Bi-directional limiting expanding locking type continuous oil pipe combined connector

A two-way limit and locking technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problem that the tensile and torsional resistance of the connector cannot meet the coiled tubing drilling construction and other problems, and achieve the effect of reliable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

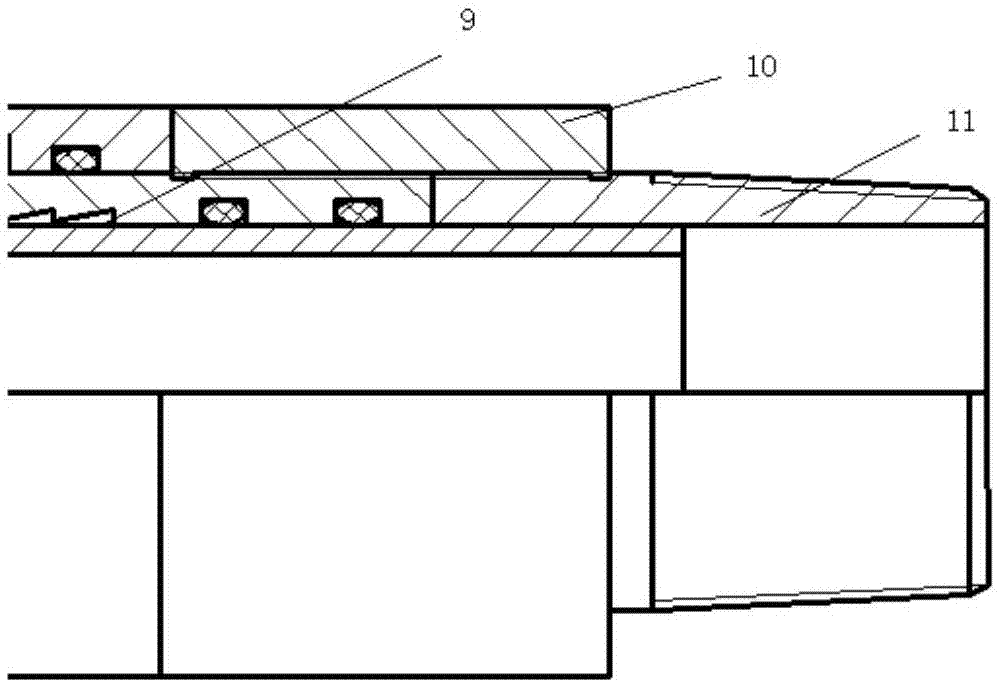

[0021] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] (1) Realization of clamping function

[0023] Such as figure 1 figure 2 As shown, the clamping function of the joint in this design is realized by the principle of expansion, and its basic principle is similar to that of expansion screws. In this joint design scheme, the clamping mechanism is realized by a special upper expansion sleeve 3. The inner surface of the upper expansion sleeve 3 is provided with ratchet teeth 4, and the outer surface is provided with evenly distributed wedge-shaped mating surfaces 5. The clamping function is mainly through the upper expansion sleeve. The ratchet 4 on the inner surface of the sleeve 3 bites into the coiled tubing 8 to realize.

[0024] (2) Realization of locking function

[0025] Such as Figure 4 As shown, the locking function of the joint in this design is main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com