Automatic express packaging device and method

A technology for adhesive strips and goods, which is applied in the field of automatic express packaging devices, can solve the problems of many manually packaged goods, slowed delivery speed, and discounted delivery efficiency, and achieves the effects of simple structure, labor liberation, and convenient maintenance and care.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

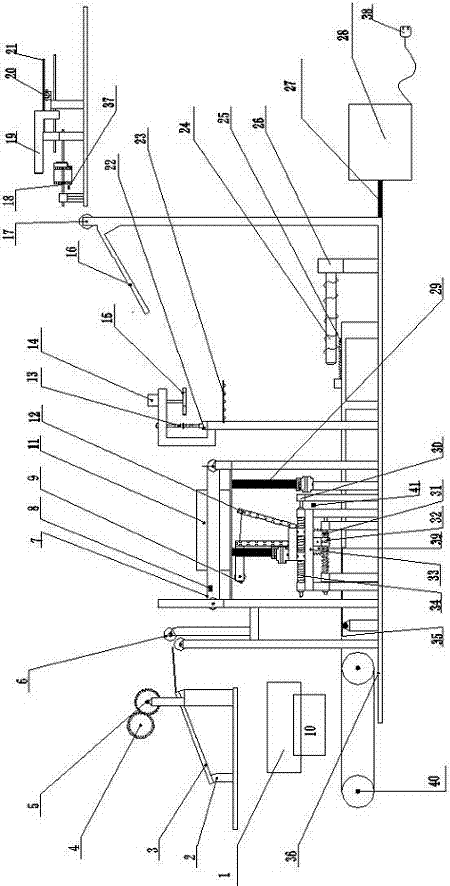

[0037] Such as figure 1 , 2 As shown, an automatic express packaging device includes a bag feeding mechanism, a bag feeding mechanism, a wind bag stretching mechanism, a delivery mechanism, a strip removal mechanism, a bag sealing mechanism, a shipping department, a detection department, and a control department. Fixed by the fixed plate 36; specifically include the following parts:

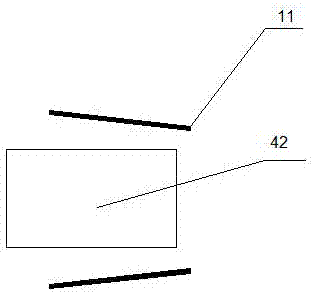

[0038] The bag feeding mechanism includes a friction wheel 4, a bottom plate 3, an adjustment block 2, a bearing 5, and a pair of rollers 6. The friction wheel 4 is fixed on the fixed plate through a central shaft, and the bottom plate 3 is provided with an adjustment block 2, and the adjustment block 2 It can be used to adjust the inclination of the bottom plate 3, and can send multiple courier bags 42 pre-placed at the front end of the friction wheel to the next link in sequence; the counter roller 6 can transport the courier bags to the other side of the bag feeding mechanism;

[0039] The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com