A test method for heat release rate of organic dust

A technology of heat release rate and organic dust, which is applied in the field of material heat release rate measurement and evaluation, can solve the problems of quantitative analysis of organic dust explosion hazardous combustion behavior, which has not been reported yet, the combustion performance is difficult to achieve, and the lack of characterization of organic dust, etc. To achieve the effect of improving the minimum ignition energy, the product is dense and uniform, and the impact is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a test method for the heat release rate of organic dust, the specific steps are as follows:

[0028] Step 1: select a rice husk sample, sieve out a powder with a fineness of 80-85 mesh, take 200g and place it in an oven, and dry it at 60°C for 1 hour;

[0029] Step 2, according to the density of the test sample, weigh an appropriate amount of sample and put it into pre-laid aluminum foil paper, the bottom surface is 20×20mm 2 After being pressed at 0.4MPa in a steel columnar mold, the pressure is released and demolded to obtain 2-5mm thick briquettes, and 25 samples are made;

[0030] Step 3: Encapsulate the briquette in an elastic plastic bag, seal it and put it into a high-pressure cylinder. The initial pressure is 2MPa, the pressure increase rate is 2MPa / min, and the pressure holding time is 60s; the medium pressure is 50MPa, and the pressure increase rate is 10MPa / min. The pressure holding time is 90s; the high pressure is 100MPa, the press...

Embodiment 2

[0034] This embodiment provides a test method for the heat release rate of organic dust, the specific method is as follows;

[0035] Step 1, sieving out fineness is 100~110 orders, other is the same as embodiment 1;

[0036] Step 2, add 2% starch, press at 0.2MPa, and others are the same as in Example 1;

[0037] Step three and four, with embodiment 1;

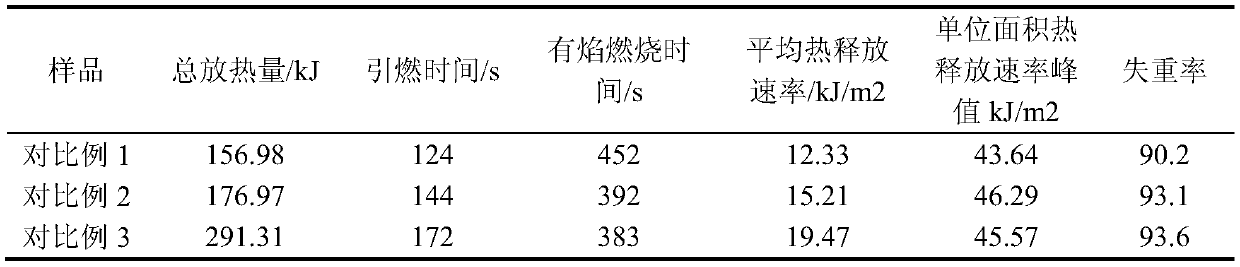

[0038] The experimental results of the heat release rate of the tested rice husks are shown in Table 1.

Embodiment 3

[0040] This embodiment provides a test method for the heat release rate of organic dust, the specific method is as follows;

[0041] Step 1, the sieving fineness is more than 120 orders, and others are the same as in Example 1;

[0042] Steps two to four are the same as in Example 1. The experimental results of the heat release rate of the tested rice husks are shown in Table 1.

[0043] The heat release rate of different fineness sample embodiment of table 1

[0044]

[0045] It can be seen from Table 1 that the heat release rate of organic powders with different finenesses can be successfully measured by this method, and the heat release performance of the samples treated by isostatic pressing is stable, which is shown as the change of ignition time and flaming combustion time , but the total heat release, peak heat release rate per unit area, and average heat release rate of samples with different finenesses are relatively close.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com