Thiotriazinone 'phosphorus-silicon-nitrogen' oligomer-form intumescent flame retardant and synthetic process thereof

A technology of intumescent flame retardant and synthesis method, which is applied in the field of environmentally friendly halogen-free flame retardant products, can solve problems such as insufficient proportions, and achieve the effects of reasonable proportions, good char formation ability, and good char formation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

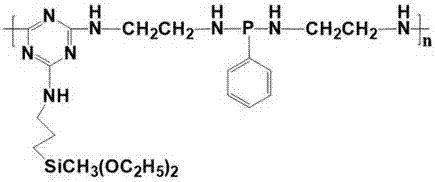

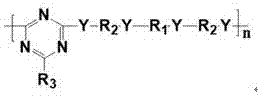

[0037] The synthesis steps of the "phosphorus-silicon-nitrogen" oligomer type intumescent flame retardant containing a triazine ring are as follows:

[0038] step one

[0039] In a 1000ml three-necked flask equipped with a reflux condenser, a stirrer, and a constant pressure dropping funnel, add 92.25g (ie 0.5mol) of cyanuric chloride, then add 200ml of acetonitrile, and place the three-necked flask in an oil bath. Stir well to disperse cyanuric chloride evenly, add 110.69 g (0.5 mol) of γ-aminopropyltriethoxysilane (KH550) dropwise into the three-necked bottle, and 50.6 g (0.5 mol) of triethyl The amine is added dropwise with a constant pressure funnel, the pH is controlled between 5-7, the reaction temperature is controlled at -10°C, and the reaction time is 4 hours to obtain a silicon-containing monobasic substituted product of cyanuric chloride (CNC-Si);

[0040] step two

[0041] Add 60.10g (ie 1mol) of ethylenediamine, 350mL of chloroform and 101.19g (ie 1mol) of triet...

Embodiment 2

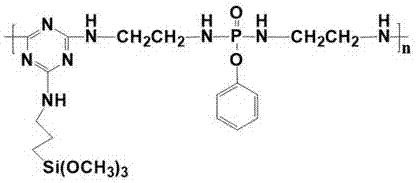

[0049] The synthesis steps of the "phosphorus-silicon-nitrogen" oligomer type intumescent flame retardant containing a triazine ring are as follows:

[0050] step one

[0051] In a 1000ml three-necked flask equipped with a reflux condenser, a stirrer, and a constant pressure dropping funnel, add 184.5g (ie 1mol) of cyanuric chloride, then add 400ml of acetone, place the three-necked flask in an oil bath, and fully Stir to disperse cyanuric chloride evenly, add 179.30 g (1mol) of γ-aminopropyltrimethoxysilane (KH551) dropwise into the three-necked flask, and 101.20 g (1mol) of triethylamine with a constant pressure funnel Add dropwise, control the pH between 5-7, control the reaction temperature at 0°C, and the reaction time is 2.5 hours to obtain a silicon-containing monosubstituted cyanuric chloride (CNC-Si);

[0052] step two

[0053] Add 120.20 g (2mol) of ethylenediamine, 202.40g (ie 2mol) of triethylamine and (500mL) chloroform into another 1000mL three-necked flask, mi...

Embodiment 3

[0061] The synthesis steps of the "phosphorus-silicon-nitrogen" oligomer type intumescent flame retardant containing a triazine ring are as follows:

[0062] step one

[0063] In a 1000ml three-necked flask equipped with a reflux condenser, a stirrer, and a constant pressure dropping funnel, add 184.5g (ie 1mol) of cyanuric chloride, then add 400ml of acetone, place the three-necked flask in an oil bath, and fully Stir to disperse cyanuric chloride evenly, add 191.34 g (ie 1 mol) of γ-aminopropylmethyldiethoxysilane (KH552) dropwise into the three-necked bottle, and 60.59 g (ie 0.5 mol) of triethylene Diamine is added dropwise with a constant pressure funnel, the pH is controlled between 5-7, the reaction temperature is controlled at 10°C, and the reaction time is 1 hour to obtain a silicon-containing monobasic substituted product (CNC-Si) of cyanuric chloride.

[0064] step two

[0065] Add 120.20 g (ie 2 mol) of ethylenediamine, 121.18 g (2 mol) of triethylenediamine and 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com