Stirring device easy to feed during operation

A stirring device and operation process technology, applied to mixers with rotating stirring devices, transportation and packaging, mixer accessories, etc., can solve the problem of slowness, inability to accurately control the content of ingredients, and easy to fall to the non-stop rotating stirring claws problems such as above, to achieve the effect of improving efficiency and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

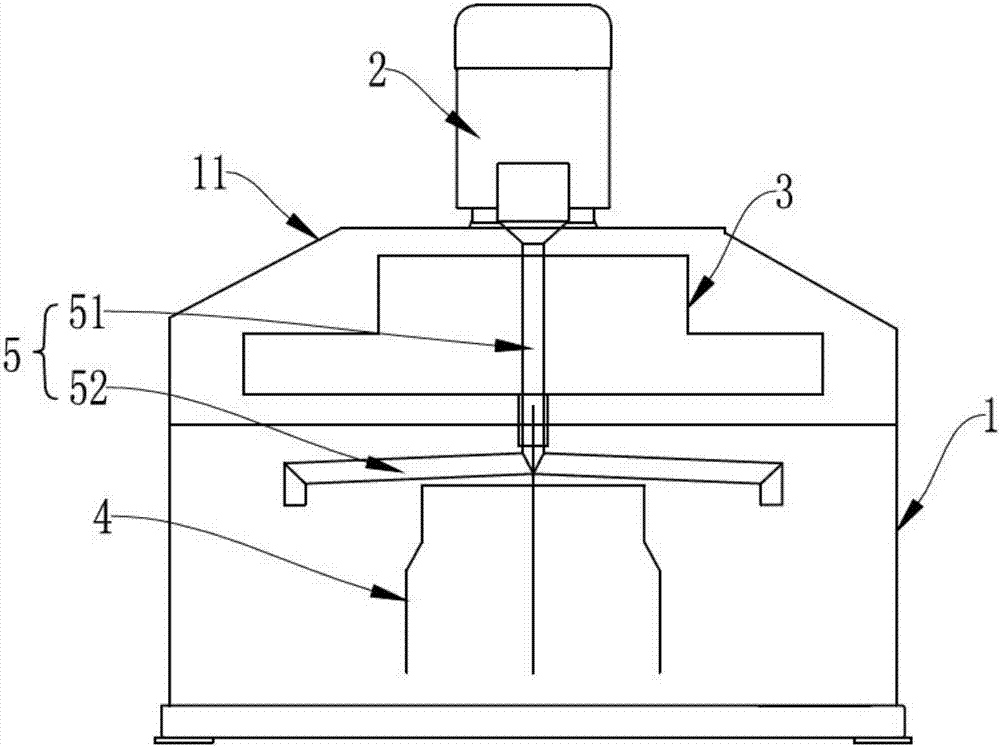

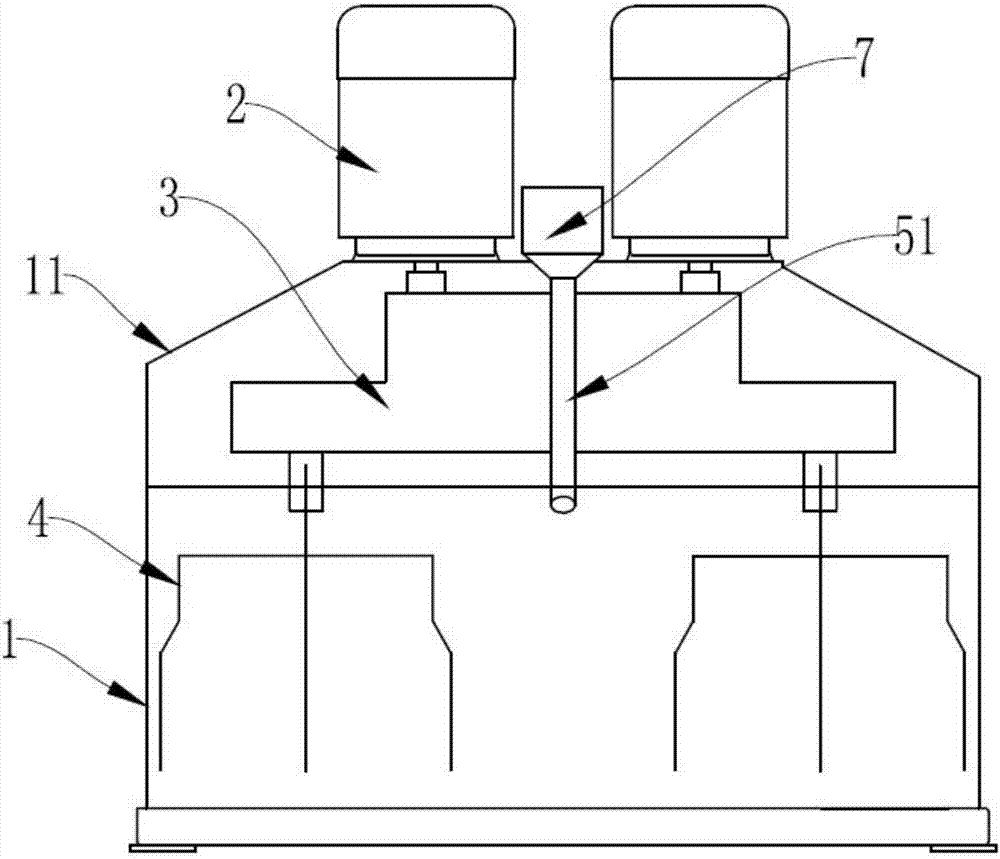

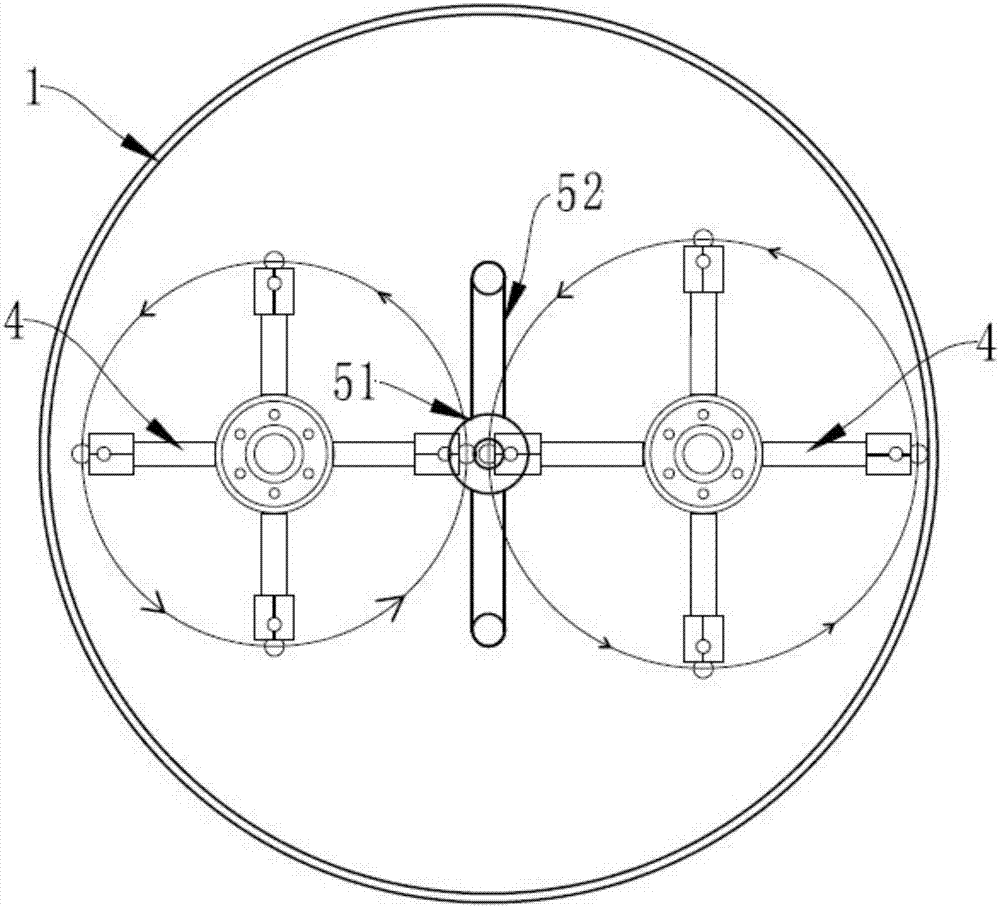

[0031] Such as figure 1 , figure 2 and image 3 As shown, a stirring device that facilitates feeding during operation; includes a mixing chamber 1, a driving device 2, a revolving transmission member 3, a stirring claw 4 and a feeding assembly 5, and the driving device 2 is installed on the mixing chamber. Cavity 1;

[0032] The stirring claw 4 is arranged on the revolution transmission part 3, the driving device 2 drives the revolution transmission part 3 to rotate, and the stirring claw 4 stirs the material in the mixing chamber 1;

[0033] The feed assembly 5 includes a main feed channel 51 and one or more feed branch channels 52;

[0034] The main feed channel 51 passes through the middle of the revolution transmission member 3 and can rotate synchronously with the revolution transmission m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com