Large-area perovskite film, perovskite solar cell module and manufacturing method

A technology of solar cells and manufacturing methods, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as current hysteresis, easy leakage of components, damage to perovskite active layers, etc., and achieve good quality, reduced production time and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

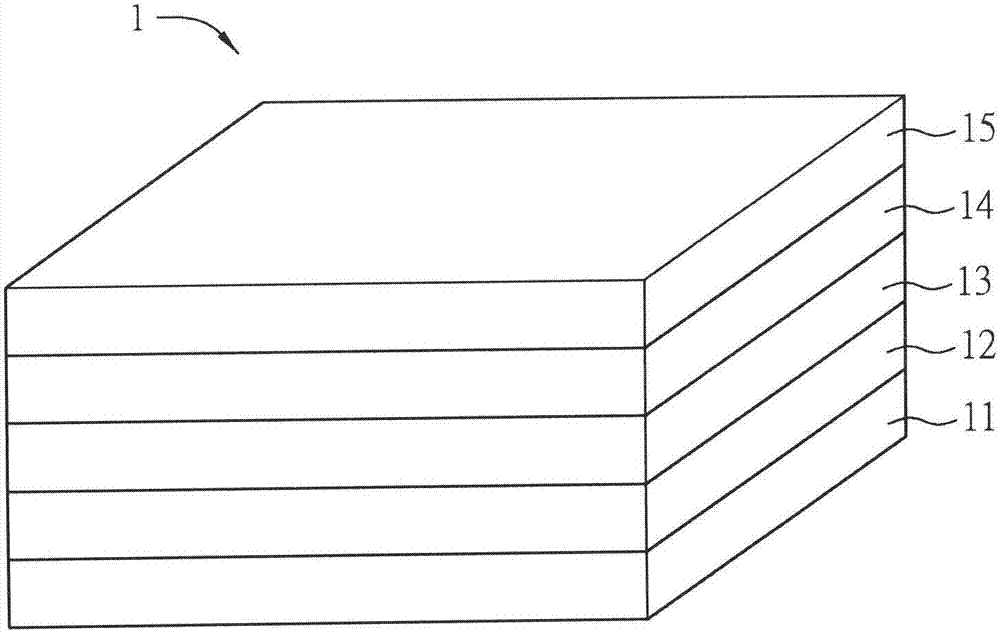

[0040] A method of manufacturing a large-area perovskite film and a perovskite solar cell module according to preferred embodiments of the present invention will be described below with reference to the relevant drawings, wherein the same components will be described with the same reference symbols.

[0041] Perovskite (Perovskite) material is a ceramic oxide with ABX 3 general formula. Among them, A is an alkali metal ion, a methylamine ion (CH 3 NH 3 + ), formamidine ion (NH 2 CH=NH 2 + ), B is at least one of lead (Pb), tin (Sn), germanium (Ge), X is a group VII element (fluorine F, chlorine Cl, bromine Br, iodine I), hexafluoro Phosphate (PF 6 ), at least one of thiocyanic acid (HSCN).

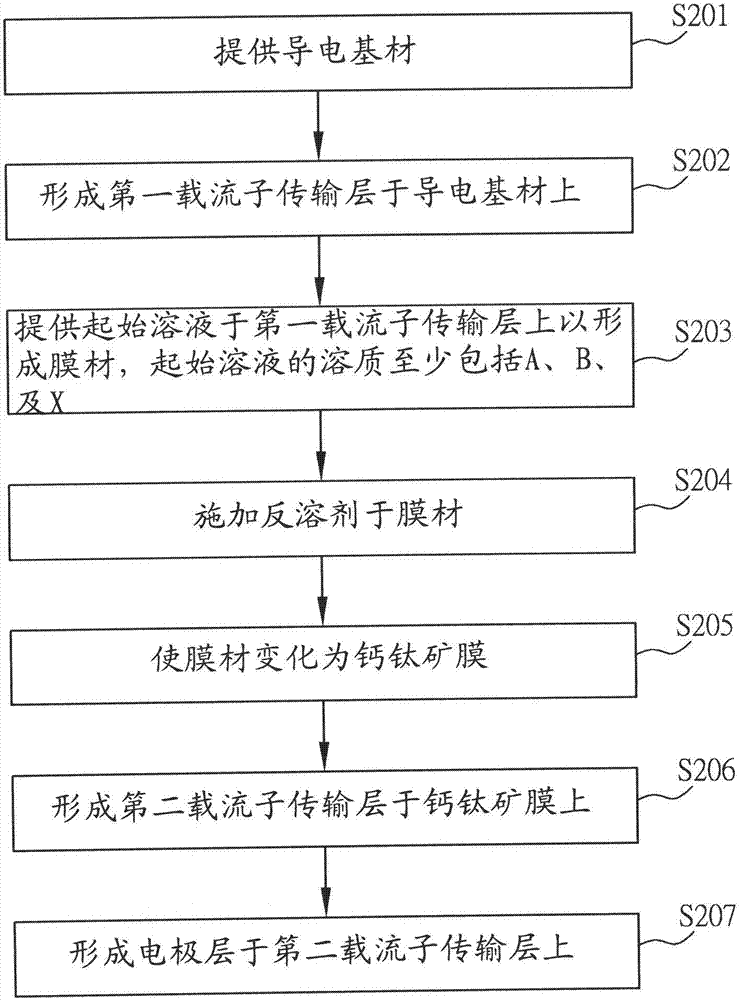

[0042] figure 1 It is a flowchart of a method for fabricating a large-area perovskite film according to an embodiment. Please refer to figure 1 As shown, the fabrication method of large-area perovskite film comprises the following steps:

[0043] Step S101: Provide a starting s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com