Silver nanorod/ polymer/ silver nanosheet core-shell nanometer material and preparation method and application thereof

A technology of core-shell nanomaterials and silver nanorods, which is applied in the field of materials engineering and nanometers, can solve the problems of weak SERS signal, inability to use single-molecule detection, efficiency and reliability of SERS nanoprobes, dissociation or exchange damage, etc., to achieve High SERS signal strength and good electromagnetic coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

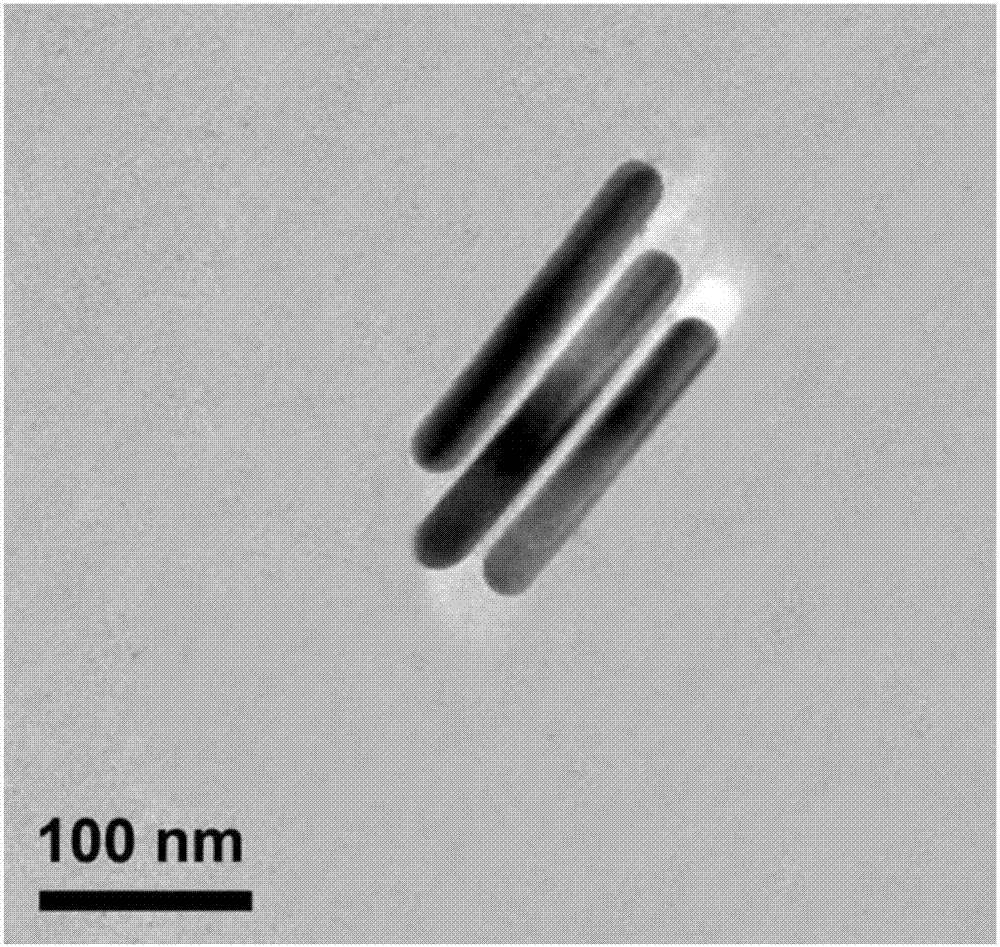

[0041] The preparation method of silver nanorod / polymer / silver nanosheet core-shell nanomaterial comprises the following steps:

[0042] 1. Dissolve 0.5 mg of chloroauric acid, 0.735 mg of sodium citrate and 0.0567 mg of sodium borohydride in 9.65 ml of deionized water, mix and stir for 10 minutes and then stand for 2 hours to obtain an aqueous solution of gold seeds; 2.92 grams of CTAB (hexadecane trimethylammonium bromide), 16 mg of chloroauric acid, 1.36 mg of silver nitrate, 11.26 mg of ascorbic acid, 1.33 ml of hydrochloric acid and 0.4 ml of the above gold seed solution were mixed in 85 ml of deionized water for 1 minute and then centrifuged for 12 hours Obtain gold nano-bipyramids; dissolve all the above-mentioned gold nano-bipyramids, 6.14 grams of CTAC (cetyltrimethylammonium chloride), 81.6 milligrams of silver nitrate and 422.4 milligrams of ascorbic acid in 400 milliliters of deionized water and mix and stir After uniformity, heat and react at 60°C for 4 hours and ...

Embodiment 2

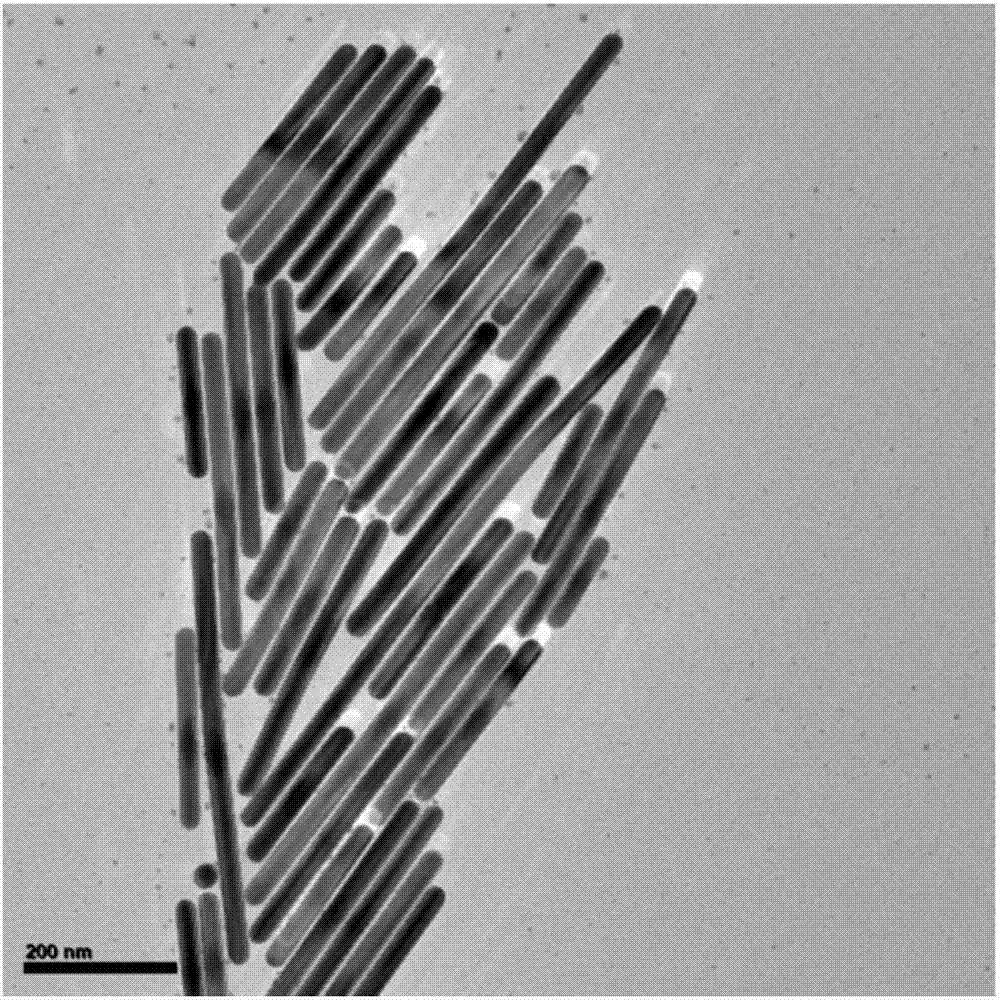

[0051] The preparation method of silver nanorod / polymer / silver nanosheet core-shell nanomaterial comprises the following steps:

[0052] 1. Mix 1 mg of chloroauric acid, 1.47 mg of sodium citrate and 0.1134 mg of sodium borohydride in 19.3 ml of deionized water and stir for 10 minutes to obtain the gold seed aqueous solution; mix 5.84 g of CTAB and 32 mg of chloroauric acid , 2.72 milligrams of silver nitrate, 22.52 milligrams of ascorbic acid, 2.66 milliliters of hydrochloric acid and 0.8 milliliters of the above-mentioned gold seed solution in 170 milliliters of deionized water, mixed and stirred for 1 minute and then left still for 12 hours to obtain gold nano-bicones; Nano biconical, 12.28g of CTAC, 163.2mg of silver nitrate and 844.8mg of ascorbic acid were dissolved in 800ml of deionized water, mixed and stirred evenly, heated and reacted at 60°C for 4 hours, and the precipitate was collected by centrifugation to obtain silver nanorods;

[0053] 2. Get all the silver nan...

Embodiment 3

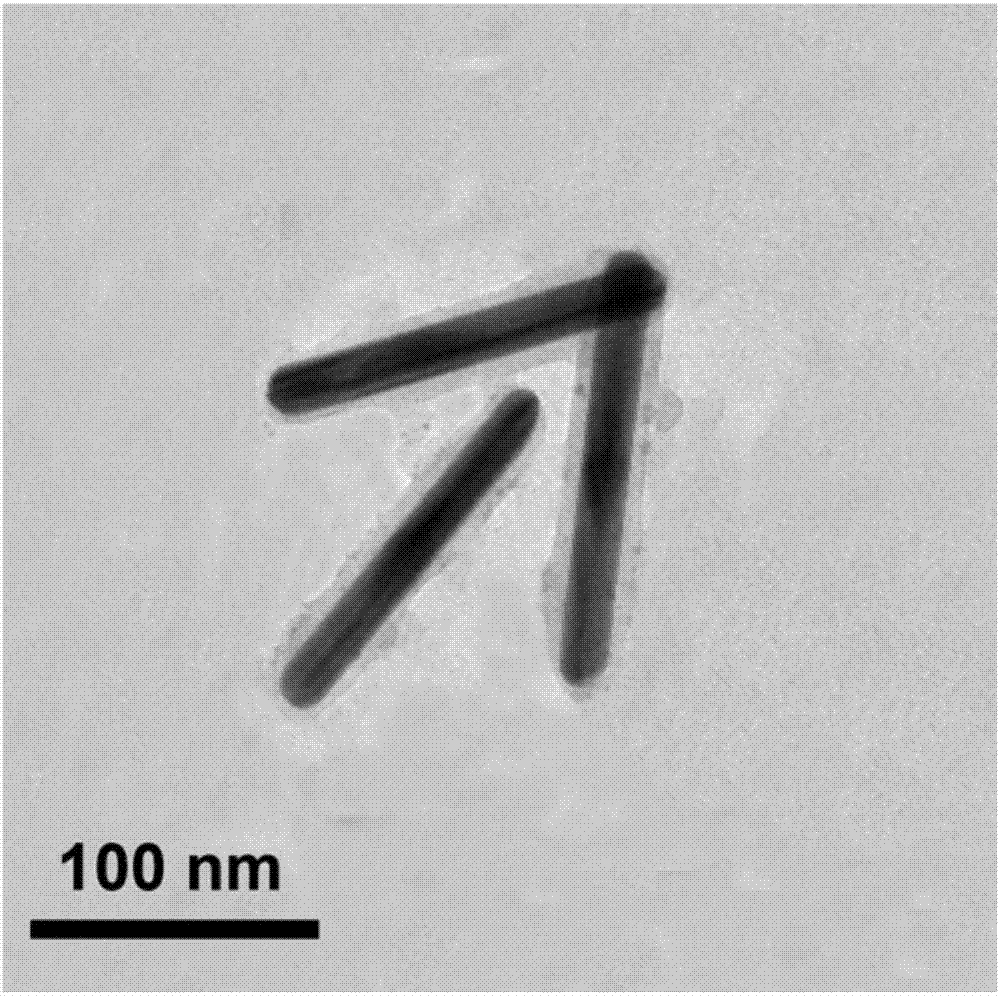

[0060] The preparation method of silver nanorod / polymer / silver nanosheet core-shell nanomaterial comprises the following steps:

[0061] 1. Mix 1.5 mg of chloroauric acid, 2.205 mg of sodium citrate and 0.1701 mg of sodium borohydride in 28.95 ml of deionized water, mix and stir for 10 minutes and then let it stand for 2 hours to obtain an aqueous solution of gold seeds; mix 8.76 grams of CTAB and 48 mg of gold chloride acid, 4.08 milligrams of silver nitrate, 33.78 milligrams of ascorbic acid, 3.99 milliliters of hydrochloric acid and 1.2 milliliters of the above-mentioned gold seed solution were mixed and stirred in 255 milliliters of deionized water for 1 minute and then left still for 12 hours to obtain the gold nano-bicones; Nano biconical, 18.42g of CTAC, 244.8mg of silver nitrate and 1267.2mg of ascorbic acid were dissolved in 1200ml of deionized water, mixed and stirred evenly, heated at 60°C for 4 hours and centrifuged to collect the precipitate to obtain silver nanoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com