Production equipment intelligent collecting terminal

A technology for intelligent collection and production equipment, applied in metal processing equipment, measuring/indicating equipment, metal processing mechanical parts, etc., can solve problems such as inability to achieve, achieve the effect of simple structure, reduced use cost, and easy debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

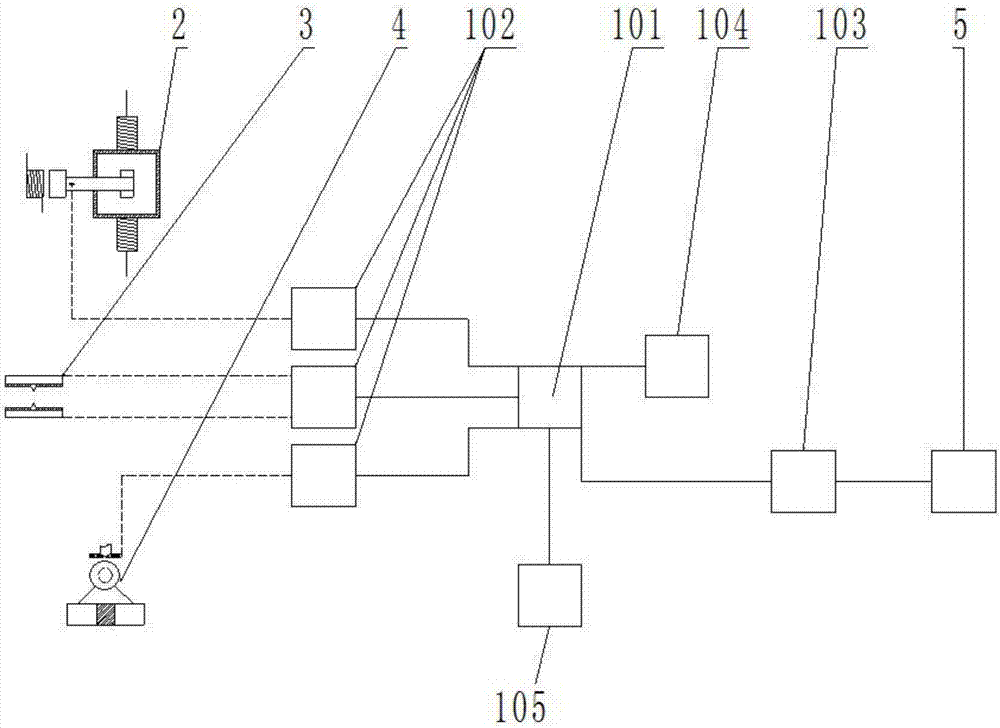

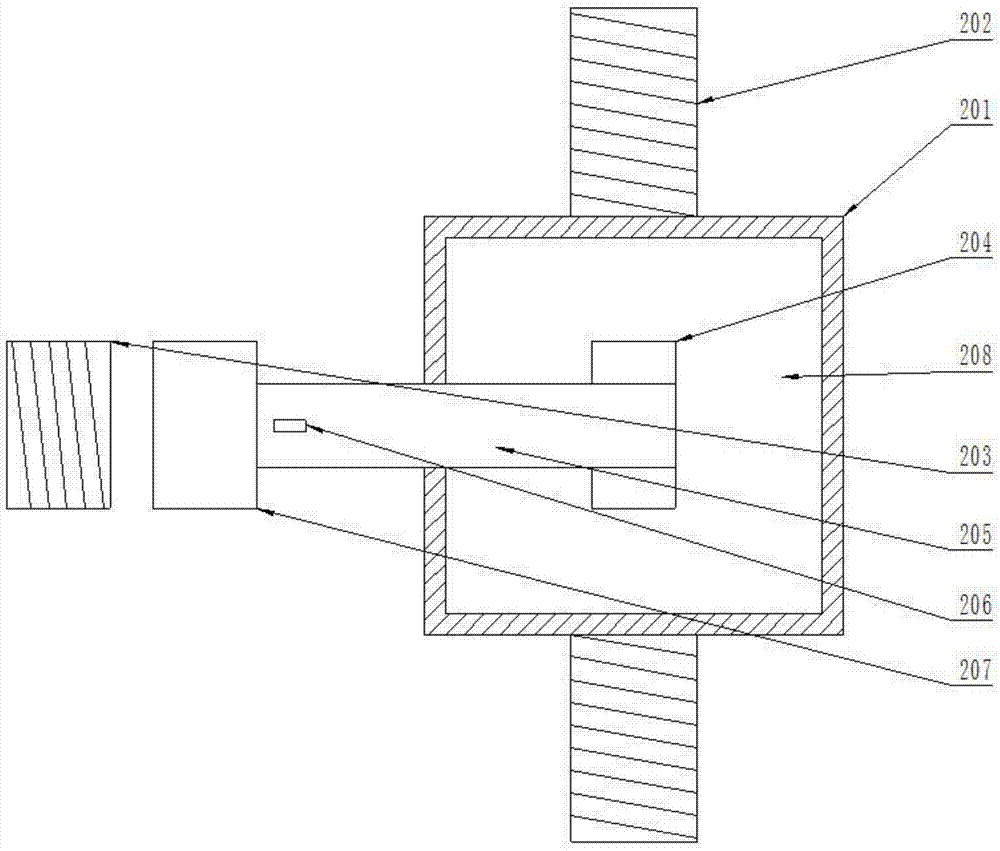

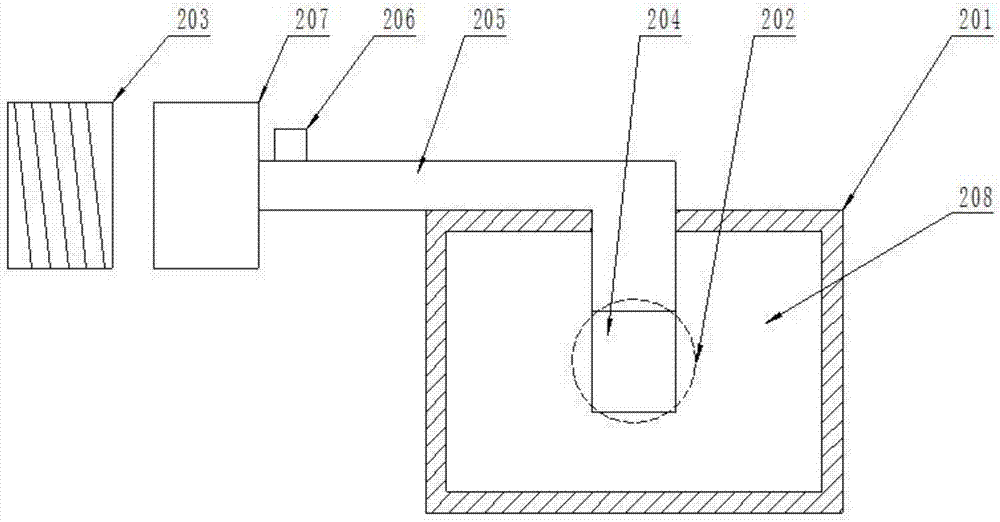

[0018] Intelligent acquisition terminal for production equipment, including: processor 101, digital-to-analog converter 102, data sending port 103, memory 104, display 105, motor action acquisition probe 2, arc type air humidity acquisition probe 3 and vibration data acquisition probe 4; The motion collection probe 2, the arc-type air humidity collection probe 3, and the vibration data collection probe 4 are electrically connected to their respective digital-to-analog converters 102, and the processor 101 is respectively connected to the digital-to-analog converter 102, memory 104, display 405, and data transmission The port 103 is electrically connected; the motor action acquisition probe 2 is set on the motor power supply line, the arc type air humidity acquisition probe 3 is set at a high place in the workshop, the vibration data acquisition probe 4 is installed under the machine tool console, and the data sending port 103 is used for In connection with the central control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com