Dry preparation method for bismuth nanoparticles

A bismuth nanometer and particle technology is applied in the field of preparation of dry bismuth nanoparticles, which can solve problems such as complicated steps and achieve the effect of simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Step 1: Gently scrape the bismuth nanowires grown on the substrate on the micro-grid with a clean blade, scraping 3 times.

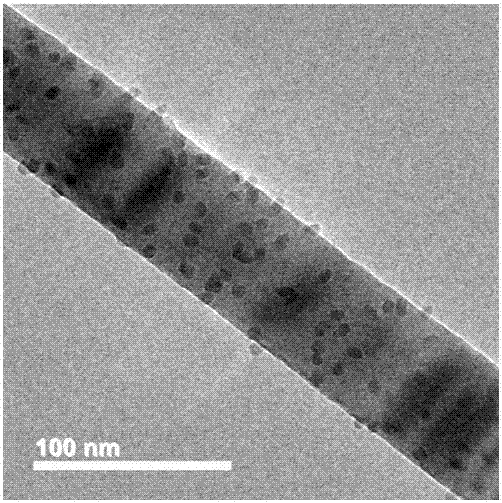

[0018] Step 2: Put the microgrid obtained in Step 1 into a transmission electron microscope, turn on the electron gun, irradiate the electron beam onto the bismuth nanowire, and select 200kV for the accelerating voltage. Bismuth nanowires were observed as figure 1 shown.

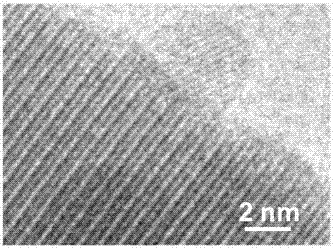

[0019] Step 3: Operate the transmission electron microscope to enter the low-magnification imaging mode for observation, focus on the nanowires, and observe the nanowires until granular bismuth nanoparticles can be seen generated on the bismuth nanowires. The time taken is 2 minutes. The observed results are as figure 2 shown. It can be seen that the prepared bismuth nanoparticles are uniformly distributed on the surface of the bismuth nanowires. image 3 Shown is a high-resolution TEM image of a single bismuth nanoparticle, and it can be seen that the prepared bismuth nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com