Cable stripping device

A technology of cable and corresponding position, which is applied in the direction of cable installation device, cable installation, dismantling/armored cable equipment, etc., which can solve the problems of low efficiency and inability to realize ring cutting, etc., to enhance wear resistance and improve wear resistance properties and toughness, and the effect of improving wear resistance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

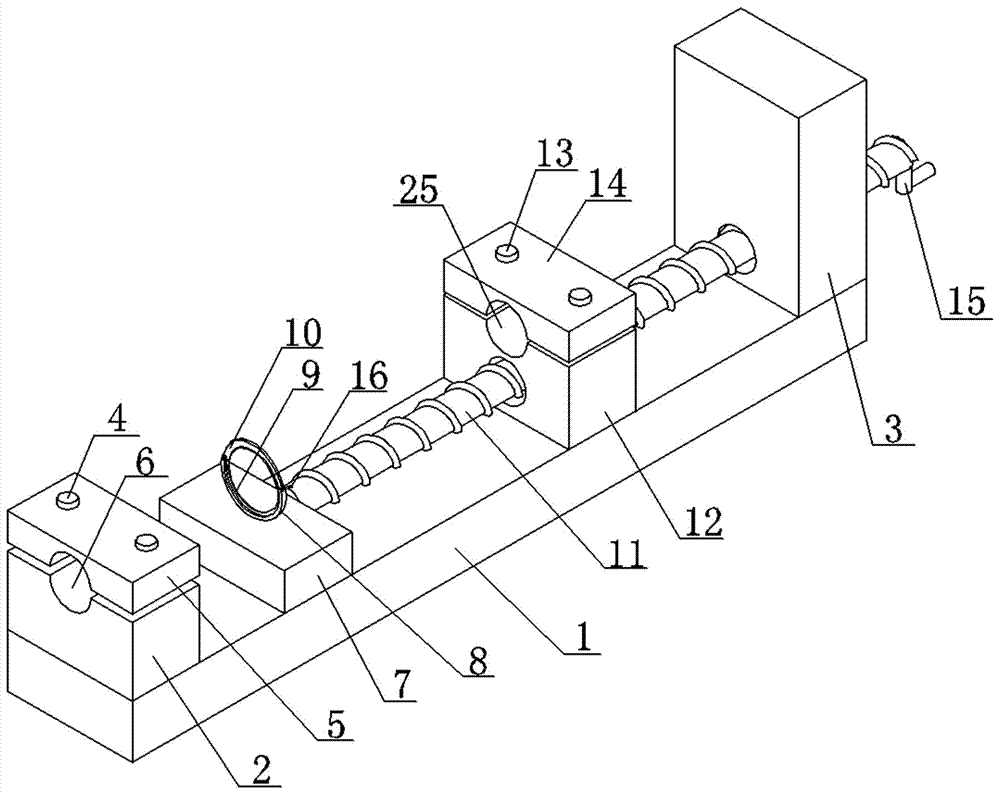

[0029] Such as figure 1 with figure 2 As shown, a cable stripping device includes a base 1, wherein the two sides of the base 1 are respectively provided with a fixed block 2 and a fixed block 2 3, wherein the height of the fixed block 2 3 is greater than the fixed block 2; the two sides of the fixed block 2 are respectively passed through bolts One 4 is connected with briquetting block 1 5, groove 1 6 is arranged on the corresponding positions of fixing block 2 and briquetting block 5 middle part, and the groove 1 6 is used to place cables.

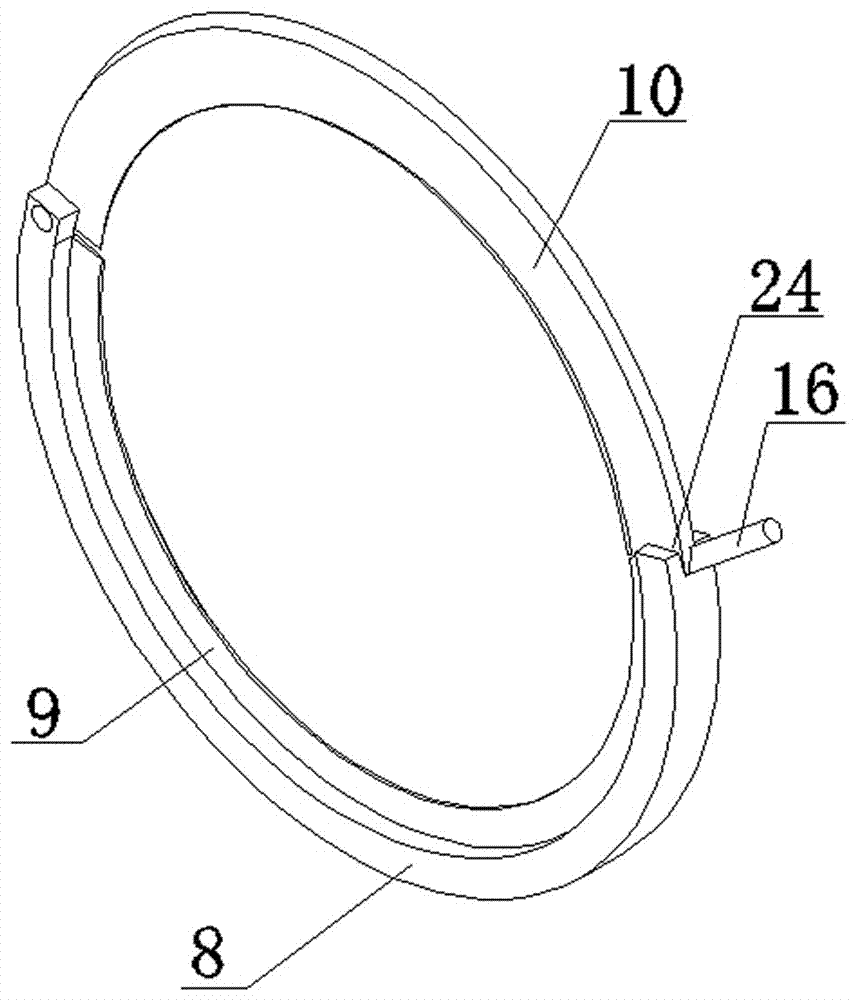

[0030] The base 1 is provided with a fixed block 3 7, wherein the fixed block 3 7 is fixed with an arc-shaped bracket 8, and the arc-shaped bracket 8 is welded on the base 1; the inner side of the arc-shaped bracket 8 is fixed with an arc-shaped blade 1 9, which is used for ring cutting the cable insulation One side of arc support 8 top is hinged arc blade 2 10, and the other side of arc support 8 top is provided with depression 24, an...

Embodiment 2

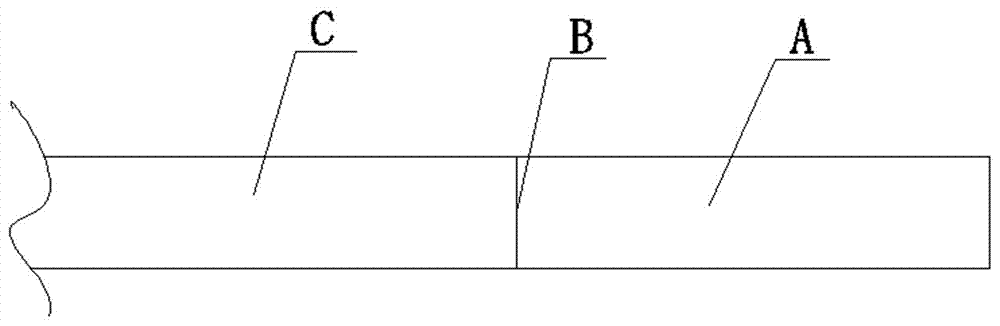

[0035]The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 4 with Figure 5 As shown, the fixed block three 7 is away from the side fixed frame 17 of the fixed block one 2, wherein the chute 18 is fixed between the top of the frame 17 and the top of the two 3 of the fixed block, and the chute 18 includes an upper chute 22 and a lower chute 23. The width of chute 22 is greater than the width of chute 23; slide block 2 19 is set in chute 22, and slide block 2 19 is threadedly connected to screw rod 20, and blade 21 is set at the bottom of screw rod 20; wear out.

[0036] With the above structure, when cutting the cable insulation, the slider 2 19 can be moved to the position in the chute 18, and then the position of the blade 21 can be adjusted by rotating the screw 2 20, so that the cable insulation of section A can be longitudinally cut. Cable stripping is faster and easier to use.

[0037] In the present embodiment, ...

Embodiment 3

[0039] The cable stripping device in this embodiment is the same as that in Embodiment 2.

[0040] The difference is that in this embodiment, the arc-shaped blade one 9 and the arc-shaped blade two 10 are all made of wear-resistant steel, and the wear-resistant steel includes the following chemical components in weight percentage: carbon 0.38%, manganese 3.0%, titanium 0.08%, silicon 0.7%, nickel 0.3%, chromium 0.6%, vanadium 0.15%, molybdenum 0.65%, sulfur 0.02%, and the balance is iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com