Full-automatic tapping device

A fully automatic, vibrating disc technology, applied in the field of machining, can solve the problems of tap breakage, affecting the tapping effect, dislocation, etc., to achieve the effect of improving processing efficiency, saving manpower and material resources, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with embodiment, the present invention will be further described:

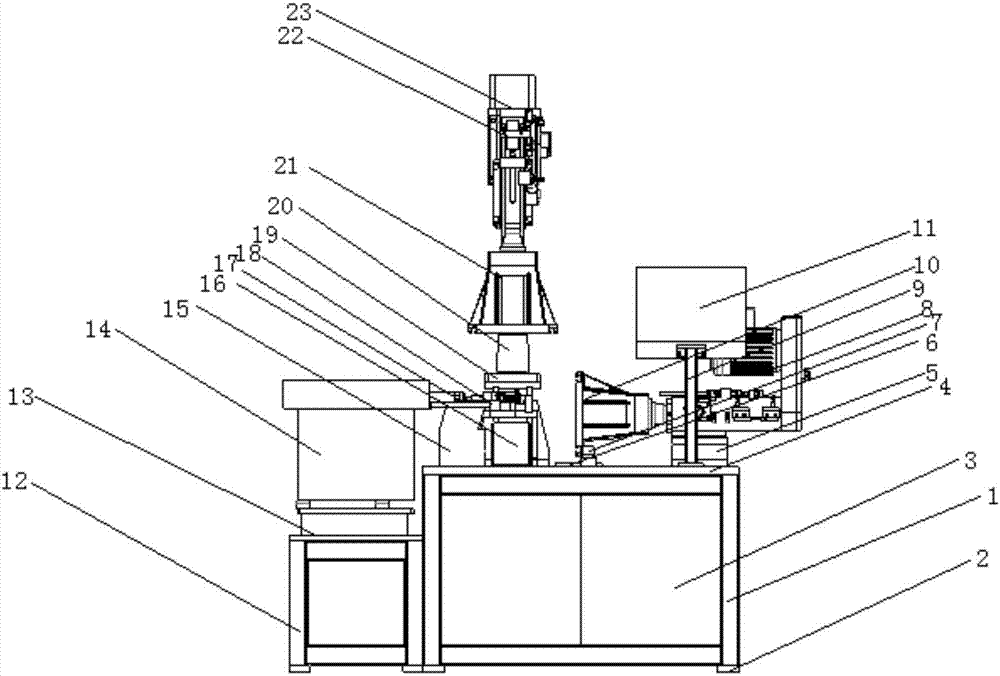

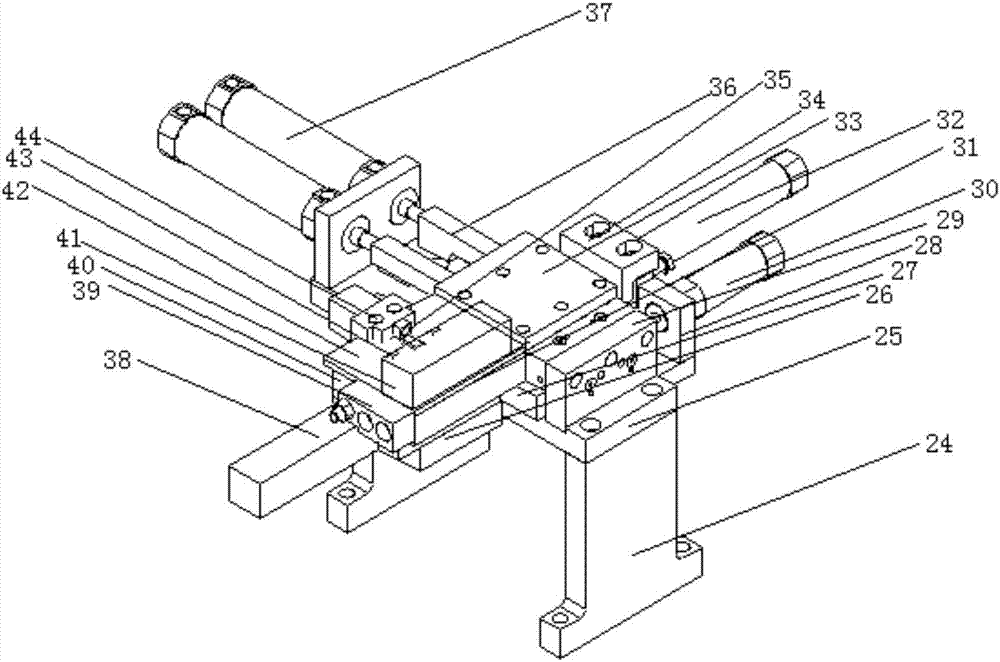

[0015] like figure 1 As shown, a fully automatic tapping device includes a workbench 1, which is characterized in that: the workbench 1 is in the shape of a cuboid, the bottom of the workbench is provided with feet 2, the side of the workbench is provided with double doors 3, and the workbench 1 is provided with a mechanical bottom plate 4 on the table, a chip drop opening is set in the middle of the mechanical bottom plate, two tracks 6 are set on the right side of the chip drop opening, and a horizontal pad 5 is set on the far right side of the track line. A horizontal drilling machine 8 is arranged above the height block, and a first multi-axis device 10 is installed on the rotating shaft of the horizontal drilling machine 8, and a guide block 7 is arranged on both sides of the first multi-axis device 10, and the guide block 7 are slidingly connected with the two track lines res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com