Quick-drying aqueous composite anti-seepage interface material

A technology of composite anti-seepage and interface materials, which is applied in the field of fast-drying water-based composite anti-seepage interface materials, can solve the problems of restricting the application of concrete and related products, cracking and hollowing between the plastering mortar layer and the concrete base, and achieve the prevention of voids. Drumming and shedding, good hardness and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

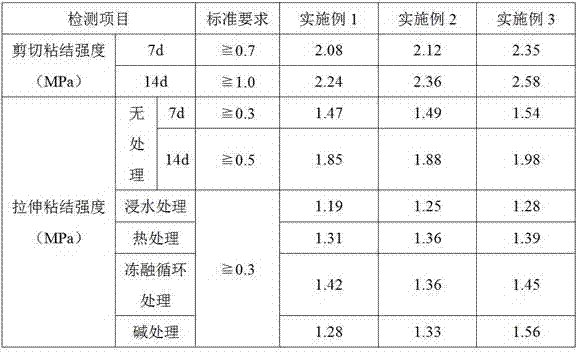

Embodiment 1

[0010] A quick-drying water-based composite anti-seepage interface material. The raw materials include: 90 parts of aluminate cement, 4 parts of water-based emulsion, 0.3 parts of polycarboxylate superplasticizer, 0.9 parts of polyvinyl alcohol powder, and three parts by weight. 0.018 parts of ethanolamine and 0.9 parts of polyoxypropylene monohydric alcohol.

[0011] The material is prepared according to the parts by weight of the above components, and water is added for dilution when used. Under the construction environment of 15°C, apply the diluted interface material evenly on the base to be constructed by brushing. The interface material is coated once, the amount of single pass is 0.15 kg / square meter, and the surface drying time is 20 minutes.

Embodiment 2

[0013] A quick-drying water-based composite anti-seepage interface material. The raw materials include: 100 parts of aluminate cement, 6 parts of water-based emulsion, 0.4 parts of polycarboxylate superplasticizer, 1 part of polyvinyl alcohol powder, and three parts by weight. 0.02 part of ethanolamine and 1 part of polyoxypropylene monohydric alcohol.

[0014] The material is prepared according to the parts by weight of the above components, and water is added for dilution when used. Under the construction environment of 15°C, apply the diluted interface material evenly on the base to be constructed by brushing. The interface material is coated once, the amount of single pass is 0.1 kg / square meter, and the surface drying time is 17 minutes.

Embodiment 3

[0016] A quick-drying water-based composite anti-seepage interface material. The raw materials include: 95 parts of aluminate cement, 5 parts of water-based emulsion, 0.35 parts of polycarboxylate superplasticizer, 0.95 parts of polyvinyl alcohol powder, and three parts by weight. 0.019 parts of ethanolamine and 0.95 parts of polyoxypropylene monohydric alcohol.

[0017] The material is prepared according to the parts by weight of the above components, and water is added for dilution when used. Under the construction environment of 15°C, apply the diluted interface material evenly on the base to be constructed by brushing. The interface material is coated once, the amount of single pass is 0.15 kg / square meter, and the surface drying time is 18 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com