Method for sulfur-free clarification of clear juice

A clear juice and clear liquid technology, which is applied in the field of refined sugar, can solve the problems of low removal rate of non-sugar components, large consumption of clarifiers, and impact on sugar safety, so as to facilitate hydrolysis reaction, shorten the duration of enzymatic hydrolysis process, and achieve good decolorization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

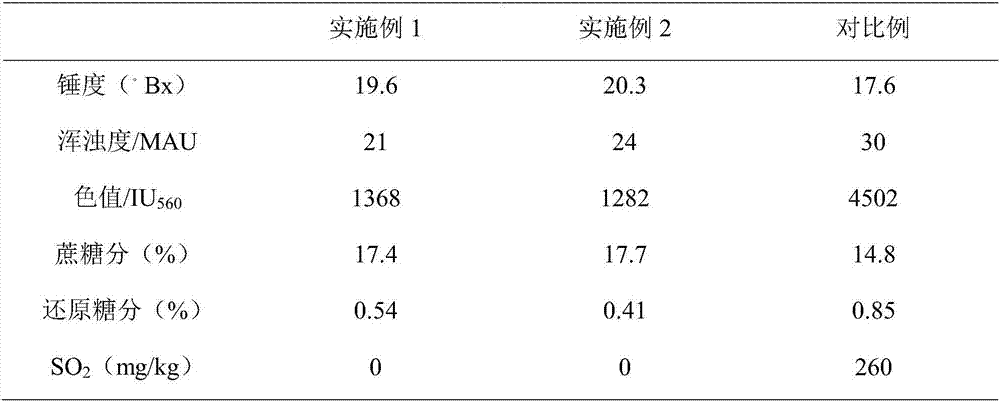

Examples

Embodiment 1

[0024] A method for clarifying juice without sulfur, comprising the following steps:

[0025] Step 1. Squeeze and filter sugarcane to obtain bagasse and sugarcane juice. Add phosphoric acid to the sugarcane juice under stirring to make the concentration of phosphoric acid reach 200 mg of phosphoric acid per L of sugarcane juice. At the same time, add milk of lime until the pH is 7-8, and heat to boiling, sedimentation and separation to obtain clarified juice;

[0026] Step 2. Transfer the bagasse to a temperature of 100°C and a steam pressure of 1-2 MPa for steam explosion. The steam explosion time is less than 0.01s, and the pressure holding time is 1min. After that, the pressure is released to normal pressure every 15s. The total weight of the bagasse released to normal pressure for the first time is 25%, and the bagasse after steam explosion is collected;

[0027] Step 3: Spray the compound enzyme solution on the surface of the bagasse after steam explosion, soak the surfa...

Embodiment 2

[0032] A method for clarifying juice without sulfur, comprising the following steps:

[0033] Step 1. Squeeze and filter sugarcane to obtain bagasse and sugarcane juice. Add phosphoric acid to the sugarcane juice under stirring to make the concentration of phosphoric acid reach 200 mg of phosphoric acid per L of sugarcane juice. At the same time, add milk of lime until the pH is 7-8, and heat to boiling, sedimentation and separation to obtain clarified juice;

[0034] Step 2. Transfer the bagasse to a temperature of 100°C and a steam pressure of 1-2 MPa for steam explosion. The steam explosion time is less than 0.01s, and the pressure holding time is 1min. After that, the pressure is released to normal pressure every 15s. The total weight of the bagasse released to normal pressure for the first time is 25%, and the bagasse after steam explosion is collected;

[0035] Step 3, soak the bagasse after steam explosion in ethanol solution for 6 hours, the concentration of ethanol s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com