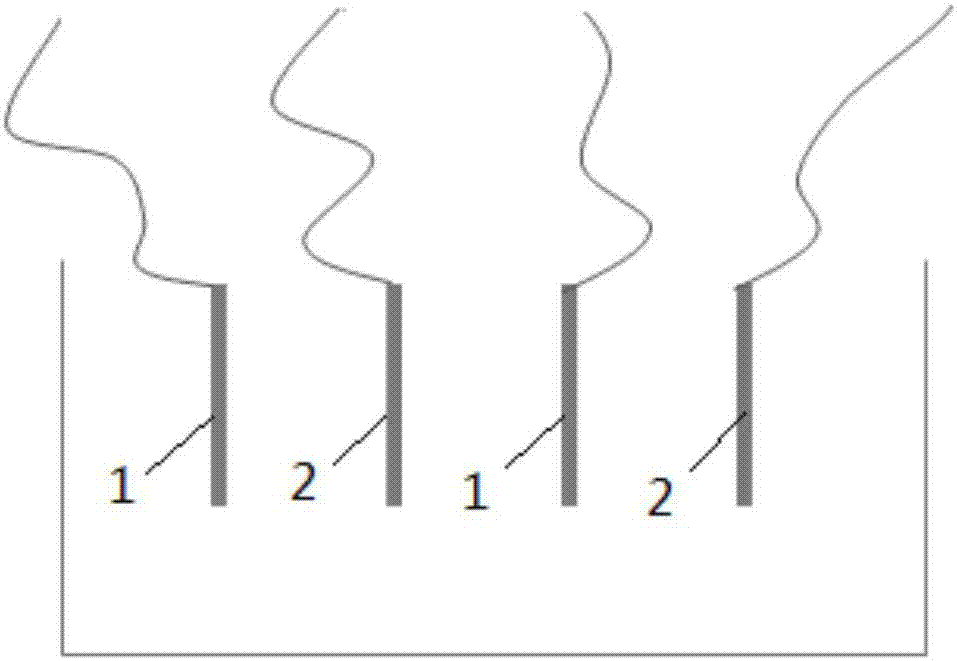

Electrochemical reactor and method for removing coexisting high-calcium and high-chloride ions from wastewater

A reactor and electrochemical technology, applied in the field of environmental pollution control, can solve the problems of unsuitable wastewater with high chloride ion content, easy passivation and deactivation of electrodes, complicated electrolysis devices, etc. Controlling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare simulated wastewater with an initial concentration of chloride ions of 1000 mg / L and an initial concentration of calcium ions of 8000 mg / L with sodium chloride and calcium oxide, introduce the simulated wastewater to be treated into the reaction tank of the electrochemical reactor, and make the anode and The cathode is immersed in the waste water, a constant current is applied between the cathode and the anode, and the waste water is continuously stirred. The power supply used in the reaction process is a DC power supply, the voltage is 5 volts, the current is 2 amps, and the reaction temperature is 20°C. After 2 hours of electrification, the chloride ion concentration dropped to 290mg / L, and the calcium ion concentration dropped to 6000mg / L.

Embodiment 2

[0039] Sodium chloride and calcium oxide are used to prepare simulated wastewater with an initial concentration of chloride ions of 2000 mg / L and an initial concentration of calcium ions of 4000 mg / L. The simulated wastewater to be treated is introduced into the reaction tank of the electrochemical reactor to make the anode and The cathode is immersed in the waste water, a constant current is applied between the cathode and the anode, and the waste water is continuously stirred. The power supply used in the reaction process is a DC power supply, the voltage is 5 volts, the current is 2 amps, and the reaction temperature is 20°C. After 4 hours of electrification, the chloride ion concentration dropped to 745.71mg / L, and the calcium ion concentration dropped to 1180mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com