Simulation cable for cable accessory test and method for testing cable accessories

A technology for simulating cables and cable accessories, applied in electrical components, insulated cables, cables, etc., can solve the problems of difficult installation, scrapped accessories, difficult to take out, etc., to achieve excellent electrical performance, meet use requirements, and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be further described in detail below.

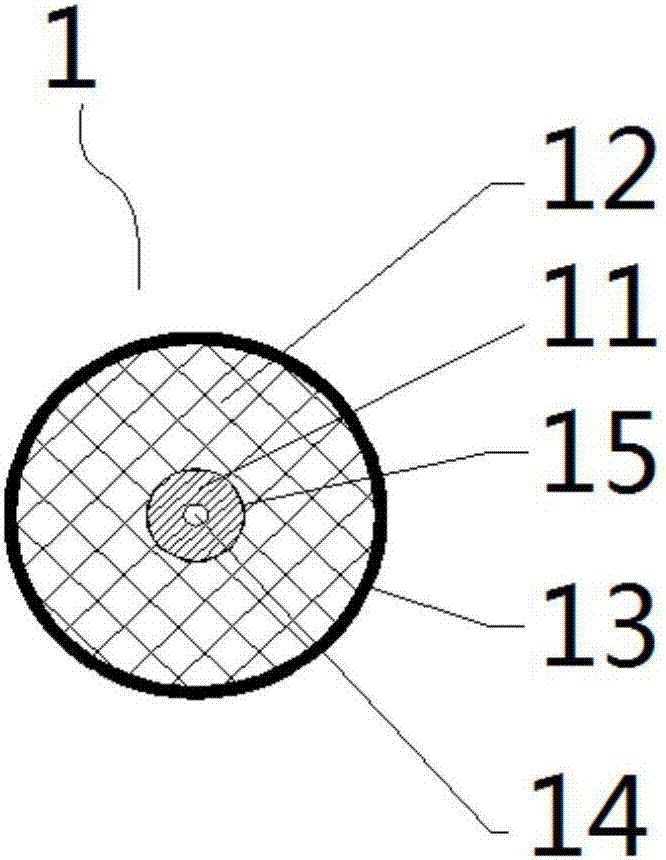

[0029] like Figure 1 to Figure 5 Shown, a kind of dummy cable for cable accessory test, it comprises dummy cable body 1, and described dummy cable body 1 comprises conductor 11, insulation protective layer 12 and shielding layer 13 sequentially from inside to outside, and described dummy cable body A ventilation channel 14 is provided in the middle of the conductor 11 of 1;

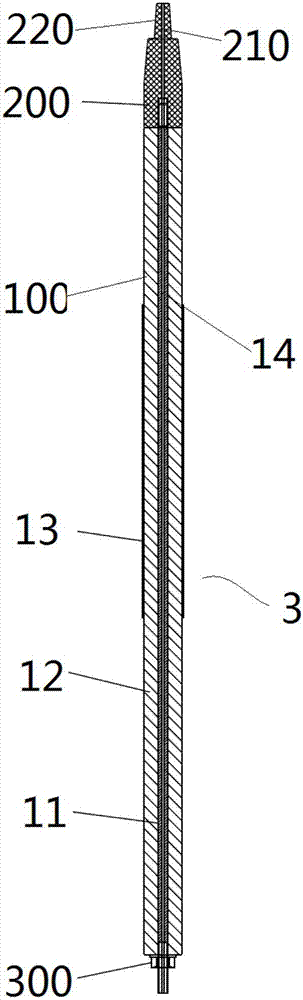

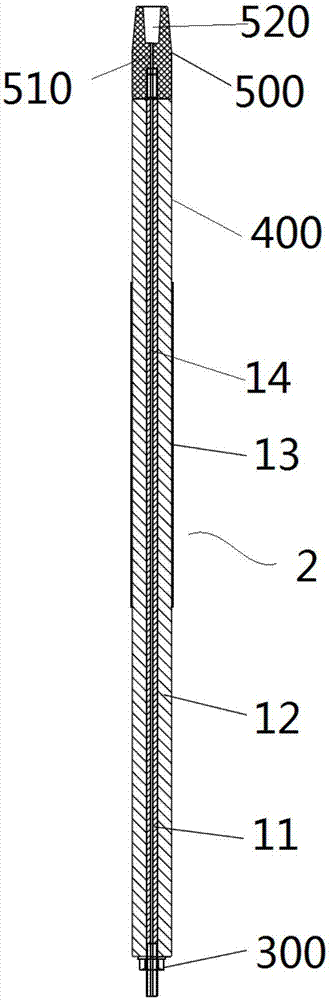

[0030] The dummy cable used for cable accessories test includes a first dummy cable member 2 and a second dummy cable member 3, the first dummy cable member 2 includes a first dummy cable body 100 and a connecting male head 200, the first dummy cable member 2 One end of the simulation cable body 100 is connected to the connection male head 200, and the other end of the first simulation cable body 100 is provided with a fixed connector 300; the second simulation cable component 3 includes a second simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com