Air intake system for double tracked all-terrain armored vehicle

A technology of air intake system and crawler type, applied in the direction of charging system, fuel air intake, fuel air filter, etc., to achieve high degree of automation, reduce particles and dust, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

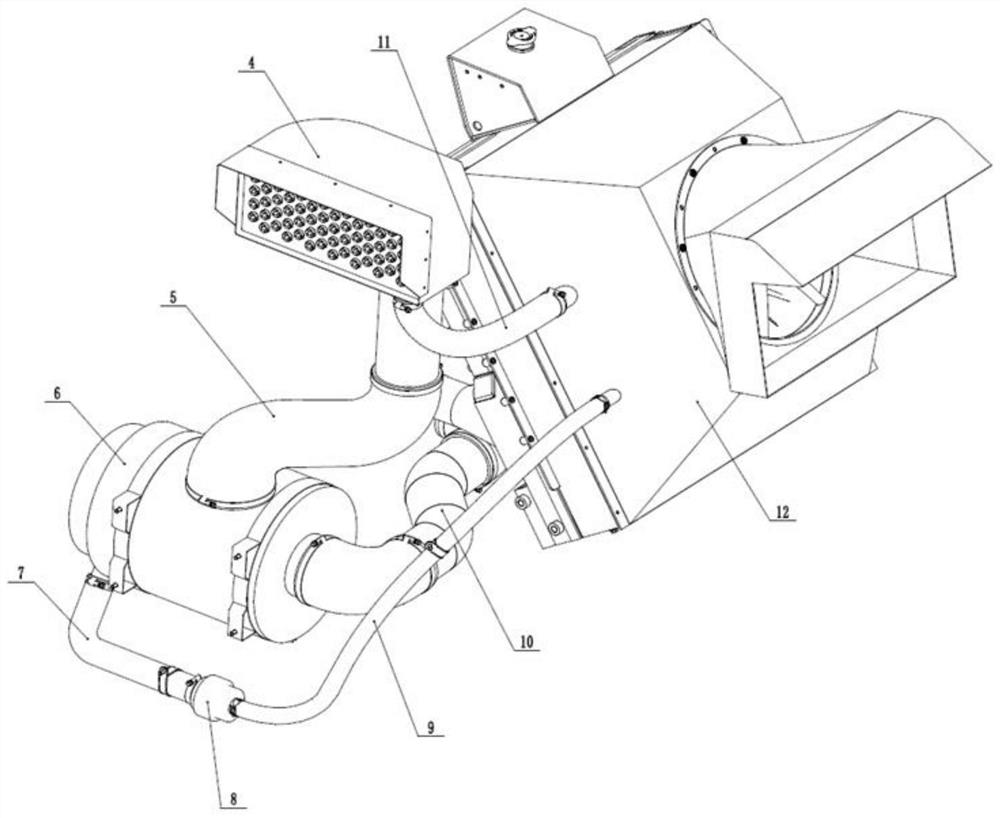

[0057] like figure 2 As shown, a dual-section tracked all-terrain armored vehicle air intake system is proposed, including an air pre-filter 4, an air intake pipe I5, an air filter 6, a dust exhaust pipe I7, an intake pipe II10, and a dust exhaust pipe III11;

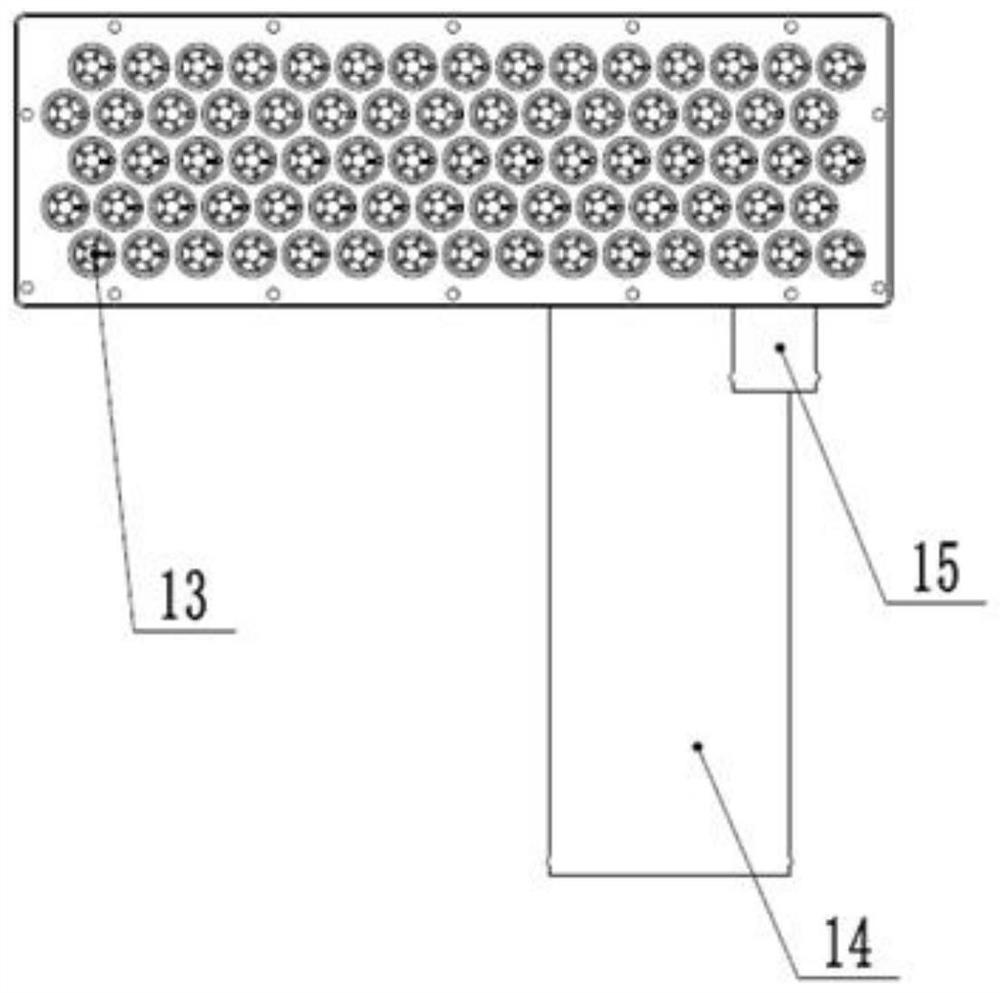

[0058] like image 3 and Figure 4 As shown, the air pre-filter 4 includes a casing, a cyclone separator 13, a pre-filter air outlet pipe I14, and a pre-filter air outlet pipe II 15; the interior of the casing is divided into a chamber I and a chamber II, and the cyclone separator 13 One end of the pre-filtered air pipe II15 is fixed through the other side of the chamber I of the housing, and one end of the pre-filtered air pipe I14 is penetrated and fixed to the casing. one side of chamber II of the body;

[0059] The other end of the prefiltered air outlet pipe I14 is connected with one end of the intake pipe I5, and the other end of the intake pipe I5 is connected with the air inlet of the air cleaner 6;

[0060...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com