Pulse bag dust collector

A bag filter and pulse technology, applied in the field of pulse bag filter, can solve the problems of large filter bag load, uneven air intake, increased filter bag wear and damage probability, etc., so as to reduce energy consumption and reduce dust content. , The effect of reducing the frequency of replacing individual filter bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

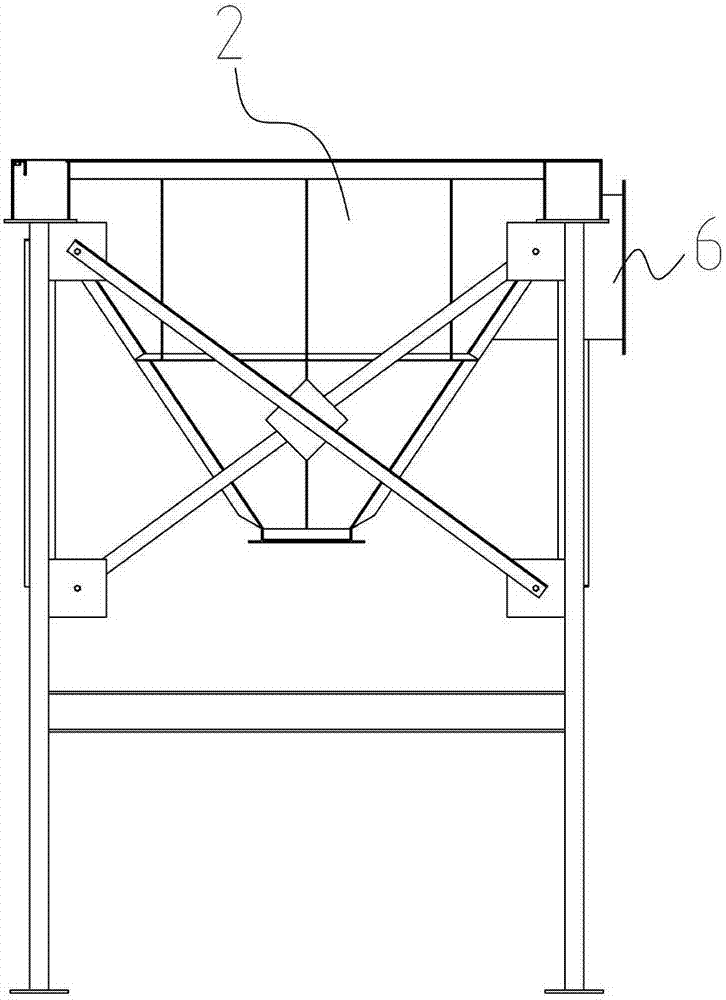

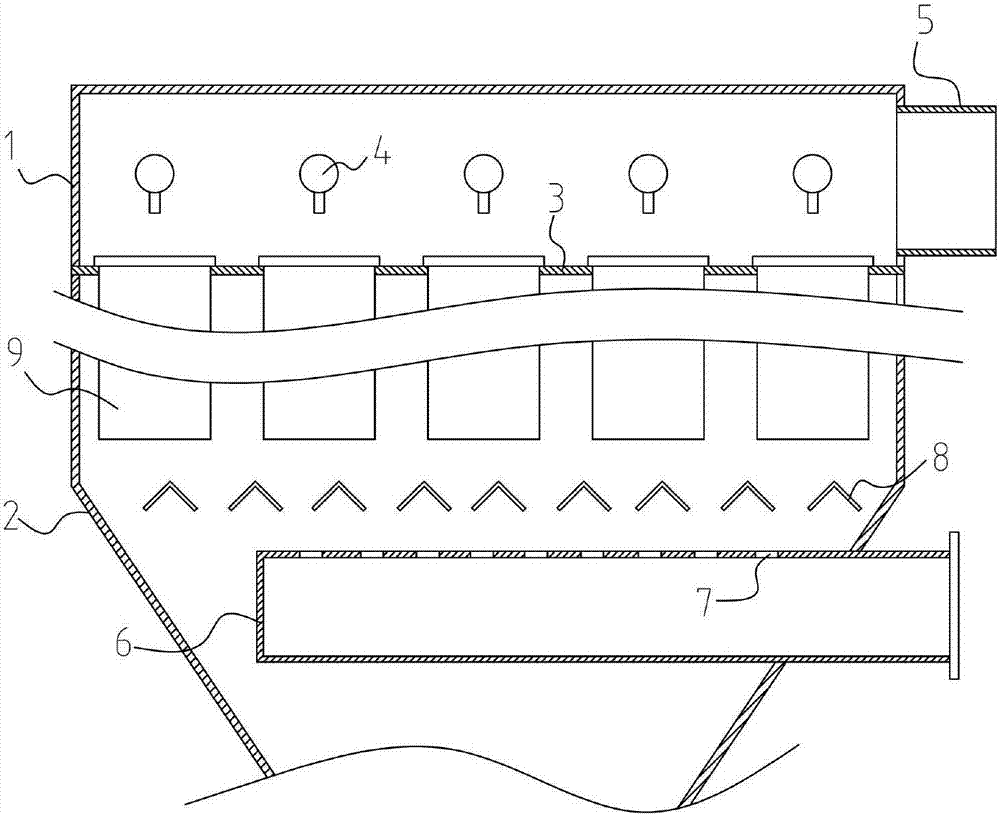

[0016] When the present invention installs the first kind of turbulence device, as Figures 1 to 4 As shown, a pulse bag type dust collector includes a housing 1, an ash hopper 2 communicating with the housing 1 is fixedly connected under the housing 1, an air inlet pipe 6 passes through the outer wall of the ash hopper 2, and one end Extending into the ash hopper 2, a plurality of air inlet holes 7 are evenly distributed on the end surface of the air inlet pipe 6 facing the housing 1, and a partition 3 is also provided in the housing 1, and the partition 3 separates the housing 1 is divided into two independent cavities, the upper cavity communicates with an exhaust pipe 5, a plurality of through holes are evenly distributed on the partition 3, and a filter bag 9 is installed on each through hole , above each through hole, a blowing pipe with a blowing direction towards the filter bag 9 is arranged, and a plurality of turbulence devices are installed in the ash hopper 2 betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com