Guiding and positioning device of pre-embedded grouting drilling on needle girder trolley

A technology of guiding and positioning, needle beam platform, applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of increased construction cost, increased labor cost, long construction time, etc., to reduce quality defects and improve one-time cost. The effect of reducing the porosity and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

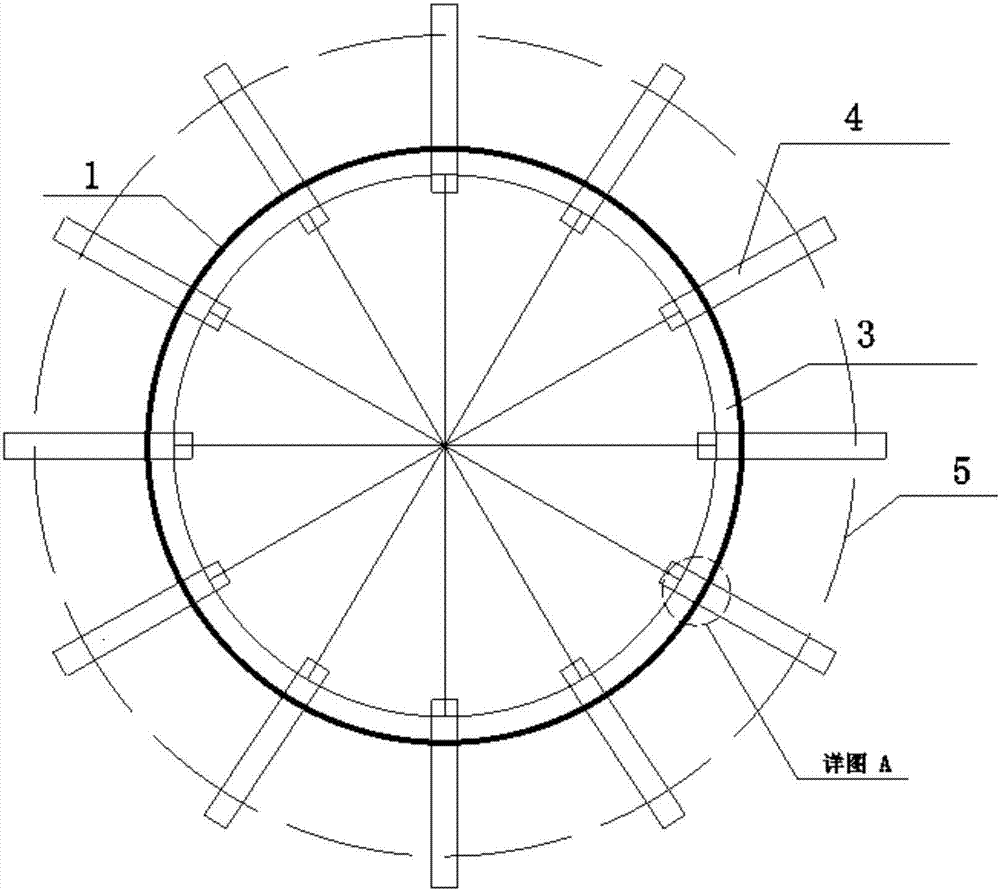

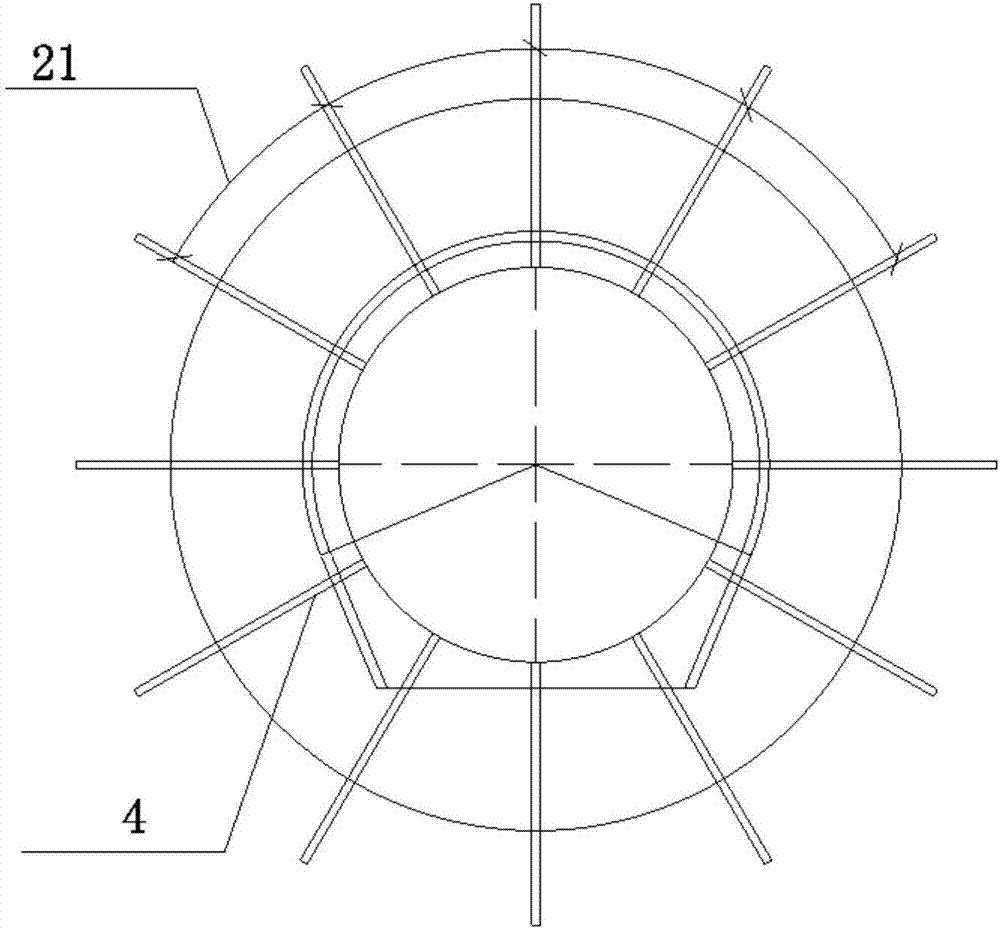

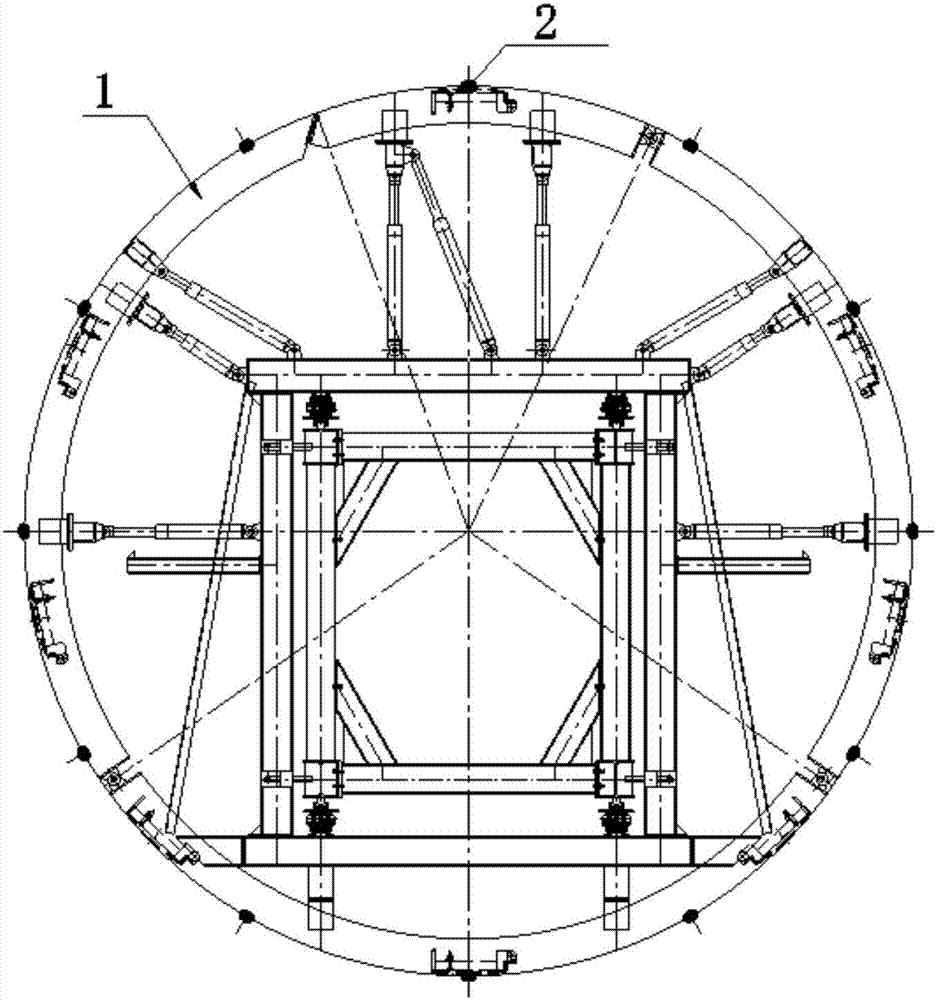

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, a guiding and positioning device for pre-embedded grouting drilling on a needle beam trolley includes a trolley formwork 3 and a pre-embedded grouting casing 4; the trolley formwork 3 is provided with a grouting hole 2 according to the grouting position, and the corresponding shotcrete A pre-buried hole is drilled in advance on the surface 5; the front end of the pre-buried grouting casing 4 passes through the grouting hole 2 of the construction site to be grouted, and is vertically inserted into the pre-buried hole, and the tail end of the grouting casing is left exposed outside the trolley template 3 Part 42 ; the pipe end of the exposed part 42 of the grouting casing is sealed by the sealing plate 6 . There is a sealing plug 9 in the grouting hole 2 of the grouting construction site.

[0034] Each pre-emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com