Grain refinement method for large-size semi-continuous casting magnesium alloy ingot

A technology of grain refinement and magnesium alloy, which is applied in the field of magnesium alloy materials, can solve problems such as uneven grain size and coarse grain, and achieve macroscopically uniform grain size, fine grain and macroscopically uniform, which is conducive to popularization and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

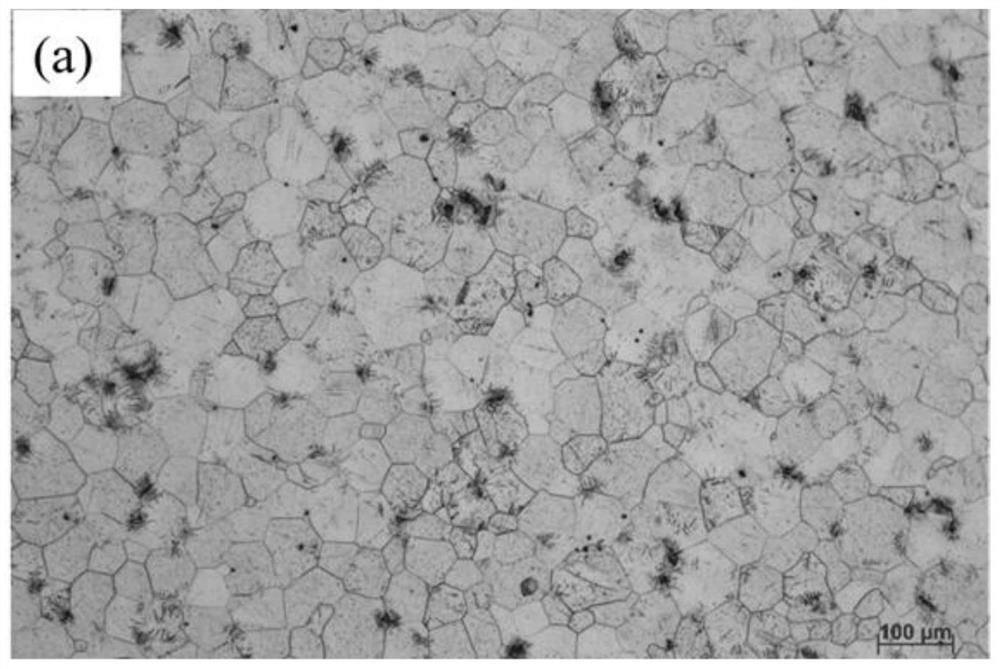

Embodiment 1

[0042]A large-scale semi-continuous casting high rare earth magnesium alloy ingot. The magnesium ingot has a diameter of 200mm and a length of 1m. The contents of each component and their mass percentages: Gd is 15%; Zn is 1%; Zr is 0.5%; the balance It is Mg and unavoidable impurity elements (<1%).

[0043] A method for preparing a large-scale semi-continuous casting high rare earth magnesium alloy ingot, comprising the following steps:

[0044] S1. According to the size of the magnesium ingot and the burning of the alloy, the batching is carried out, and the intermediate alloy is preheated;

[0045] S2. Add magnesium ingots to the smelting furnace, and add various intermediate alloys at the required temperature, stir until completely melted, and transfer the magnesium melt to the refining furnace after smelting;

[0046] S3. Raise the temperature of the melt to 710°C, select JDMJ as the refining agent, refine for 5 minutes, skim off the surface scum after refining, and tran...

Embodiment 2

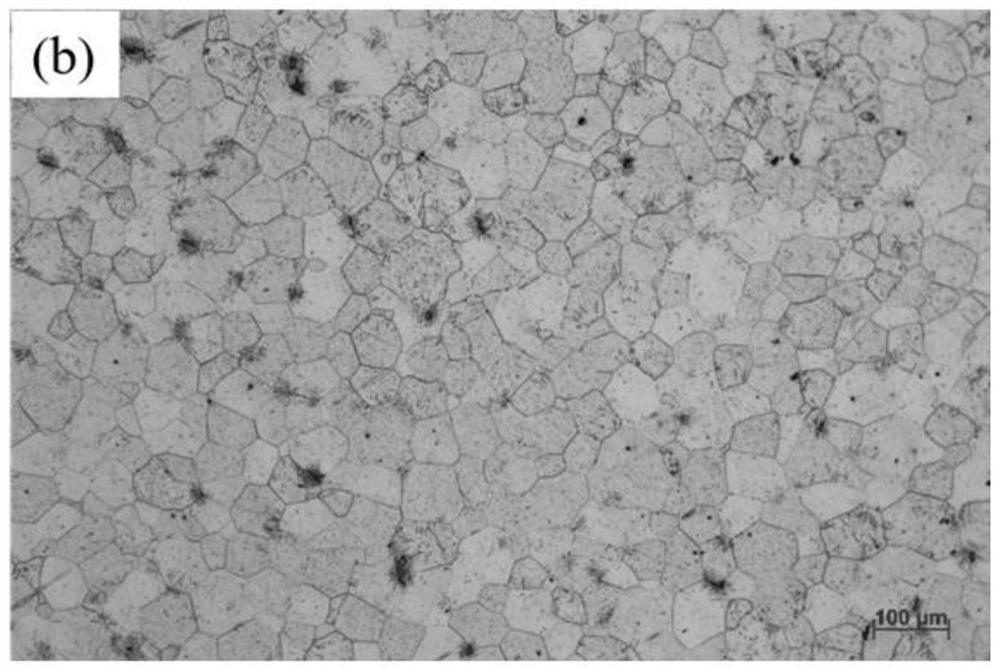

[0051] A large-scale semi-continuous casting high rare earth magnesium alloy ingot. The magnesium ingot has a diameter of 300mm and a length of 1m. The components and their mass percentage contents are as follows: Gd is 10%; Zr is 0.4%; Ti is 0.1%; the balance is Mg and unavoidable impurity elements (<1%).

[0052] A method for preparing a large-scale semi-continuous casting high rare earth magnesium alloy ingot, comprising the following steps:

[0053] S1. According to the size of the magnesium ingot and the burning of the alloy, the batching is carried out, and the intermediate alloy is preheated;

[0054] S2. Add magnesium ingots to the smelting furnace, and add various intermediate alloys at the required temperature, stir until completely melted, and transfer the magnesium melt to the refining furnace after smelting;

[0055] S3. Raise the temperature of the melt to 710°C, select JDMJ as the refining agent, refine for 5 minutes, skim off the surface scum after refining, a...

Embodiment 3

[0060] A large-scale semi-continuous casting high rare earth magnesium alloy ingot. The magnesium ingot has a diameter of 300mm and a length of 1m. The contents of each component and their mass percentages are as follows: Gd is 9%; Y is 4%; Zn is 1%; Zr is 0.4 %; the balance is Mg and unavoidable impurity elements (<1%).

[0061] A method for preparing a large-scale semi-continuous casting high rare earth magnesium alloy ingot, comprising the following steps:

[0062] S1. According to the size of the magnesium ingot and the burning of the alloy, the batching is carried out, and the intermediate alloy is preheated;

[0063] S2. Add magnesium ingots to the smelting furnace, and add various intermediate alloys at the required temperature, stir until completely melted, and transfer the magnesium melt to the refining furnace after smelting;

[0064] S3. Raise the temperature of the melt to 710°C, select JDMJ as the refining agent, refine for 5 minutes, skim off the surface scum af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com