Zinc powder sherardizing method enabling thickness of zinc coat to be considerable and uniform

A technology of powder sherardizing and layer thickness, applied in the field of powder sherardizing, can solve the problems of small thickness of sherardizing layer, slow seepage speed, low activity of zinc sherardizing agent, etc. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation method of described powder zinc sherardizing agent, comprises the following steps:

[0063] S1: Weigh 120-200 parts of zinc powder, 7-12 parts of zeolite powder, 5-7 parts of aluminum chloride powder, 2-4 parts of aluminum oxide powder, 4-6 parts of aluminum sulfate powder and cobalt oxide powder in parts by weight 2.2-3.8 parts, 1.6-2.5 parts of lead powder, 1.5-2.3 parts of magnesium stearate powder, 1.2-2 parts of sodium borate powder, 1.5-2.3 parts of calcium silicate powder, 0.4-0.8 parts of graphene powder, surfactant 0.4-0.7 parts, 0.5-0.8 parts of dispersing agent, 0.7-1 parts of regulator, 1.3-1.8 parts of activator, 0.8-1.2 parts of diffusing agent, 0.4-0.6 parts of strengthening agent, 0.3-0.5 parts of chelating agent, and penetrating agent 1-1.5 parts, 0.6-1 parts of stabilizer;

[0064] S2: the zinc powder, zeolite powder, aluminum chloride powder, aluminum oxide powder, aluminum sulfate powder, cobalt oxide powder, lead powder, magnesium s...

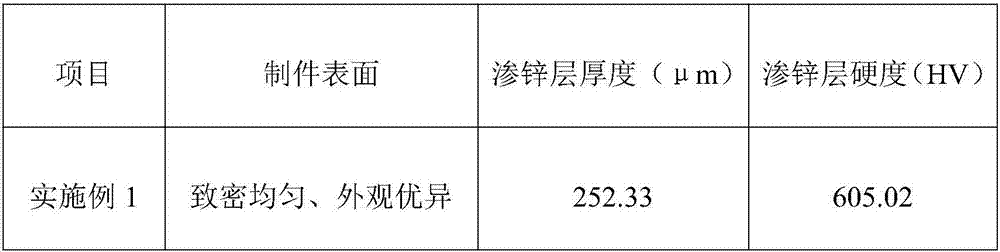

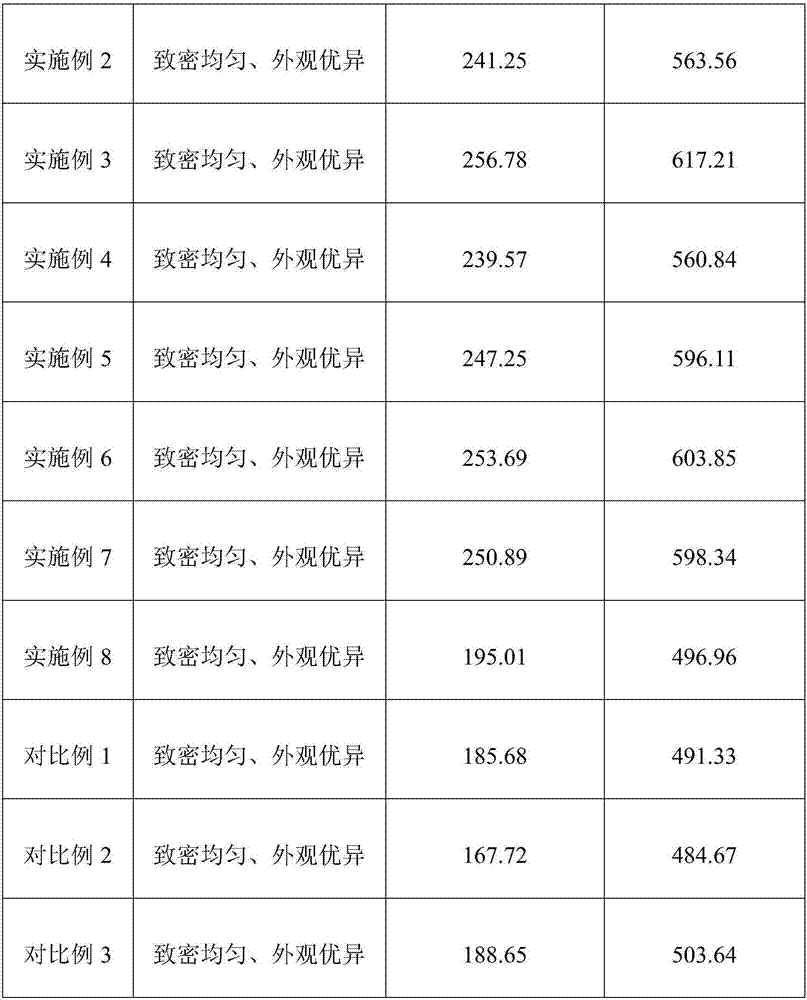

Embodiment 1

[0069] A method of powder sherardizing with considerable and uniform thickness of sherardizing layer, including sandblasting, boxing, powder mixing, sherardizing, centrifugal zinc dumping, cooling, selection, packaging, powder sherardizing agent used in sherardizing, and The unit is parts by weight, including the following raw materials: 165 parts of zinc powder, 10 parts of zeolite powder, 6 parts of aluminum chloride powder, 3 parts of aluminum oxide powder, 5 parts of aluminum sulfate powder, 3 parts of cobalt oxide powder, 2 parts of lead powder, hard 2 parts of magnesium fatty acid powder, 1.6 parts of sodium borate powder, 2 parts of calcium silicate powder, 0.6 part of graphene powder, 0.6 part of surfactant, 0.7 part of dispersant, 0.85 part of regulator, 1.6 part of activator, 1 part of diffusing agent part, 0.5 part of strengthening agent, 0.4 part of chelating agent, 1.2 part of penetrating agent, and 0.8 part of stabilizer.

[0070] The particle size of the zinc po...

Embodiment 2

[0096] A method of powder sherardizing with considerable and uniform thickness of sherardizing layer, including sandblasting, boxing, powder mixing, sherardizing, centrifugal zinc dumping, cooling, selection, packaging, powder sherardizing agent used in sherardizing, and The unit is parts by weight, including the following raw materials: 122 parts of zinc powder, 7 parts of zeolite powder, 5 parts of aluminum chloride powder, 2 parts of aluminum oxide powder, 4 parts of aluminum sulfate powder, 2.2 parts of cobalt oxide powder, 1.6 parts of lead powder, hard 1.5 parts of magnesium fatty acid powder, 1.2 parts of sodium borate powder, 1.5 parts of calcium silicate powder, 0.4 parts of graphene powder, 0.4 parts of surfactant, 0.5 parts of dispersant, 0.7 parts of regulator, 1.3 parts of activator, and 0.8 parts of diffusing agent part, 0.4 part of strengthening agent, 0.3 part of chelating agent, 1 part of penetrating agent, and 0.6 part of stabilizer.

[0097] The particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com