Armored vehicle with central spine girder driving double-V-shaped multistage small-angle lightning protection structure

A multi-level, small-angle technology, applied in armored vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as increasing the center of gravity of the vehicle, a single armored vehicle, and reducing the survivability of the vehicle battlefield. good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

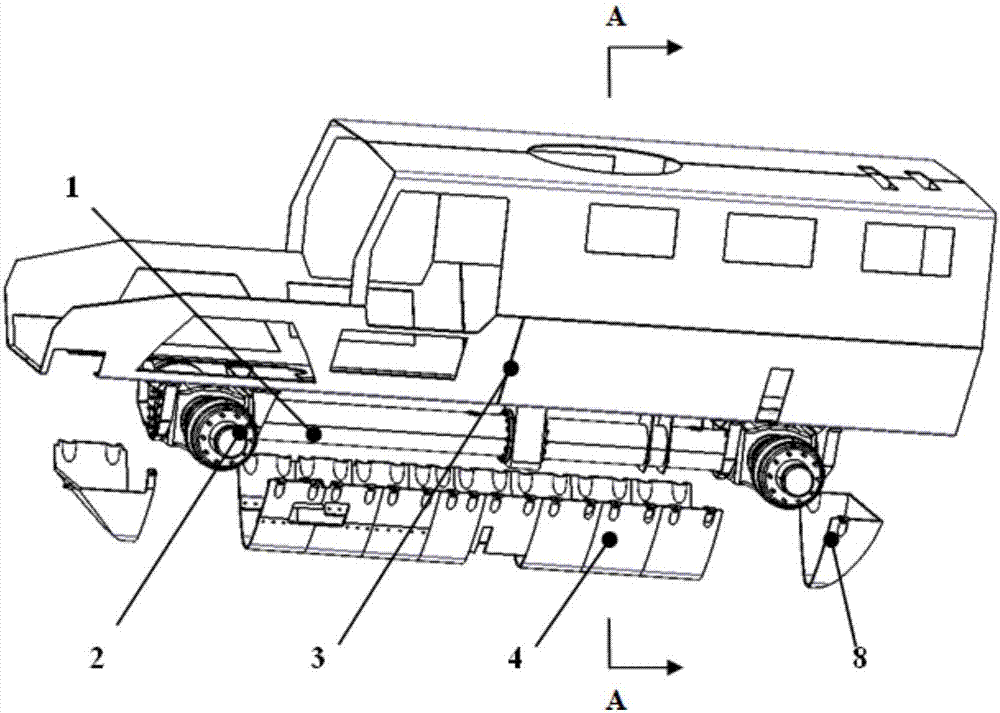

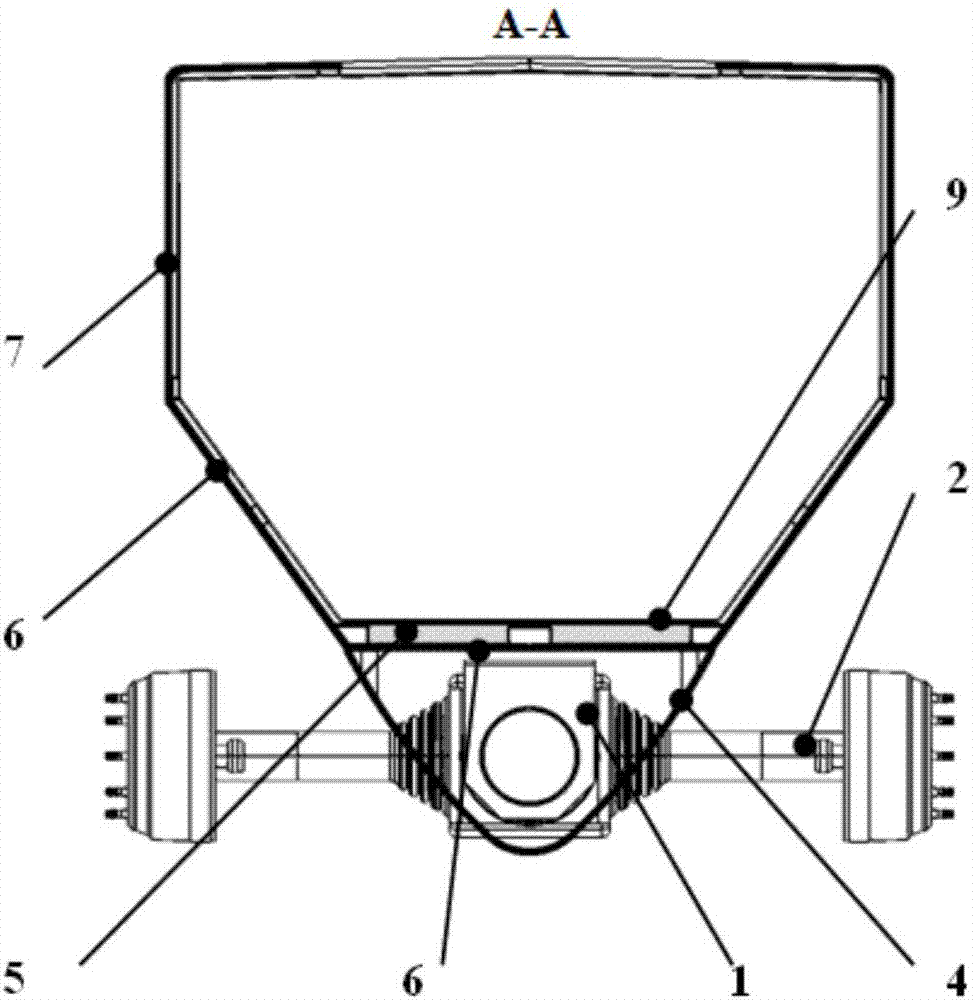

[0011] As shown in the figure, it is an armored vehicle with a double-V-shaped multi-level small-angle lightning protection structure driven by a central spine beam. Including: central spine beam transmission structure 1, full-floating swinging half-shaft suspension 2, one-piece welded body 3, bottom assembled V-shaped guard plate 4, front bottom guard plate 8, flexible non-contact between the body armor plate and the inner wall Metal material 5 and floor 9.

[0012] The cabin adopts an integrated welded combination structure: the bottom armor of the passenger compartment is designed with a V-shaped lightning protection structure, which is welded with the upper U-shaped armor to improve the overall rigidity. The V-shaped angle at the bottom is 72°, which can effectively resist mines and other explosives at the bottom Shock and vibration generated when an explosion occurs. The assembled V-shaped guard plate at the lower part of the vehicle is made of special materials, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com