A four-part phase stepping mirror and its manufacturing method

A technology of phase stepping and mirrors, which is applied in the field of optical components, can solve the problem of uneven surface height of the four-part film, and achieve the effects of less difficulty in evaporation, improved reflectivity, and instrument calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

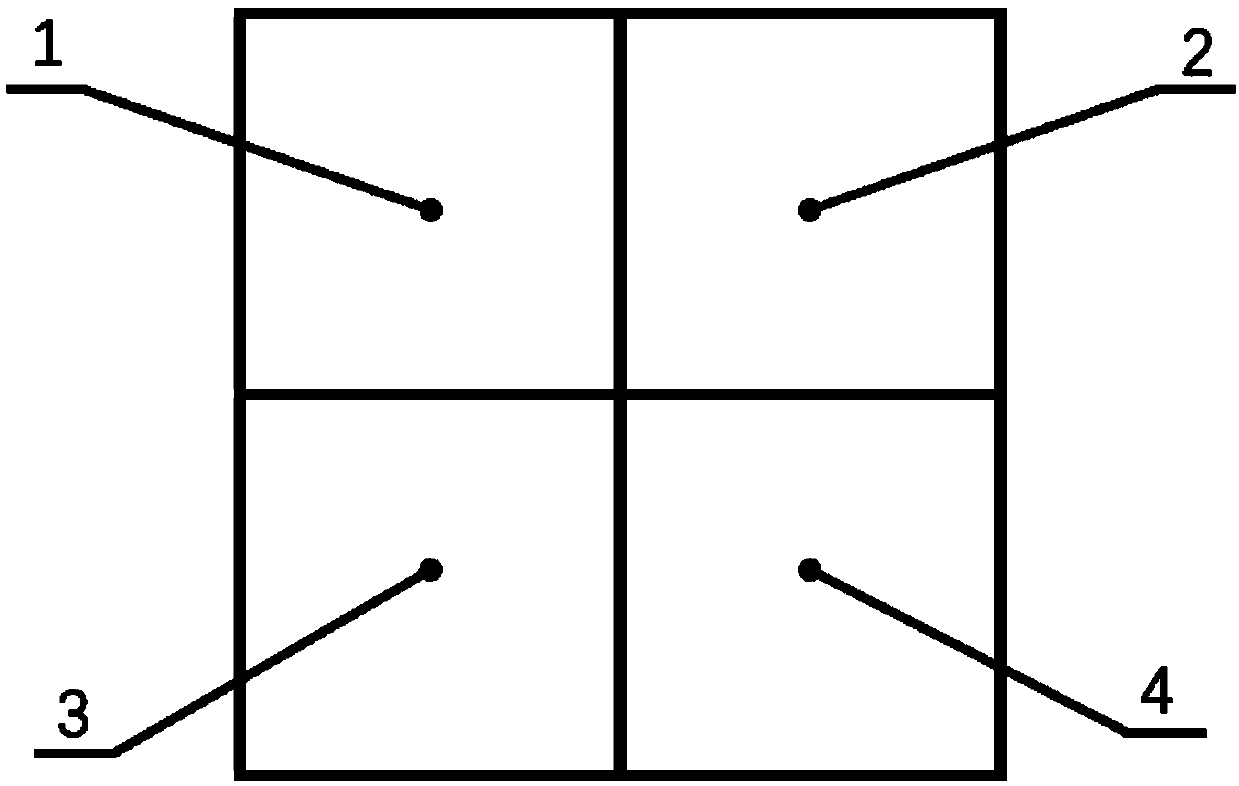

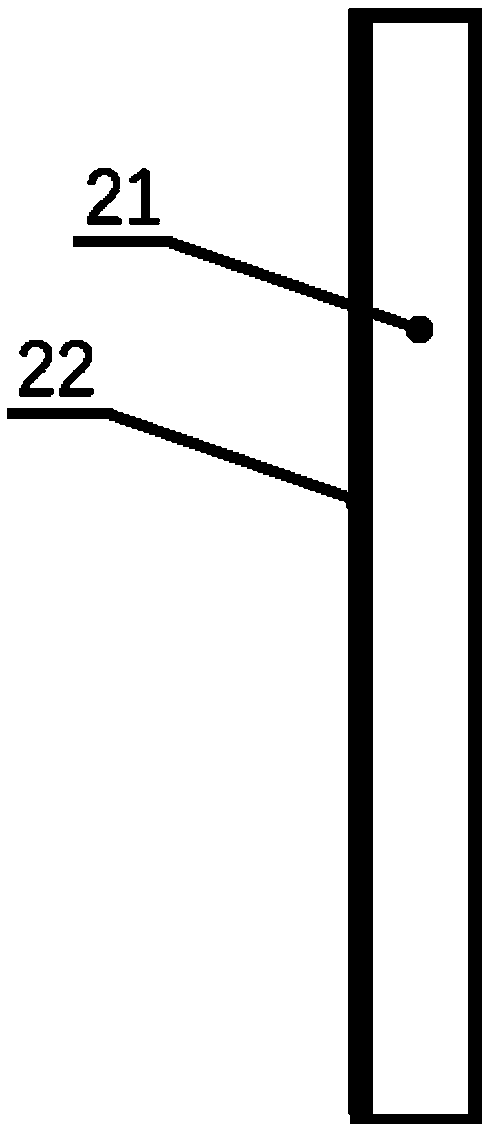

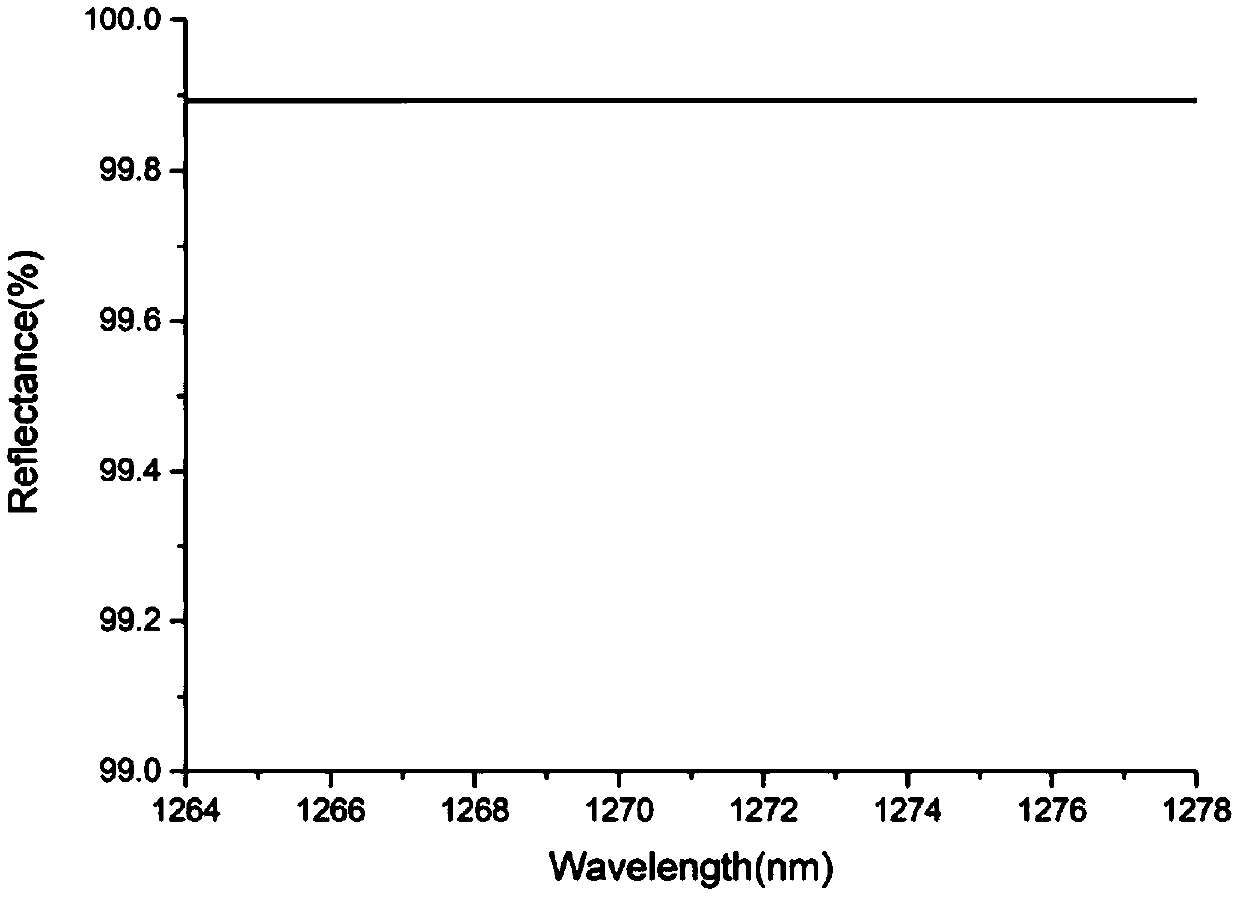

[0026] The present invention first proposes a phase stepping mirror with four divisions: a glass substrate 21 with a flat rear surface, a composite film layer 22 is coated on the rear surface of the glass substrate 21, and the glass substrate 21 is divided into A, B, C, D Four regions of equal area. The surface on which light is incident on the glass substrate 21 is the front surface, and the surface from which light is emitted is the rear surface. The composite film layer 22 has 9 layers in total, the first layer is a step phase modulation layer, the second to seventh layers are reflection enhancing layers, the eighth layer is a reflection layer, and the ninth layer is a protective layer. The first film material is MgF 2 , the second film material is TiO 2 ; The third layer of membrane material is MgF 2 ; The fourth film material is TiO 2 ; The fifth layer of film material is MgF 2 ; The sixth film material is TiO 2 ; The seventh layer of membrane material is MgF 2 ; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com