Sealing structure capable of achieving bearing cavity-sharing and bearing external cavity pressure equalizing

A bearing and common cavity technology, which is applied in the field of ground gas turbines and aeroengines, can solve problems such as unsatisfactory operation, long air system flow paths, and complex structures, and achieve convenient adjustment of lubricating oil flow, high operating reliability, and simplified flow. road effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

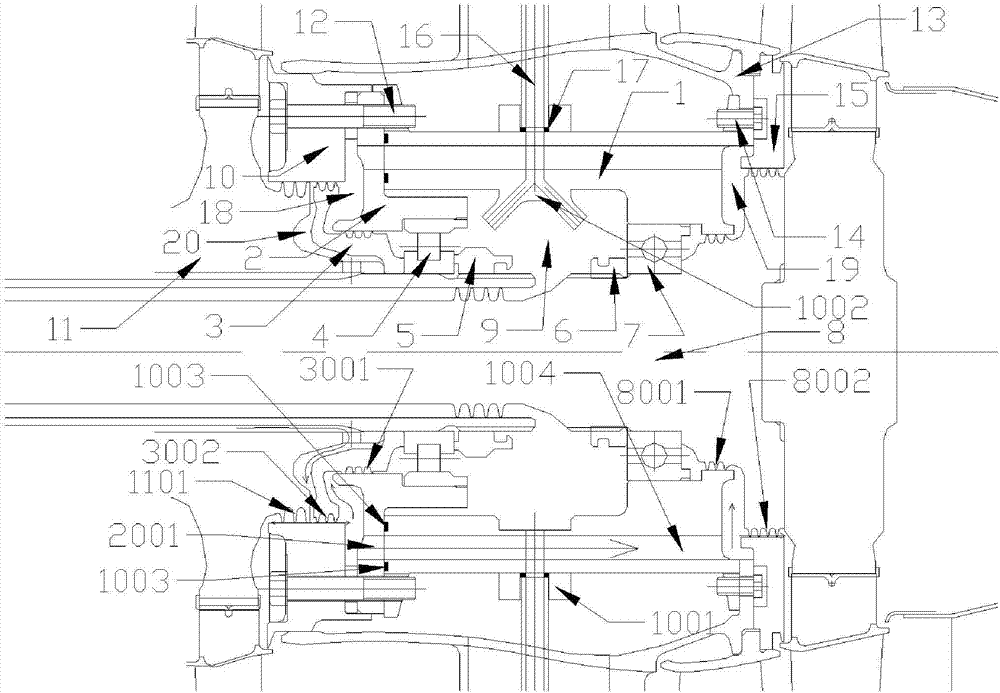

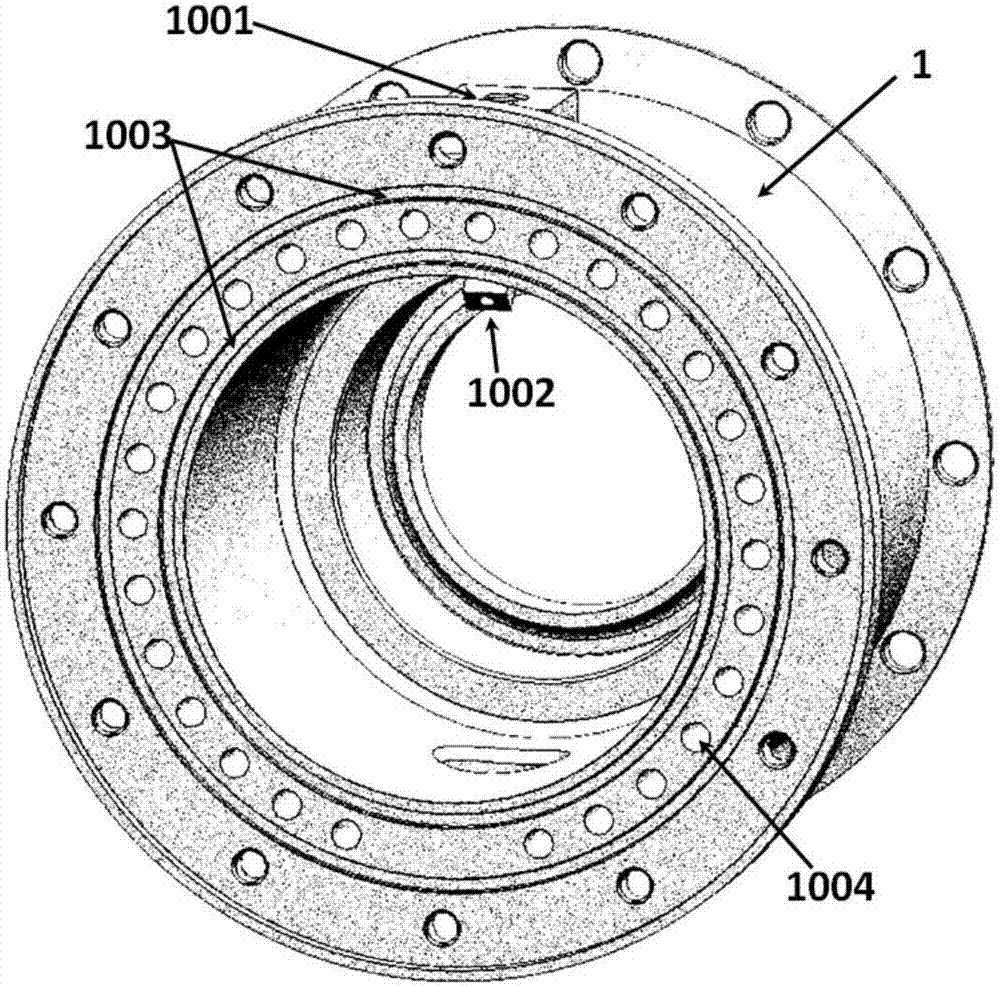

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0035] During the operation of the engine, it is necessary to lubricate and cool the two bearings rotating at high speed. During this process, the lubricating oil takes away the heat of the bearings and the impurities generated by friction, and part of the lubricating oil becomes an oil mist state, so the bearing cavity The oil is filled with liquid lubricating oil and oil mist, and flows into the lubricating oil return line through the oil return hole on the rear bearing seat to realize the collection and return of lubricating oil. In order to prevent the lubricating oil in the bearing cavity from leaking, it needs to be sealed tightly. Although the effect of contact sealing is the best, it cannot be widely promoted in engines due to the current techni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com