Variable assembly-type automobile brake caliper cover

A prefabricated, brake card technology, applied in the direction of brake type, brake components, mechanical equipment, etc., can solve the problem that the caliper cover cannot be well applied to the calipers of various models, and achieve the effect of good heat dissipation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

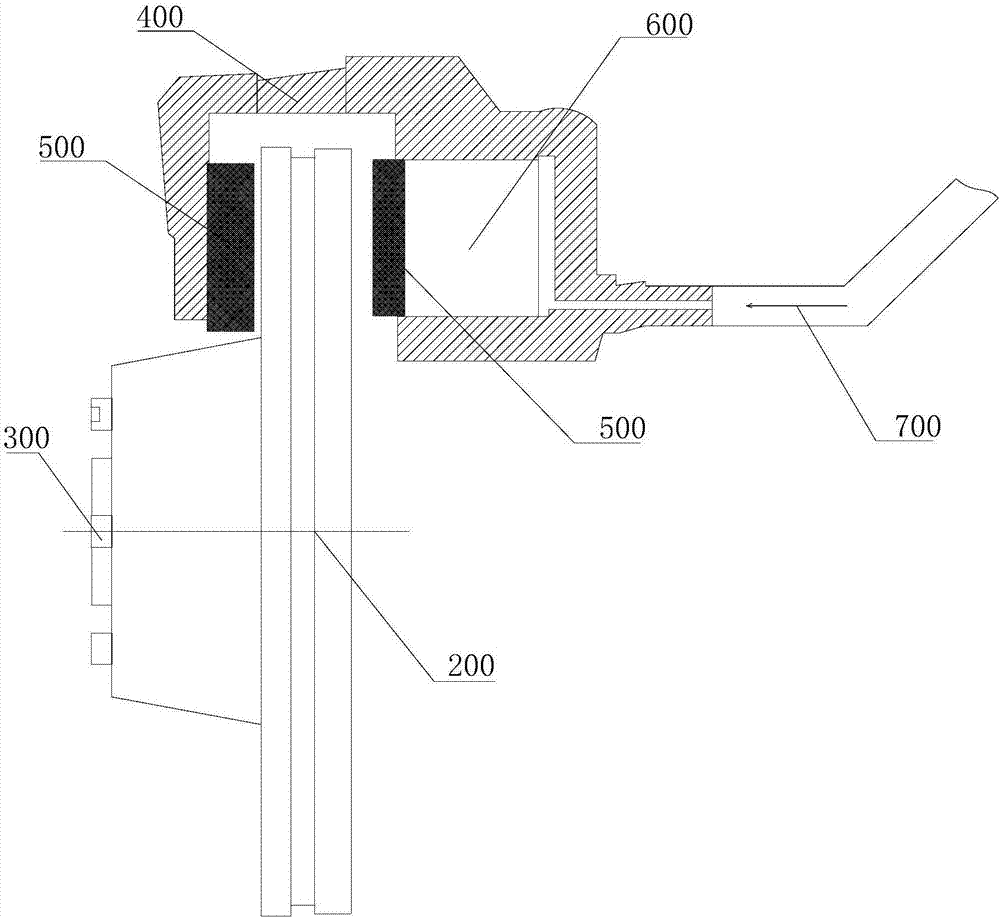

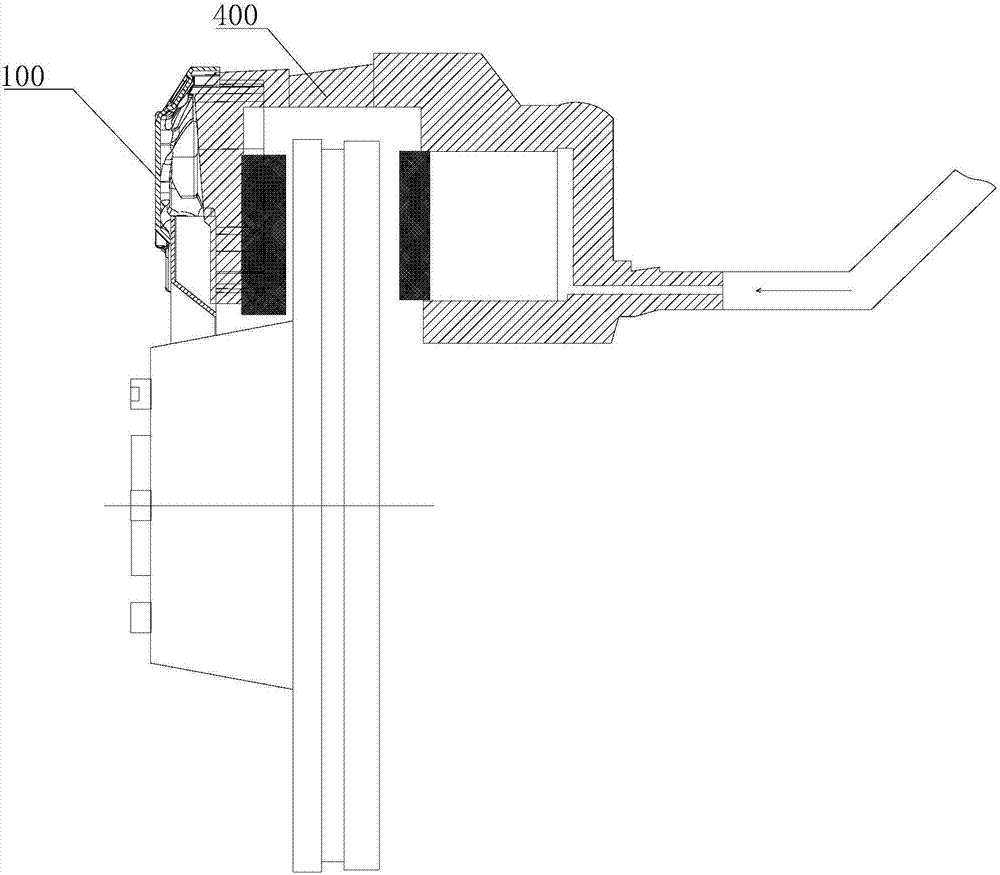

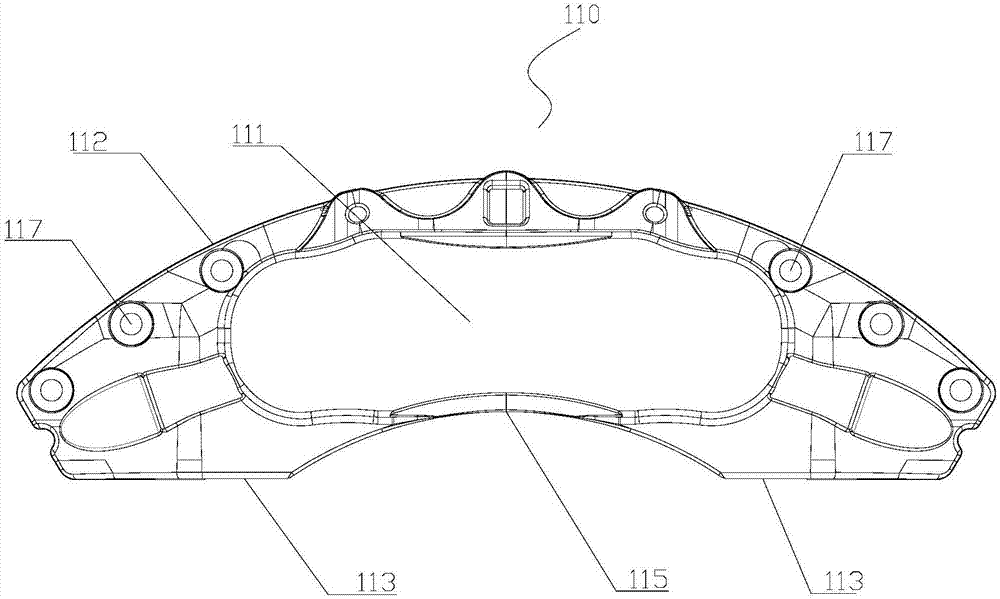

[0039] like Figure 3-5 , 7, the present invention provides a first variable assembly type automobile brake caliper cover 100, including a caliper cover main body 110 and an insert, and the caliper cover main body 110 includes a cover plate 111, an upper arc-shaped side plate 112 and a lower arc shaped side plate 113, the upper arc-shaped side plate 112 and the lower arc-shaped side plate 113 are respectively arranged on the upper and lower sides of the cover plate 111, and the upper arc-shaped side plate 112 and the lower arc-shaped side plate 113 is connected and closed at both ends to form the accommodating cavity of the main body 110 of the caliper cover. A second notch 115 is opened in the middle of the lower arc-shaped side plate 113, and the insert is arranged on the second notch 115. , the accommodating cavity of the insert and the accommodating cavity of the caliper cover main body 110 are installed on the outer side of the automobile caliper 400 .

[0040] Wherein, ...

Embodiment 2

[0051] On the basis of Example 1, such as Figure 8 As shown, the insert is the second insert 130 , and the side of the second insert 130 facing the hub 300 is provided with an arc-shaped side plate.

[0052] Wherein, both the caliper cover main body 110 and the second insert 130 are made of aluminum alloy, and are connected to the automobile caliper 400 through a connecting bracket. The heat of the caliper can be dissipated through the aluminum alloy caliper cover, and the good heat dissipation performance of the aluminum alloy can help the caliper dissipate heat.

Embodiment 3

[0054] On the basis of Example 1, such as Figure 9 , 12 13, the insert is a third insert 140, and the third insert 140 is provided with a plane side plate on the side facing the hub 300.

[0055] Wherein, both the caliper cover main body 110 and the third insert 140 are made of aluminum alloy, and are connected to the automobile caliper 400 through a connecting bracket. The heat of the caliper can be dissipated through the aluminum alloy caliper cover, and the good heat dissipation performance of the aluminum alloy can help the caliper dissipate heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com