Clamping device for bolt locking

A clamping device and screw technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of easy deviation of screws, reduce the probability of deviation, ensure smooth completion, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

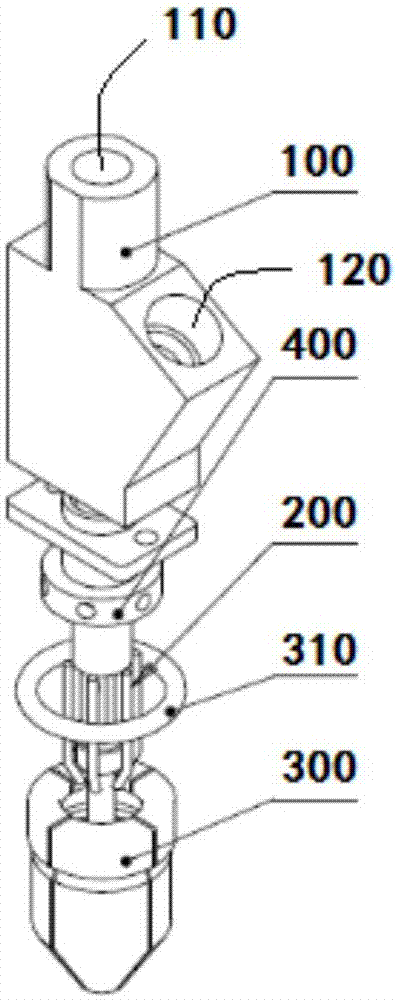

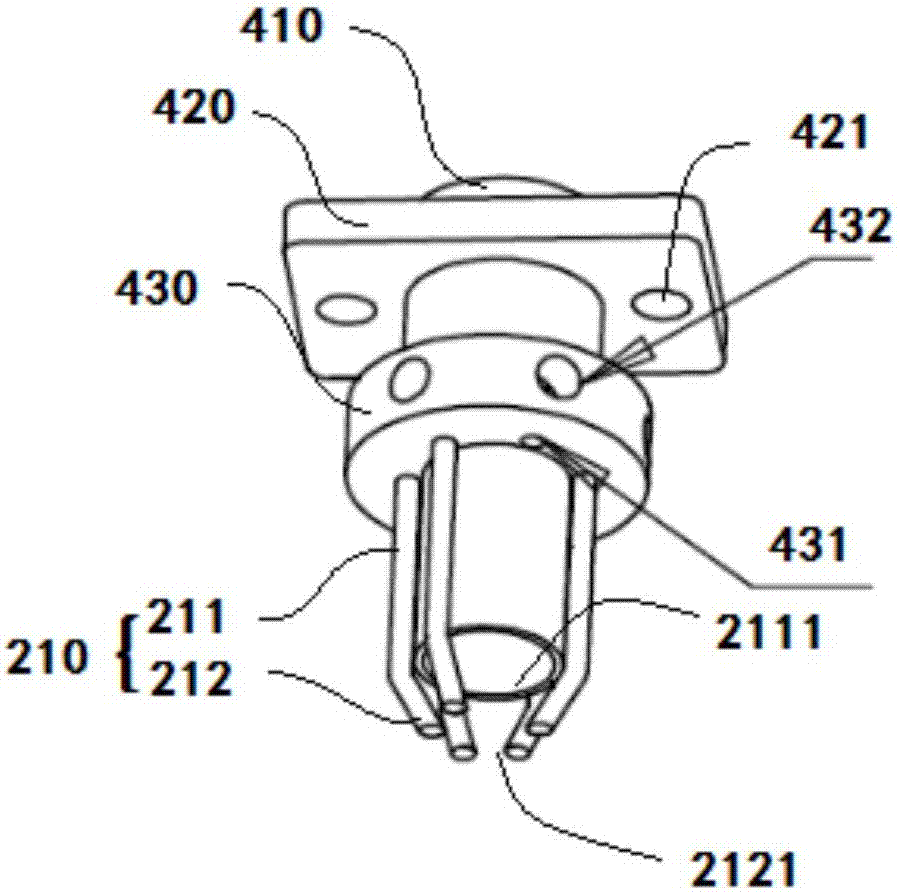

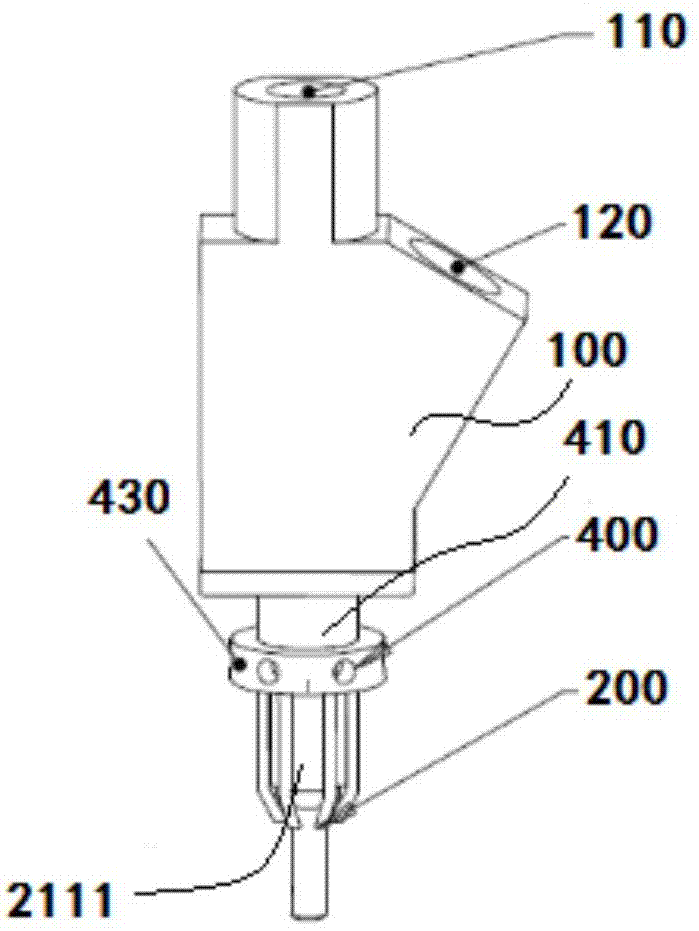

[0034] This embodiment provides a clamping device for screw locking, please refer to figure 1 , the clamping device for screw locking includes a base 100 , an inner clamping structure 200 and an outer clamping structure 300 .

[0035] Wherein, the inner clamping structure 200 is used to clamp the outer circumference of the screw, and the inner clamping structure 300 is connected to the base 100 . The outer layer clamping structure 300 is used to clamp the outer circumference of the screw, the outer layer clamping structure 300 is coaxially arranged with the inner layer clamping structure 200 and sleeved on the outer circumference of the inner layer clamping structure 200, the outer layer clamping structure 300 The bottom is lower than the bottom of the inner clamping structure 200 .

[0036] In this way, due to the existence of the inner layer clamping structure 200 and the outer layer clamping structure 300, and the outer layer clamping structure 300 is coaxially arranged wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com