New process for preparing cytisine

A technology of cytisine and a new process, which is applied in the field of preparation of cytisine, can solve the problems of large loss and consumption, difficult handling of solvents, etc., and achieve the effects of less loss, high yield and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

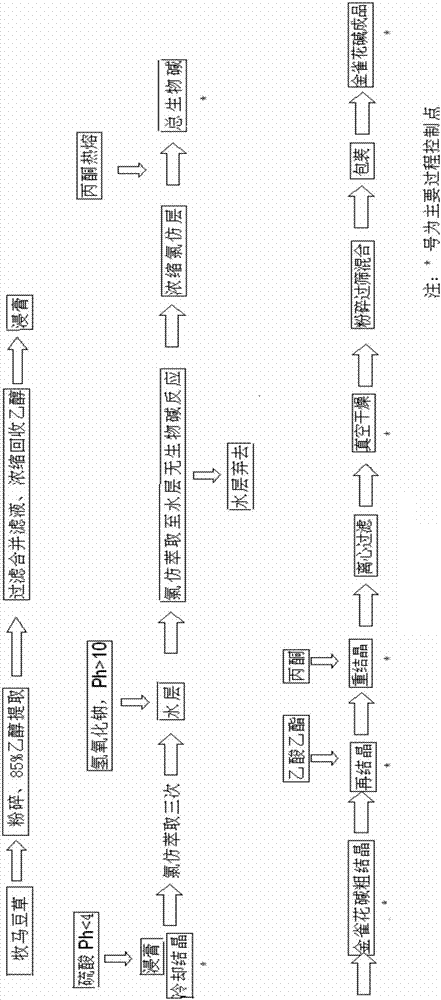

Image

Examples

Embodiment 1

[0014] Embodiment 1, a kind of new technique for preparing cytisine, such as figure 1 shown, including the following steps

[0015] ① Grinding the raw material, edamame grass, soaking and extracting with ethanol, filtering and combining the filtrates, and concentrating the filtrates to obtain extracts.

[0016] ②Primary extraction: Transfer the extract to an extraction tank, adjust the pH to <4 with sulfuric acid, add chloroform to the extraction tank, and stir for extraction. The chloroform layer was separated, and the same method was operated three times, the water layer was collected, and the chloroform was recovered.

[0017] ③Secondary extraction: the water layer extract was adjusted to pH > 10 with sodium hydroxide solution to free cytisine, and then extracted with chloroform until the water layer had no alkaloid reaction, and the water layer was discarded.

[0018] ④ Concentrating the chloroform layer to obtain the total alkaloids, dissolving them in acetone, cooling,...

Embodiment 2

[0021] Embodiment 2, a kind of new process for preparing cytisine, comprises the following steps

[0022] ①Take 500kg of crushed herb and 6000L of 85% ethanol and soak for 24 hours. They were extracted three times at a temperature of 80° C., and the combined filtrates were filtered. The filtrate was recovered under the condition of temperature 80°C and vacuum degree of -0.050~-0.070MPa to obtain 200kg of extract.

[0023] ②Primary extraction: add the extract to the extraction tank, and adjust the pH to <4 with sulfuric acid. Add chloroform to extract at a ratio of 3:1 between chloroform and extract for 2-3 times to remove all organic impurities, separate the chloroform layer and recover chloroform at a temperature of 80°C.

[0024] ③Secondary extraction: the aqueous layer was adjusted to pH>10 with sodium hydroxide solution to free cytisine, and then extracted with chloroform until the aqueous layer had no alkaloid reaction, and the aqueous layer was discarded.

[0025] ④ C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com