Preparation method for Pt-Zr modified aluminide coating

A technology of aluminide and coating, which is applied in the direction of coating, metal material coating process, electrolytic coating, etc., can solve the problems that the Zr layer is not easy to disperse, popularize and apply, and not easy to deposit, so as to achieve uniform distribution and controllable coating Strong resistance and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

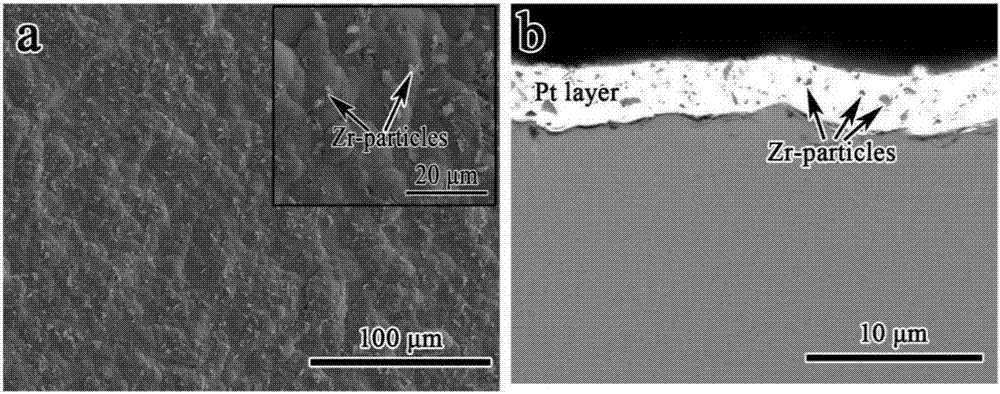

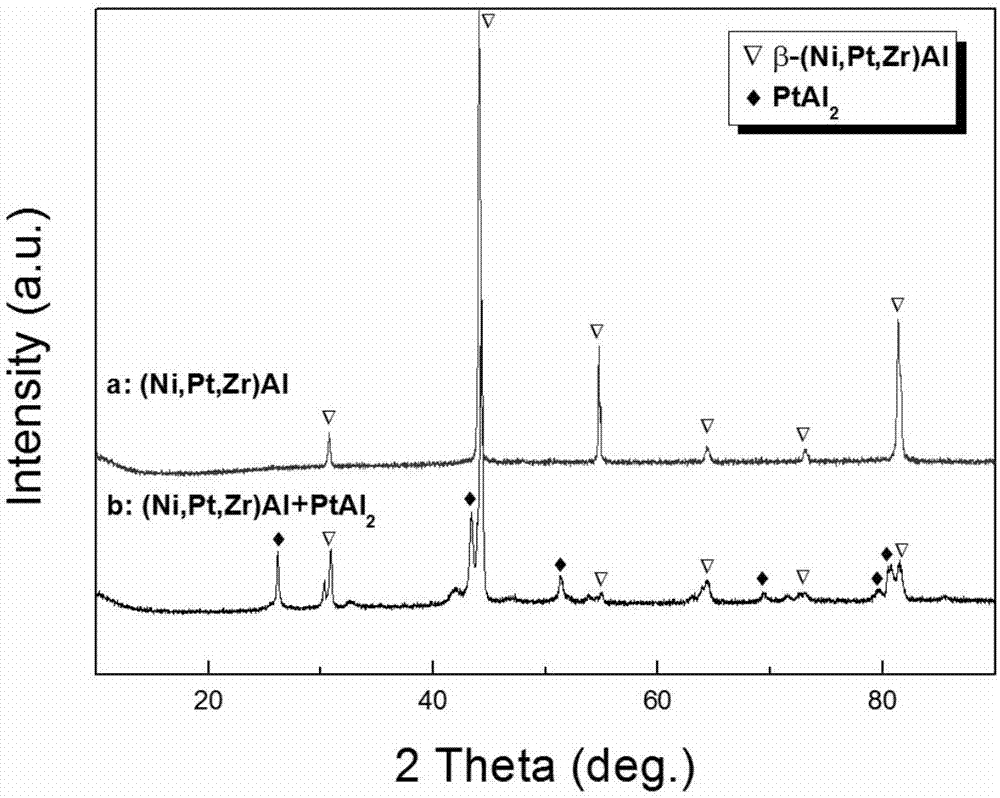

[0032] Preparation method of Zr-modified β-(Ni,Pt)Al single-phase coating

[0033] After sandblasting the matrix alloy, carry out two-step degreasing treatment: the first step is ultrasonic cleaning with acetone for 15-30min, the second step is boiling in 40-60g / L NaOH solution for 10min; after degreasing, the sample is placed in a Electroplating is carried out in the Pt plating solution of Zr particles. During electroplating, the temperature of the plating solution is kept in the range of 40°C-60°C, the pH value is between 1.0-3.0, and the current density during electroplating is 4-20mA / cm 2. The Zr particles are evenly suspended in the plating solution, and the particle size of the Zr particles is 0.1-10 μm. In order to keep the Zr particles in a suspended state, stir with a magnetic stirrer at a stirring speed of 10-30r / min. When the thickness of the coating is greater than 5 μm, take out the sample, ultrasonically clean the Zr particles remaining on the surface of the sa...

Embodiment 2

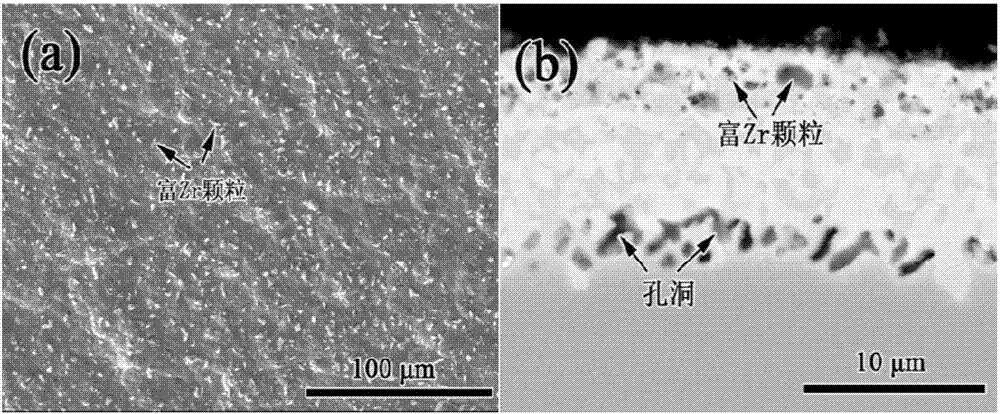

[0038] Zr modified PtAl 2 Preparation method of +β-(Ni,Pt)Al dual-phase coating

[0039] After surface treatment of the base alloy, a composite coating of 5 μm to 8 μm is electroplated according to the method described in Example 1. The samples after electroplating were ultrasonically cleaned to remove residual Zr particles on the surface.

[0040] Aluminizing is carried out by vapor phase aluminizing. Before aluminizing, clean the sample ultrasonically in ethanol for 5-10 minutes, and after drying, hang the sample at a position 5-10 cm above the infiltrating agent. Penetration agent consists of Fe-Al powder and active agent NH 4 Cl composition, wherein the Al content is about 51wt.%. The aluminizing method with high temperature and low activity is adopted, the aluminizing temperature is 1060°C, and the holding time is 5h. During the aluminizing process, Ar gas is filled as a protective gas. After the heat preservation is completed, it is cooled to room temperature with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com