Energy-saving control system of refrigeration compressor unit

An energy-saving control system and refrigeration compression technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of rising equipment damage and renewal, increasing use costs, and high levels, so as to reduce operating energy consumption and noise, The effect of reducing the number of starts and stops and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The energy-saving control system of a kind of refrigeration compressor of the present invention is described in further detail below in conjunction with accompanying drawing:

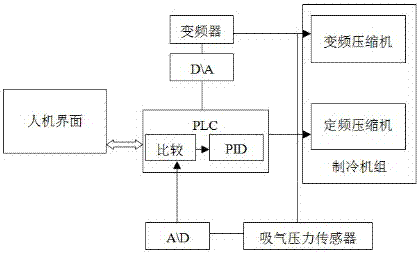

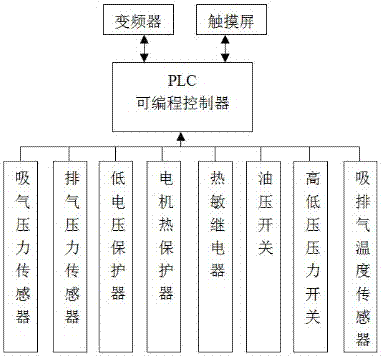

[0025] Such as figure 1 As shown, an energy-saving control system for a refrigeration compressor unit includes a refrigeration unit, a PLC controller, a human-machine interface, a frequency converter, and a suction pressure sensor. The refrigeration unit includes a fixed-frequency compressor and a variable-frequency compressor. The controller controls the speed of the frequency conversion compressor, so that the suction pressure of the frequency conversion compressor is controlled at a value corresponding to the controlled ambient temperature, which not only saves electric energy, but also greatly improves the temperature control accuracy; The air pressure sensor is used to obtain the suction pressure of the suction port of the variable frequency compressor in real time, and transmit the suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com