Four-quadrant hydraulic loading system

A hydraulic loading, four-quadrant technology, used in fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc. Pressure rise and other problems to achieve the effect of reducing rated flow, avoiding pressure overshoot and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

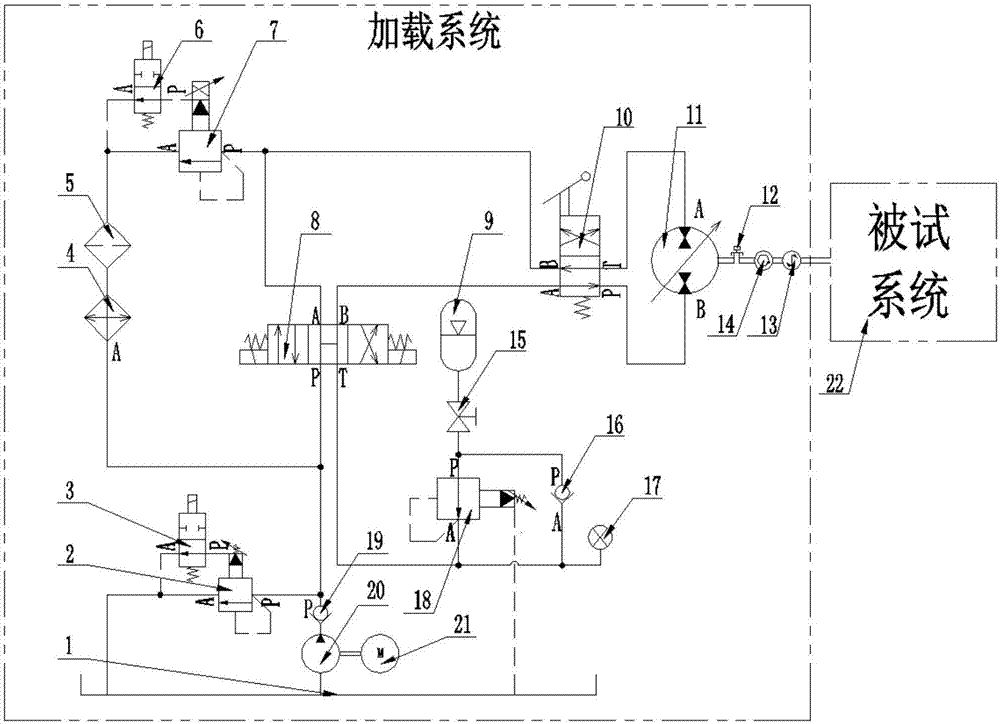

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, a four-quadrant hydraulic loading system includes a variable hydraulic pump / motor 11, a manual reversing valve 10, a three-position four-way electromagnetic reversing valve 8, a pilot-operated proportional electromagnetic relief valve 7, and a pilot-operated pressure reducing valve 18;

[0028] The variable hydraulic pump / motor 11 is driven by the system under test 22 through the clutch 12, its A port is connected to the T port of the manual reversing valve 10, and its B port is connected to the P port of the manual reversing valve 10;

[0029] Port A of the manual reversing valve 10 is connected to port B of the three-position four-way electromagnetic reversing valve 8, and its B port is simultaneously connected to port A of the three-position four-way electromagnetic reversing valve 8 and the pilot proporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com