Carex baccans nees and longan pulp powder and preparation method thereof

A technology of longan powder and red barnyard, applied in the function of food ingredients, food science, application and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

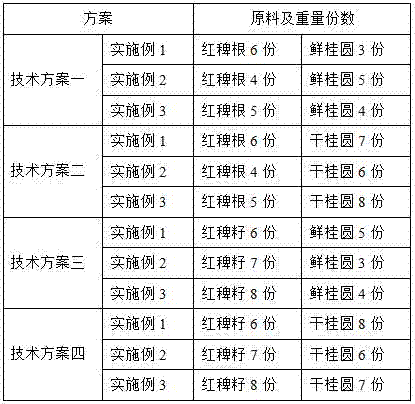

Examples

Embodiment 1

[0050] Method Example 1: Taking Example 1 of Technical Scheme 1 as an example, the preparation method of red barnyard longan powder of Technical Scheme 1 is further described. The preparation method of red barnyard longan powder comprises the following steps:

[0051] a. Processing of raw materials:

[0052](1) Clean the red barnyard root and drain the water, then use a stone mill to crush the red barnyard root, spread salt evenly on the surface, knead and poke it for 4-6 minutes, then let it stand for 25-30 minutes, and then wash it with water Until the salty taste is removed, filter and dry the water for later use. The weight of table salt accounts for 10-15% of the weight of red barnyard barnyard root;

[0053] (2) Fresh longan is peeled and pitted to obtain longan meat, which is kept fresh and stored for later use;

[0054] b. Pre-steaming and beating: Weigh 6 kg of processed red barnyard root and put it in a steamer for steaming for 40 to 50 minutes, then take it out, a...

Embodiment 2

[0057] Method embodiment 2: Taking the embodiment 1 of the technical solution 2 as an example, the preparation method of the red barnyard longan powder of the technical solution 2 is further described. The preparation method of red barnyard longan powder comprises the following steps:

[0058] a. Processing of raw materials:

[0059] (1) Clean the red barnyard root and drain the water, then use a stone mill to crush the red barnyard root, spread salt evenly on the surface, knead and poke it for 4-6 minutes, then let it stand for 25-30 minutes, and then wash it with water Until the salty taste is removed, filter and dry the water for later use. The weight of table salt accounts for 10-15% of the weight of red barnyard barnyard root;

[0060] (2) Dried longan is peeled and cored to obtain longan meat. Weigh 7kg of longan meat, soak it in water at 50-60°C for 12-16 minutes, take it out and filter it dry; put the soaked longan meat into a fresh-keeping bag, and tie the fresh-keep...

Embodiment 3

[0064] Method Example 3: Taking Example 1 of Technical Scheme 3 as an example, the preparation method of red barnyard longan powder of Technical Scheme 3 is further described. The preparation method of red barnyard longan powder comprises the following steps:

[0065] a. Processing of raw materials: clean red barnyard barnyard seeds, filter dry water, peel and remove the core of fresh longan to obtain longan meat;

[0066] b, beating: weighing 6kg of red barnyardgrass seeds and 5kg of longan meat and beating into a slurry, pouring out after repeated beating 3 times to obtain a slurry;

[0067] c. Vacuum concentration: After the slurry returns to normal temperature, use a rotary evaporator to vacuum concentrate the slurry. The vacuum degree of vacuum concentration is 0.08-0.09Mpa, the temperature is 30-40°C, and the time is 55-65min;

[0068] d. Spray drying: Use a spray dryer to dry the vacuum-concentrated slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com