Preparation method and application of a weakly water-soluble loaded phosphotungstic heteropoly acid

A phosphotungstic heteropolyacid, water-soluble technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of increasing unsafe hidden dangers and endangering human health , easy-to-corrosion equipment and other problems, to avoid production safety problems, help the protection of the environment, and improve the effect of production safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

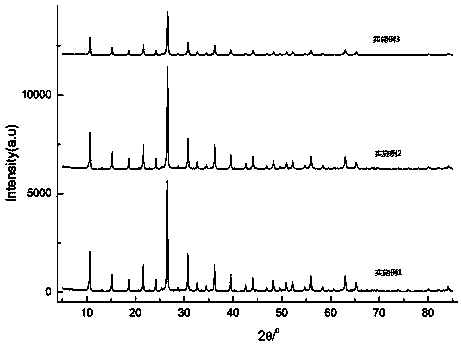

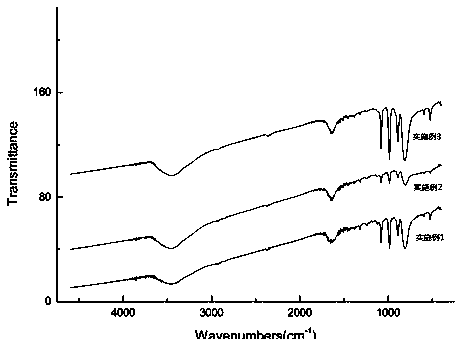

Embodiment 1

[0024] (1) Generation of active tungstic acid

[0025] First weigh sodium tungstate (Na 2 WO 4 2H 2 O) Dissolved in water to obtain sodium tungstate aqueous solution, water volume (ml) and Na 2 WO 4The mass (g) ratio is 10:1, transfer it to a separatory funnel, and set aside; then measure 0.8mol / L HCl solution in a beaker, and the volume of HCl (ml) and Na 2 WO 4 The mass (g) ratio is 10:1; then the sodium tungstate aqueous solution is added dropwise to the HCl solution at a uniform speed to obtain a yellow-green precipitate, and stirred; after the sodium tungstate is completely added dropwise, continue to stir for 40 minutes, deposit for 2 hours, and suction filter to obtain a yellow-green precipitate. The green solid is tungstic acid.

[0026] (2) Preparation of water-soluble phosphotungstic heteropolyacid

[0027] After step (1) is completed, first follow H 3 PO 4 Volume (ml) and Na 2 WO 4 The mass (g) ratio is 15:1, measure dilute H with a concentration of 0.12m...

Embodiment 2

[0034] A preparation method of a solid heteropolyacid that catalyzes and strengthens the degradation of perilla stalks, the same as in Example 1, wherein:

[0035] In step (1), the volume of water (ml) and Na 2 WO 4 The ratio of mass (g) is 8:1, the concentration of HCl is 0.7mol / L, the volume of HCl (ml) and Na 2 WO 4 The mass (g) ratio is 8:1, the stirring time is 50min, and the deposition is 2.5h.

[0036] In step (2), H 3 PO 4 Volume (ml) and Na 2 WO 4 The mass (g) ratio is 10:1, H 3 PO 4 The concentration is 0.13mol / L, and the stirring time is 50min.

[0037] In step (3), the mass (g) of citric acid is 25% of the mass (g) of sodium tungstate, the mass (g) of the loading matrix is 5% of the mass (g) of sodium tungstate, the stirring time is 50min, and the mass of KCl The mass (g) is 8% of the mass (g) of sodium tungstate, and the yield of supported TS-1 phosphotungstic heteropoly acid is 74.48%.

[0038] In step (4), the number of perilla stalks selected is 20...

Embodiment 3

[0041] A preparation method of a solid heteropolyacid that catalyzes and strengthens the degradation of perilla stalks, the same as in Example 1, wherein:

[0042] In step (1), the volume of water (ml) and Na 2 WO 4 The ratio of mass (g) is 15:1, the concentration of HCl is 0.9mol / L, the volume of HCl (ml) and Na 2 WO 4 The mass (g) ratio is 15:1, the stirring time is 60min, and the deposition is 3h.

[0043] In step (2), H 3 PO 4 Volume (ml) and Na 2 WO 4 The mass (g) ratio is 20:1, H 3 PO 4 The concentration is 0.11mol / L, and the stirring time is 60min.

[0044] In step (3), the mass (g) of citric acid is 15% of the mass (g) of sodium tungstate, the mass (g) of the loading matrix is 30% of the mass (g) of sodium tungstate, the stirring time is 30min, and the mass of KCl The mass (g) is 12% of the mass (g) of sodium tungstate, and the yield of supported TS-1 phosphotungstic heteropoly acid is 67.09%.

[0045] In step (4), the number of perilla stalks is 40-60 mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com